Composite negative electrode material, preparation method and lithium battery

A technology for negative electrode materials and raw materials, which is applied in the field of composite negative electrode materials and their preparation, can solve the problems of low conductivity and poor rate performance of silicon-based materials, and achieve high specific capacity, improve rate performance, and inhibit the effects of cracking and pulverization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

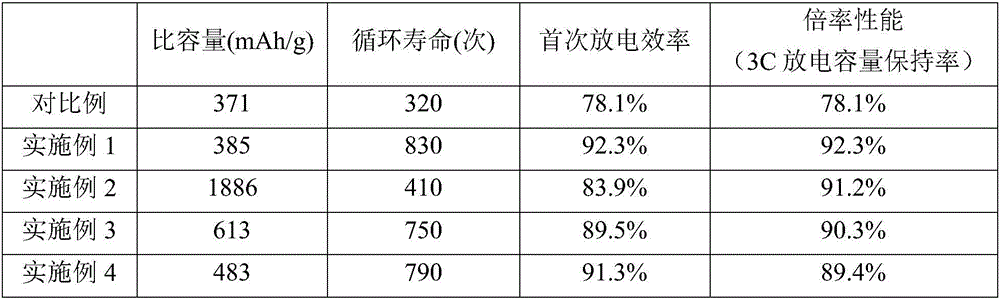

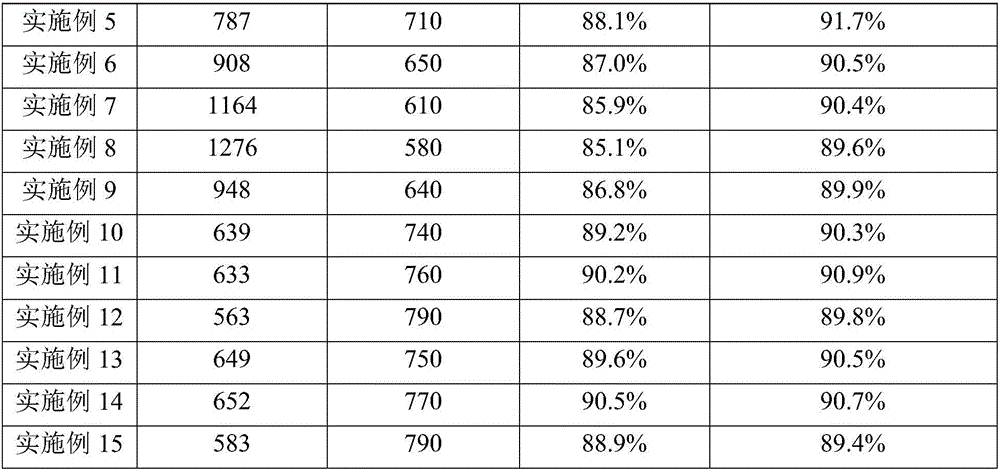

Examples

preparation example Construction

[0024] The preparation method of the composite negative electrode material of the present invention is as follows: the nitrogen precursor, the carbon precursor and the copper salt are dissolved in a solvent to form a mixed solution, and the solvent is at least one of water or ethanol; in the mixed solution, the mass of the nitrogen precursor The percentage concentration is 0.1% to 20%, the mass percentage concentration of the carbon precursor is 0.1% to 20%, and the mass percentage concentration of the copper salt is 0.1% to 20%. The ratio of graphite and silicon-based raw materials is 50: Mix at a ratio of 50 to 99:1, then add to the prepared mixed solution, stir evenly to obtain a slurry mixture, then react the slurry mixture in a high-pressure reactor at 100°C to 300°C for 1 to 24 hours, and then cool , filtering and drying to obtain a solid mixture, and calcining the solid mixture at 500-1000° C. for 1-12 hours in a high-temperature furnace under the protection of an inert ...

Embodiment 1

[0032] Dissolving melamine, glucose and copper nitrate in water to form a mixed solution, the mixed solution has a concentration of 0.1% by mass of melamine, 5% by mass of glucose, and 1% by mass of copper nitrate;

[0033] After mixing the graphite and silicon powder in a mass fraction ratio of 99:1, immerse in the prepared mixed solution, and stir evenly to obtain a slurry-like mixture;

[0034] The prepared slurry mixture was reacted at 100°C for 24 hours in a high-pressure reactor, then cooled, filtered to remove the solvent and dried to obtain a solid mixture;

[0035] The solid mixture was calcined at 500° C. for 12 hours in a high-temperature furnace under the protection of nitrogen to obtain a composite negative electrode material.

[0036] The composite negative electrode material is used to make a negative electrode sheet by conventional technology, and is matched with a conventional positive electrode sheet, a conventional separator, and a conventional electrolyte t...

Embodiment 2

[0038] Ammonia, starch and copper chloride are dissolved in water to form a mixed solution, the mass percentage concentration of ammonia in the mixed solution is 20%, the mass percentage concentration of starch is 20%, and the mass percentage concentration of copper chloride is 0.1%;

[0039] After mixing graphite and silicon oxide powder at a mass ratio of 50:50, immerse in the mixed solution, and stir evenly to obtain a slurry-like mixture;

[0040] The slurry mixture was reacted at 150°C for 1 h in an autoclave, cooled, filtered to remove the solvent and dried to obtain a solid mixture;

[0041] The solid mixture was calcined in a high-temperature furnace at 700° C. for 3 hours under the protection of nitrogen to obtain a composite negative electrode material.

[0042] The composite negative electrode material is used to make a negative electrode sheet by conventional technology, and is matched with a conventional positive electrode sheet, a conventional separator, and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com