A high voltage relay

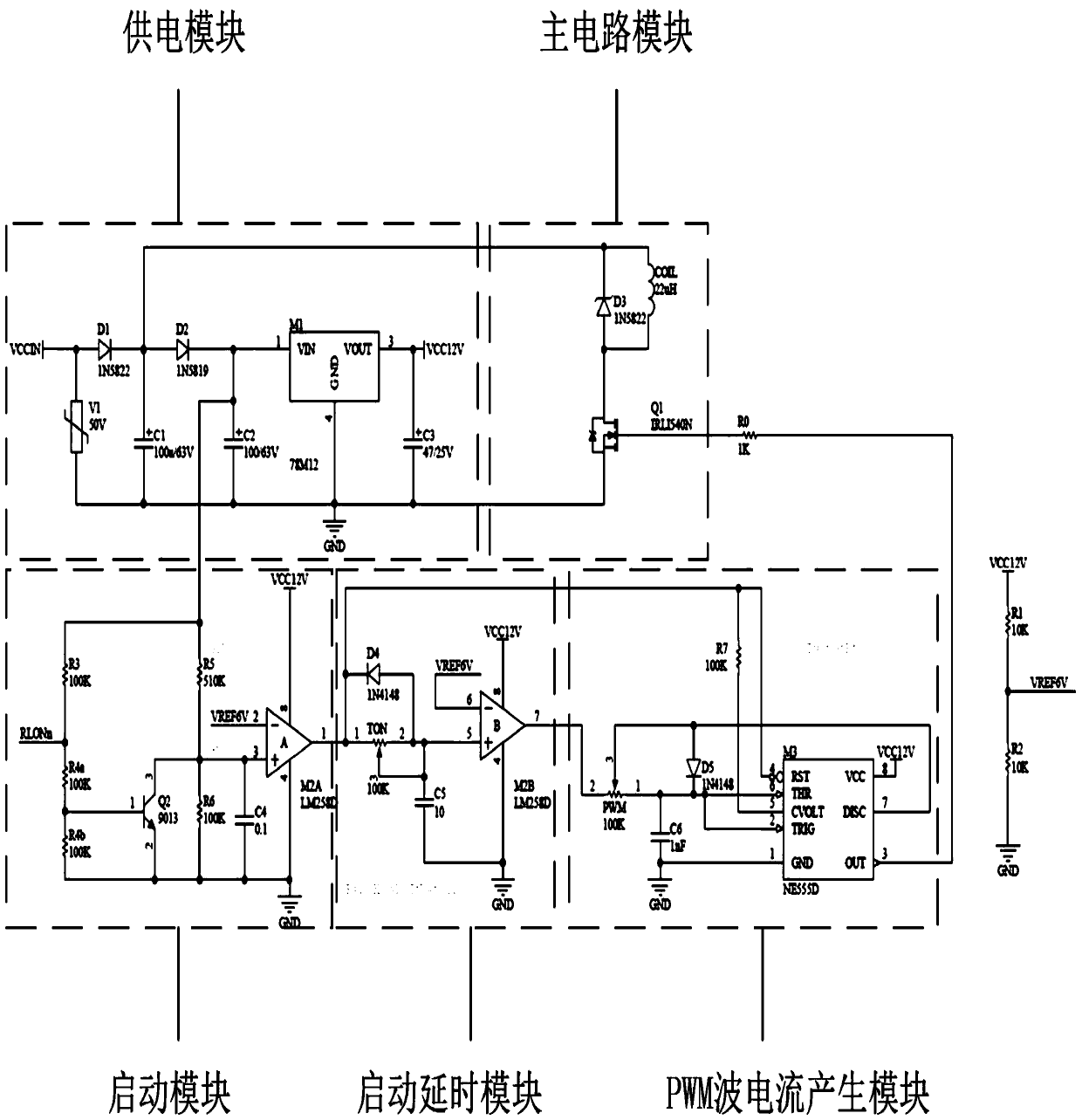

A technology of high-voltage relays and relays, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of high power consumption, heating of relay coils, and inability to use multiple relays at the same time, so as to reduce power consumption and switch reliably Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the present invention, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments herein.

