Thermal desorption, gas-phase separation and thermal cracking system based on ethylation derivation of methyl mercury

A technology of ethylation derivatization and gas-phase separation, applied in the field of analysis devices, can solve the problems of high degree of integration, difficulty in combining detectors, high price, etc., and achieves the effects of reducing cost, simple operation and saving analysis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

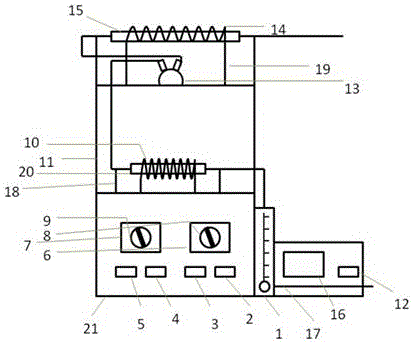

[0026] like Figure 1-5 As shown, in the embodiment of the present invention, the methylmercury thermal analysis-gas phase separation-pyrolysis system based on ethylation derivative includes a thermal analysis part, a gas phase separation part, a thermal cracking part and other parts. This system integrates thermal analysis, gas phase separation and pyrolysis, and can be controlled separately, with low cost, simple operation and high analysis efficiency.

[0027] The thermal analysis part includes: thermal analysis heating wire switch 4, thermal analysis heating wire control time switch 5, thermal analysis heating wire voltage regulator 7, thermal analysis heating wire voltage regulator knob 9, thermal analysis heating wire 10, thermal analysis Heating wire support 18, Tenax adsorption tube 20. Its working procedure is to adjust the thermal analysis heating wire voltage regulator 7 by adjusting the thermal analysis heating wire voltage regulator knob 9 on the pressure regulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com