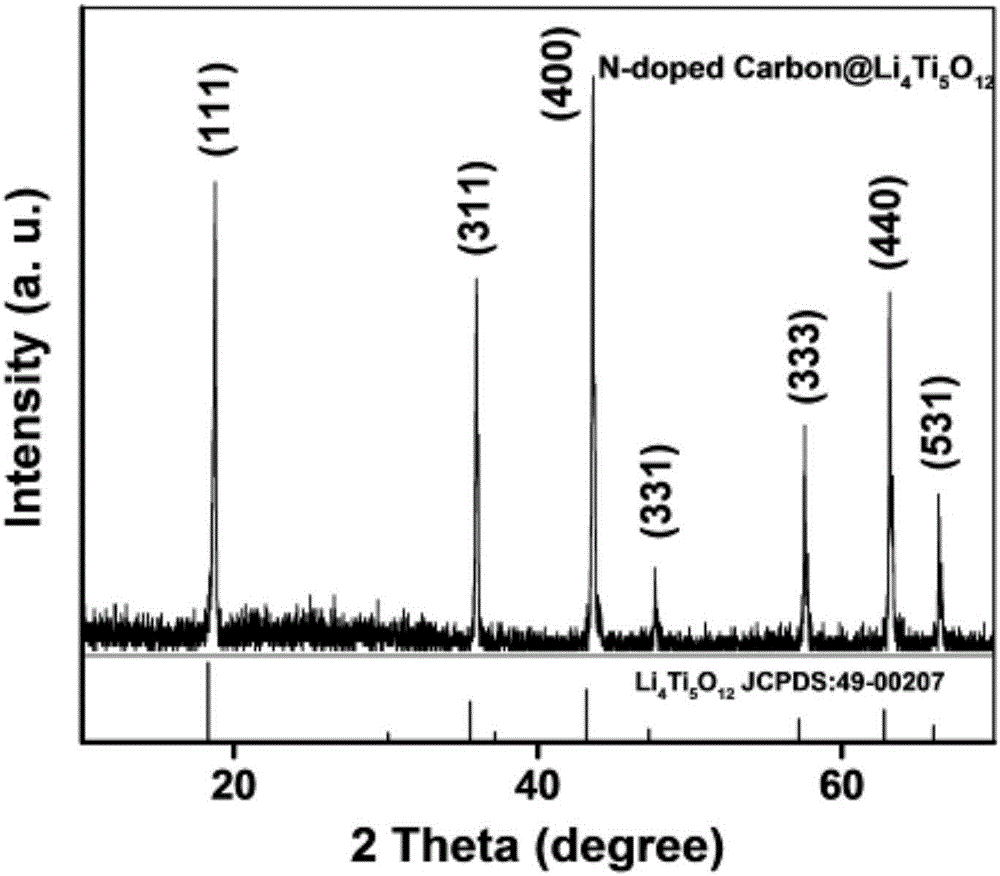

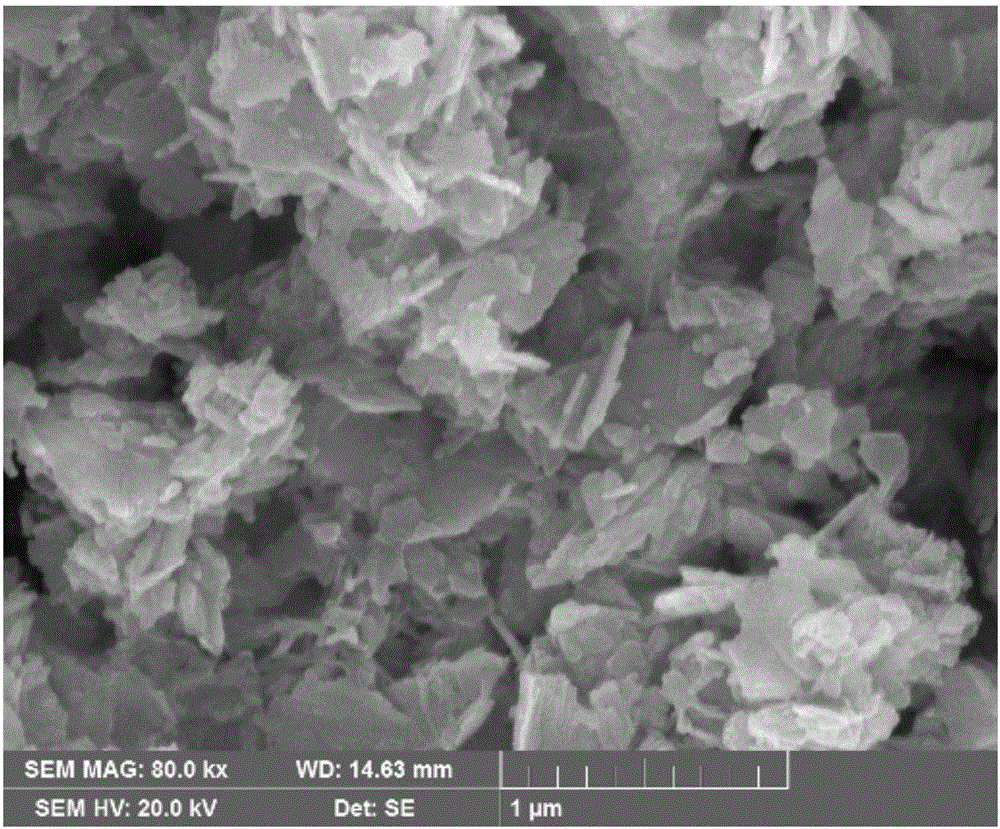

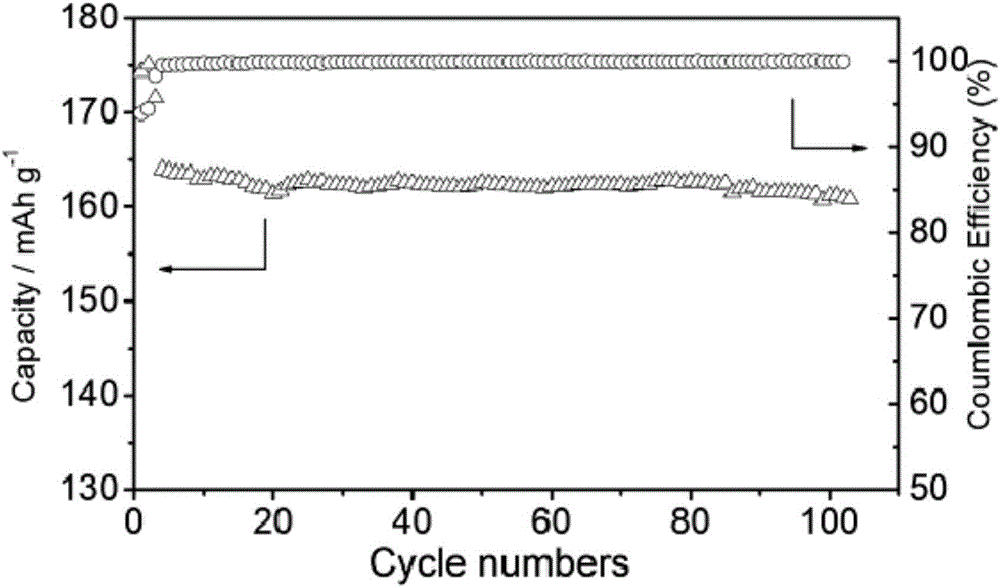

In-situ nitrogen-doped carbon coated lithium titanate composite electrode material and preparation method thereof

A technology of carbon-coated lithium titanate and composite electrodes, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as poor conductivity, and achieve the effects of promoting energy storage performance, improving conductivity, and promoting charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Add 40ml (13.6g) of tetrabutyl titanate (TBT) into 40ml of absolute ethanol, stir well to completely dissolve in the ethanol solution, and prepare mixed solution A. Then take 0.756g lithium hydroxide (LiOH·H 2 O) Dissolve in 40ml of distilled water and stir continuously with a glass rod until the lithium hydroxide is completely dissolved to make solution B. Slowly add solution B to solution A drop by drop, and use a constant temperature magnetic stirrer to continuously stir during the dropwise addition to prevent flocculation due to the continuous increase of viscosity. After the dropwise addition was completed, stirring was continued on a magnetic stirrer for 1 h, and then the mixed solution was transferred to a 100 ml hydrothermal reaction kettle and heated at 180° C. for 24 h. After the reaction was completed, it was cooled to room temperature, filtered, and the filter cake was washed repeatedly with water and absolute ethanol to obtain a white solid, which was d...

Embodiment 2