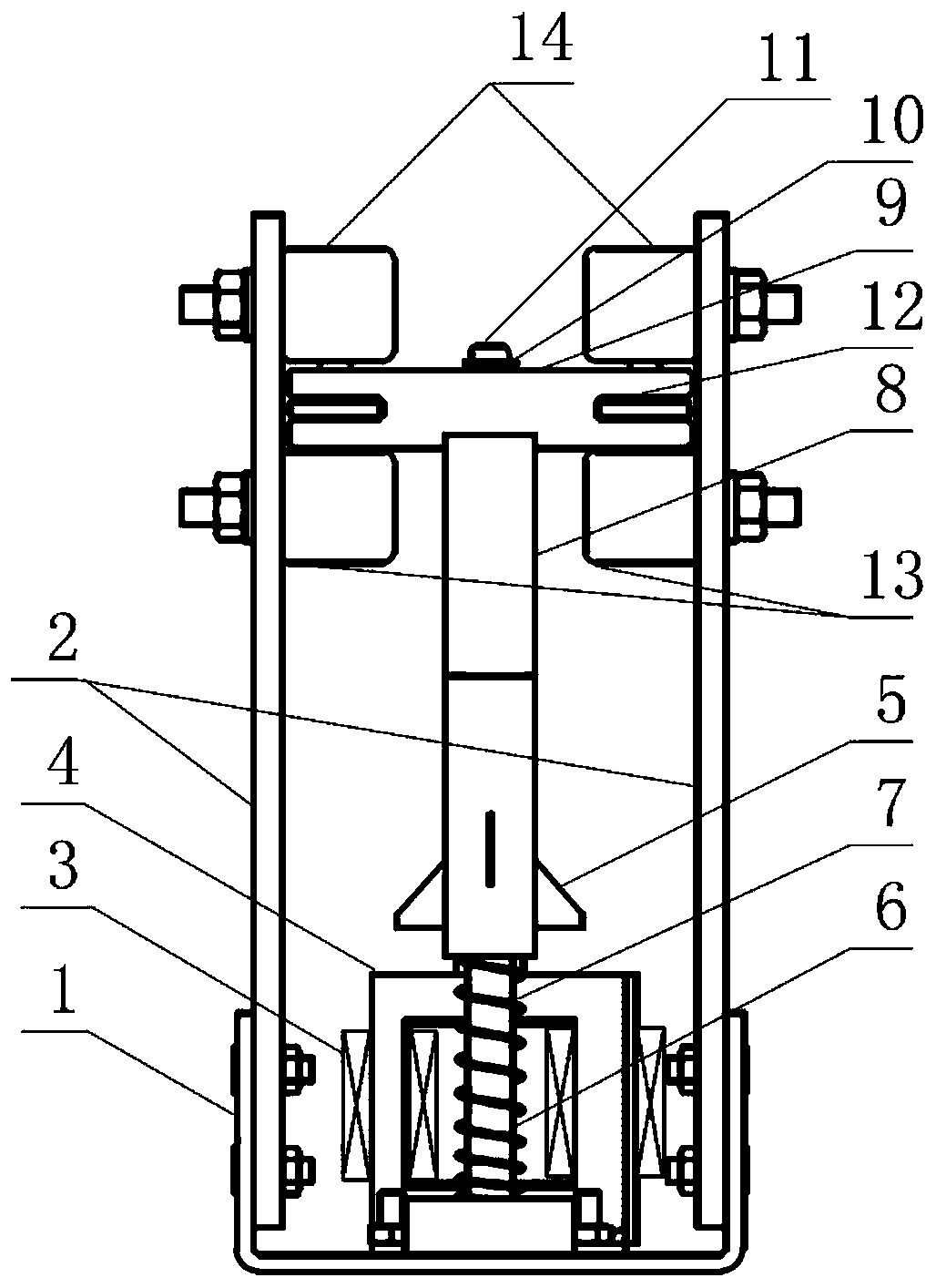

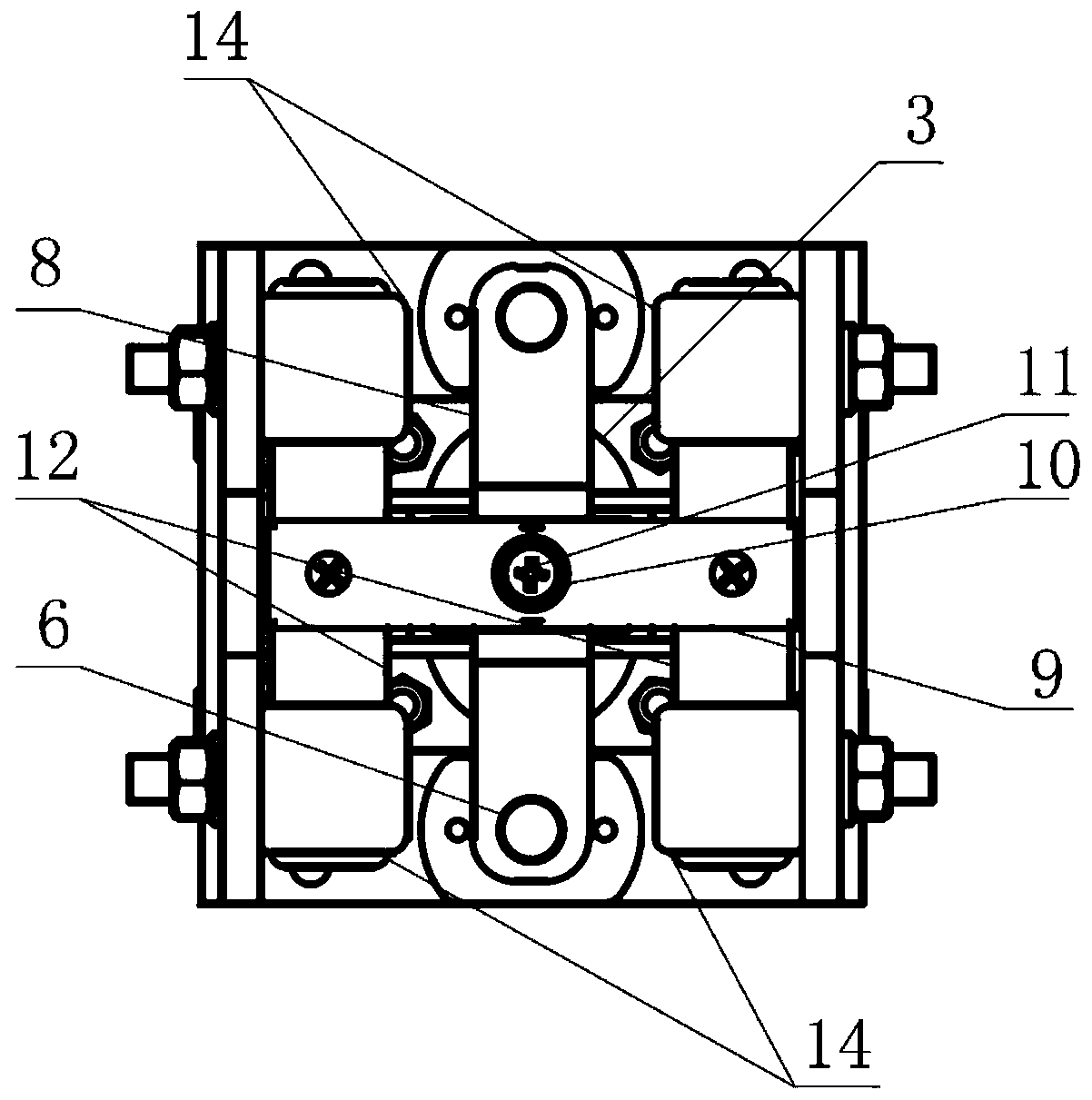

[0017] In one embodiment, the present invention discloses a high-voltage relay, which includes: a bottom plate, a first contact bracket, a second contact bracket, a first compression spring bracket, a second compression spring bracket, a first compression spring , the second compression spring, guide sliding frame, contact knife holder, contact knife, normally open contact, normally closed contact, yoke, armature, control board;

[0018] The bottom plate is used to support the contact bracket and the yoke;

[0019] The first and second contact brackets are used to support normally open contacts and normally closed contacts;

[0020] The first and second compression spring brackets are used to enable the first and second compression springs and the guide sliding frame to achieve compression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com