Quality production video monitoring system

A video surveillance system and video surveillance technology, applied in closed-circuit television systems, televisions, instruments, etc., can solve problems such as low production efficiency, reduce the probability of quality problems, reduce the error rate, and eliminate the effect of irregular operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

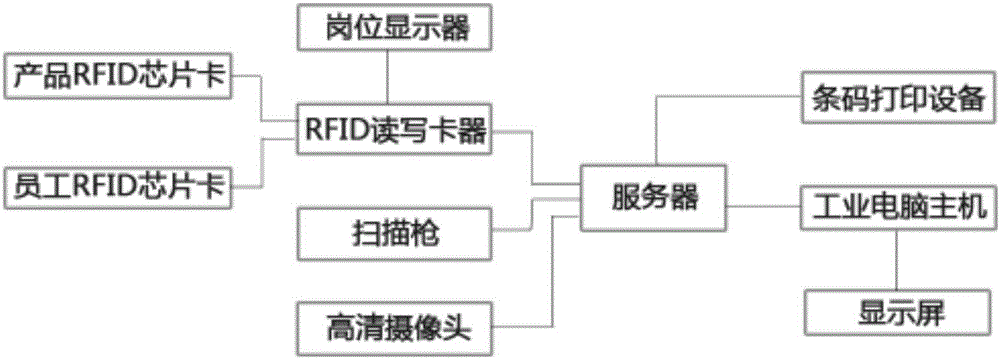

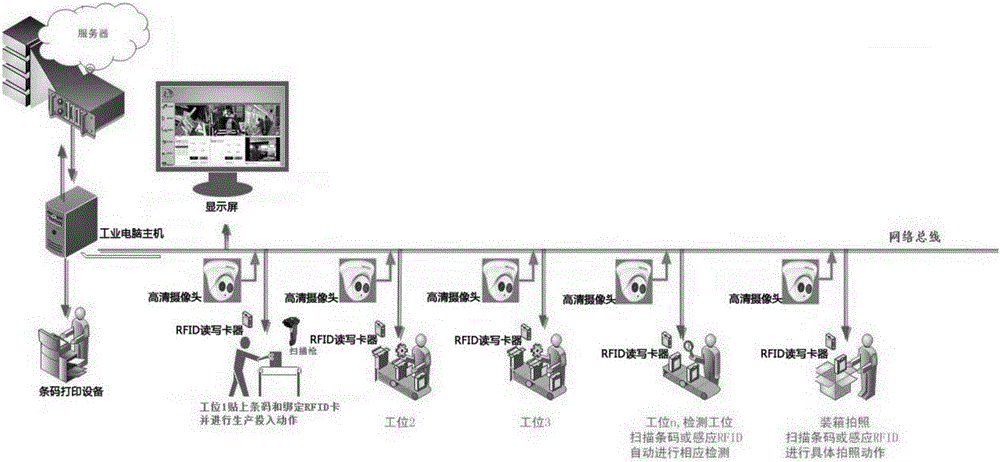

[0021] refer to figure 1 with figure 2 , propose an embodiment of a quality production video monitoring system of the present invention:

[0022] A video monitoring system for quality production, including an industrial computer host with a built-in video monitoring client query system, a display screen connected to the industrial computer host, and a monitor connected to the industrial computer host for storing various monitoring data and monitoring various production lines. The server for information processing and network communication, the barcode printing device for printing barcodes to be pasted on the product shell, and the monitoring terminal for communication connection with the industrial computer host. The monitoring terminal includes the product RFID chip card installed on each post tooling board of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com