Recycling method of power lithium-ion batteries

A lithium-ion battery and power technology, which is applied in the field of lithium battery recycling and new energy, and can solve the problems of improper recycling method and harmful exhaust gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] With the battery in the comparative example (1C discharge capacity is the battery of 650mAh), discharge to 3.0V with 650mA electric current first, under the environment that relative humidity is lower than 2%, the liquid injection port of battery is opened, injects 0.98g lithium hexafluorophosphate electrolyte ( 1.5g per ampere hour), the injection of the electrolyte is carried out twice, each injection of 0.49g of electrolyte, each time after the electrolyte is injected, it needs to be vacuumed, and each vacuum is completed through the following three steps in sequence: -30KPa vacuuming for 60s; -60KPa vacuuming for 60s; -90KPa vacuuming for 60s;

[0034] After the electrolyte is completely infiltrated, charge and form with a predetermined current of 0.05~0.2C. The charge and form are completed in the following three steps: charge with a current of 0.05 for 120 minutes and rest for 5 minutes; then charge with 0.1C for 240 minutes and rest for 5 minutes; C charge for 60...

Embodiment 2

[0037] The amount of electrolyte added in Example 1 was changed from 0.98g to 1.56g (2.4g per ampere hour), and the other production methods were the same as in Example 1, and then tested. The results are shown in the following test instructions.

Embodiment 3

[0039] The amount of electrolyte added in Example 1 was changed from 0.98g to 1.95g (3.0g per ampere hour), and the other production methods were the same as in Example 1, and then the test was carried out. The results are shown in the following test description.

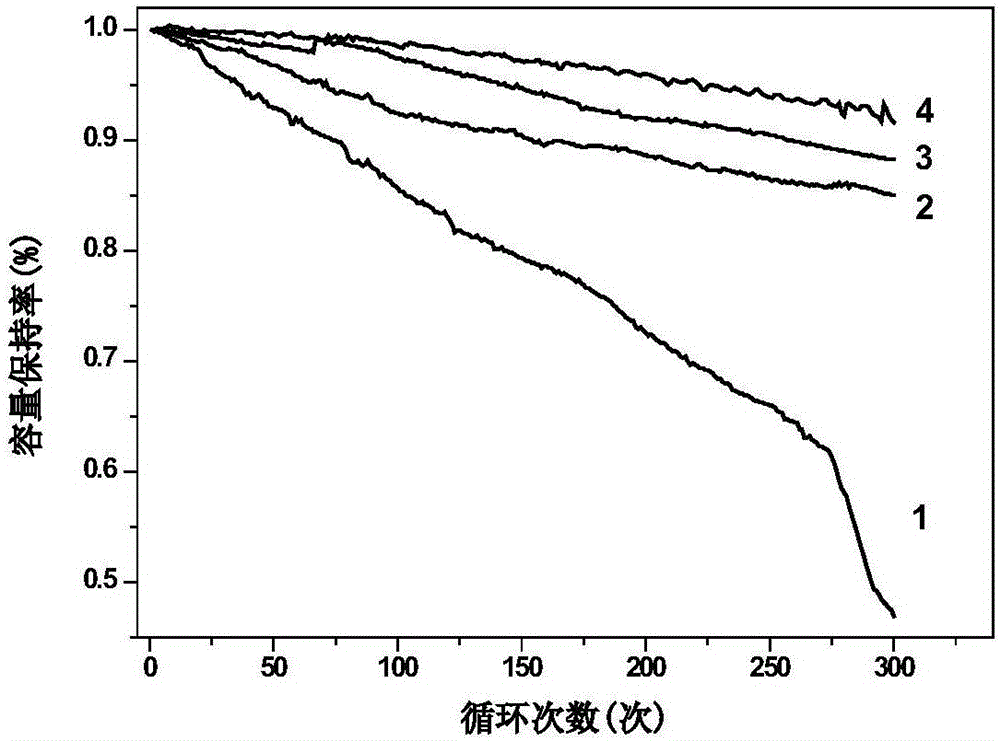

[0040] test introduction:

[0041] 1. Capacity test

[0042]Test method: at 25°C, fully charge to 4.2V with 650mA current, leave it for 5 minutes, and then discharge to 3.0V with 650mA current.

[0043] For each group of embodiments, all removed batteries with a 1C discharge capacity of 650mA are used to make batteries according to the implementation methods of each group. After the battery is manufactured, the capacity is tested according to the above test method, and the results show that:

[0044] In the comparative example, the battery 1C discharge capacity is 650mAh, the battery 1C discharge capacity of Example 1 is 716mAh, the implementation 2 battery 1C discharge capacity is 743mAh, and the implementation 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com