Method for measuring water content of graded broken stone

A technology for grading crushed stone and moisture content, applied in measuring devices, by removing certain components, weighing, instruments, etc., it can solve the problem of large proportion of coarse aggregates, poor water retention performance of coarse aggregates, and proportion of fine aggregates. Bigger than other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

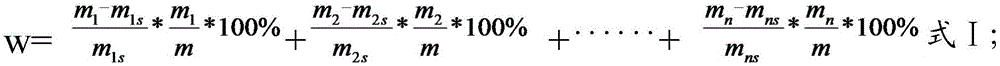

Method used

Image

Examples

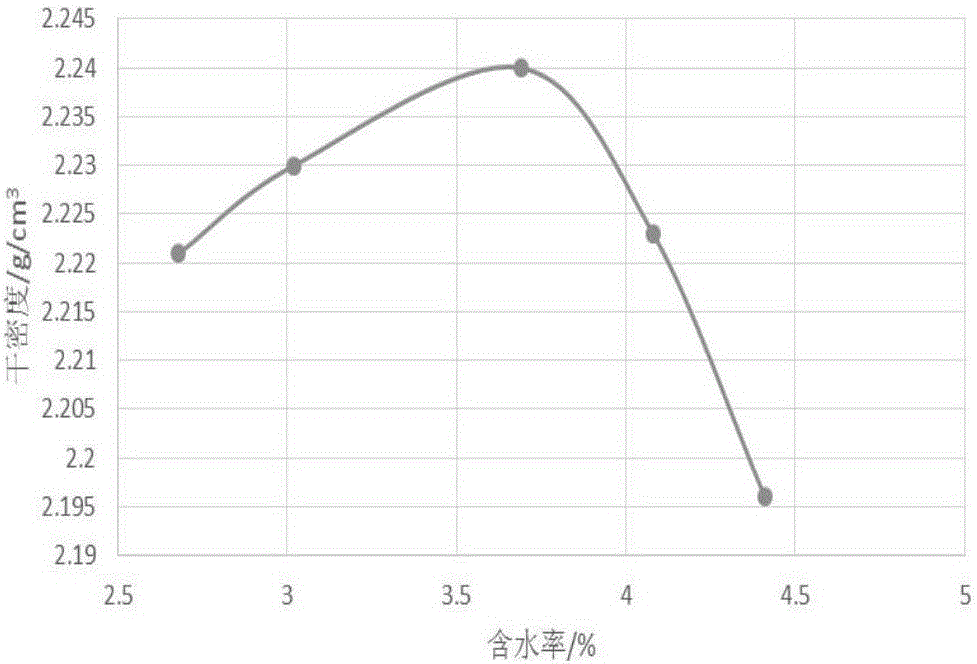

Embodiment 1

[0057] First weigh the mass of the compaction cylinder with an inner diameter of 152mm to be 3250.0g, then select the graded crushed stone sample to be tested with 3.0% estimated moisture content, and charge according to the three-layer method, and compact each layer 98 times . After the compaction is completed, use a repair knife to scrape the surface of the graded gravel along the edge of the compaction cylinder. Finally, the total mass of the compaction cylinder and the sample in the cylinder was weighed to be 8211.4g, and the mass of the graded crushed stone to be tested was 4961.4g.

[0058] Use a bulldozer to push out the graded crushed stone specimens in the compaction cylinder, put them into a shallow pan and crush them, and use the quartering method to quickly divide them into four parts, which are numbered 1, 2, 3 and 4 respectively, and measure the corresponding numbered crushed stones The sample masses are: 1065.3g, 1125.8g, 1358.7g and 1411.6g respectively.

[0...

Embodiment 2

[0063] First weigh the mass of the compaction cylinder with an inner diameter of 152mm to be 3250.0g, then select the graded crushed stone sample to be tested with 3.5% estimated moisture content, and charge according to the three-layer method, and compact each layer 98 times . After the compaction is completed, use a repair knife to scrape the surface of the graded gravel along the edge of the compaction cylinder. Finally, the total mass of the compaction cylinder and the sample in the cylinder was weighed to be 8251.3g, and the mass of the graded crushed stone to be tested was 5001.3g.

[0064] Use a bulldozer to push out the graded crushed stone specimens in the compaction cylinder, put them into a shallow pan and crush them, and use the quartering method to quickly divide them into four parts, which are numbered 1, 2, 3 and 4 respectively, and measure the corresponding numbered crushed stones The sample masses are: 1265.3g, 1232.3g, 1320.7g and 1183.0g respectively.

[0...

Embodiment 3

[0069] First weigh the mass of the compaction cylinder with an inner diameter of 152mm to be 3250.0g, then select the graded crushed stone sample to be tested with 4.0% estimated moisture content, and charge according to the three-layer method, and compact each layer 98 times . After the compaction is completed, use a repair knife to scrape the surface of the graded gravel along the edge of the compaction cylinder. Finally, the total mass of the compaction cylinder and the sample in the cylinder was weighed to be 8306.4g, and the mass of the graded crushed stone to be tested was 5056.4g.

[0070] Use a bulldozer to push out the graded crushed stone specimens in the compaction cylinder, put them into a shallow pan and crush them, and use the quartering method to quickly divide them into four parts, which are numbered 1, 2, 3 and 4 respectively, and measure the corresponding numbered crushed stones The sample masses are: 1362.3g, 1209.6g, 1196.5g and 1288.0g respectively.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com