[0041] 1) Add 40ml (13.6g) of tetrabutyl titanate (TBT) into 40ml of absolute ethanol, stir well to completely dissolve in the ethanol solution, and prepare mixed solution A. Then take 0.756g lithium hydroxide (LiOH·H 2 O) Dissolve in 40ml of distilled water and stir continuously with a glass rod until the lithium hydroxide is completely dissolved to make solution B. Slowly add solution B to solution A drop by drop, and use a constant temperature magnetic stirrer to continuously stir during the dropwise addition to prevent flocculation due to the continuous increase of viscosity. After the dropwise addition was completed, stirring was continued on a magnetic stirrer for 1 h, and then the mixed solution was transferred to a 100 ml hydrothermal reaction kettle and heated at 180° C. for 24 h. After the reaction was completed, it was cooled to room temperature, filtered, and the filter cake was washed repeatedly with water and absolute ethanol to obtain a white solid, which was d...

Embodiment 3

[0046] 1) Add 40ml (13.6g) of tetrabutyl titanate (TBT) into 40ml of absolute ethanol, stir well to completely dissolve in the ethanol solution, and prepare mixed solution A. Then take 0.756g lithium hydroxide (LiOH·H 2O) Dissolve in 40ml of distilled water and stir continuously with a glass rod until the lithium hydroxide is completely dissolved to make solution B. Slowly add solution B to solution A drop by drop, and use a constant temperature magnetic stirrer to continuously stir during the dropwise addition to prevent flocculation due to the continuous increase of viscosity. After the dropwise addition was completed, stirring was continued on a magnetic stirrer for 1 h, and then the mixed solution was transferred to a 100 ml hydrothermal reaction kettle and heated at 200° C. for 24 h. After the reaction was completed, it was cooled to room temperature, filtered, and the filter cake was washed repeatedly with water and absolute ethanol to obtain a white solid, which was dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com