Device and method for detecting contours of large-caliber aspheric surface components

An aspheric, large-diameter technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of insufficient use of spatial reference motion error compensability, limited surface measurement accuracy, and limited response speed. Small deformation, short motion amplitude, and the effect of reducing Abbe error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] like figure 1 and figure 2 As shown, the detection method for the contour processing of large-diameter aspheric elements, the detection steps are as follows:

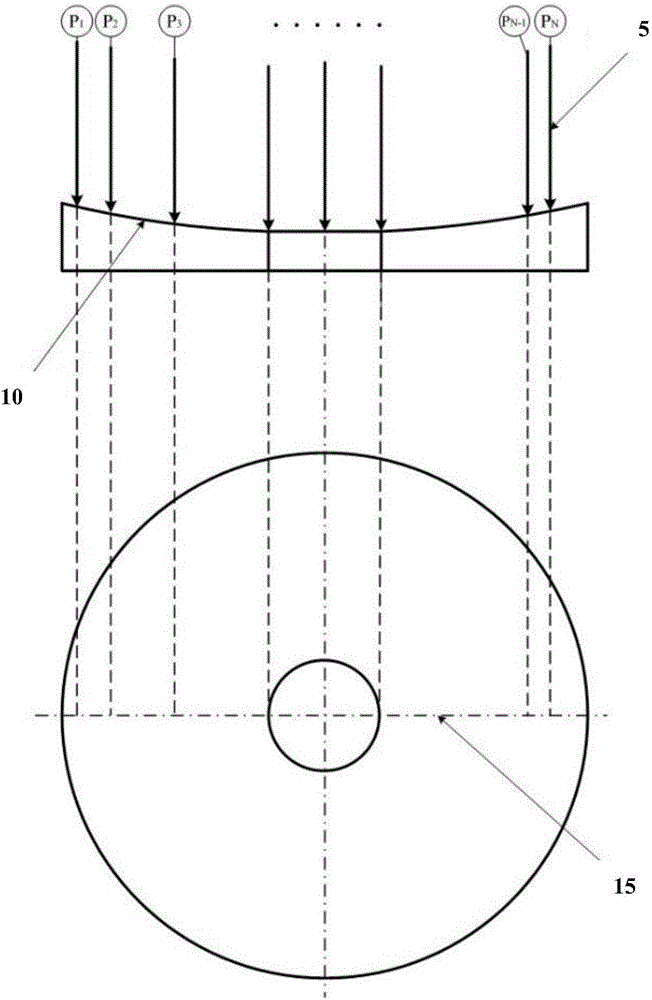

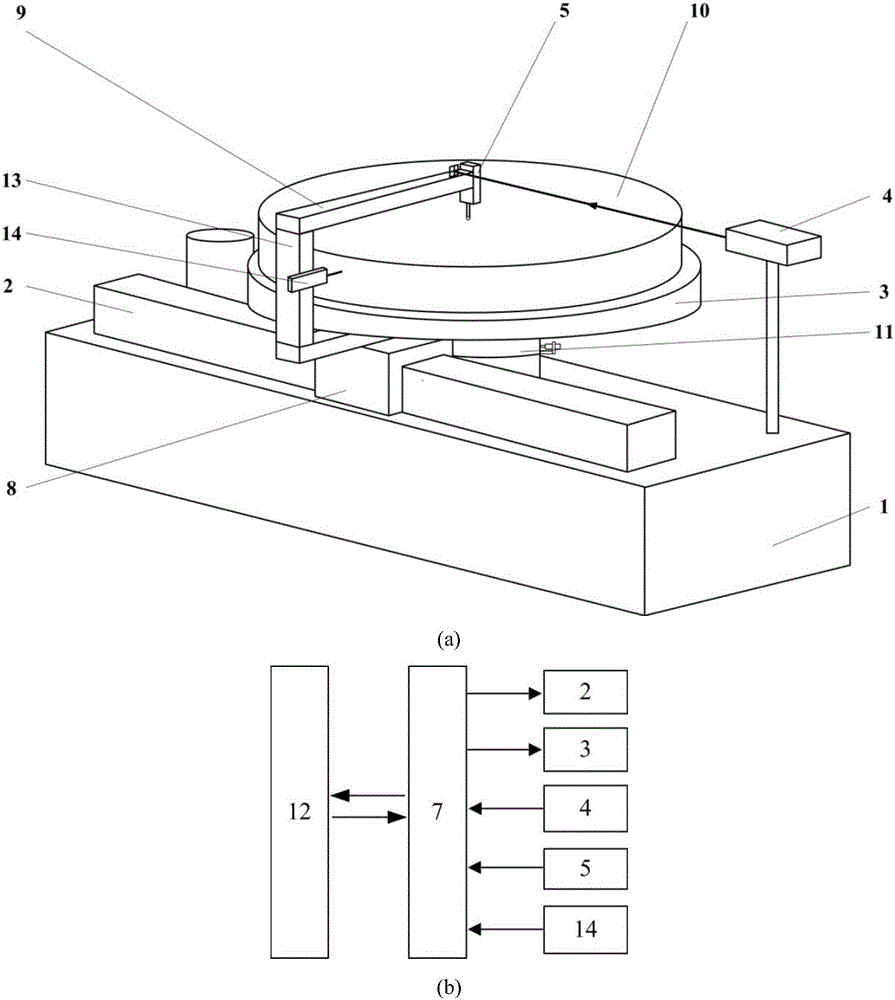

[0042] The measured aspheric surface 10 is placed on the precision air-floating rotary table 3, and the sensor measurement system 5 is fixed on the horizontal measuring arm 9 connected to the bushing 8 of the precision linear air-floating guide rail 2, and can be used as a joint with the bushing 8. In the measurement process, it is necessary to ensure that the sensing and measuring system 5 is perpendicular to the motion direction of the precision linear air-bearing guide rail 2, and the sensing and measuring system 5 performs a one-dimensional scanning linear motion along the generatrix direction 15 of the measured aspheric surface 10, and at the same time Using the guide rail linear motion error laser monitoring system 4 to monitor, separate and compensate the linear motion error of the precision linear air-f...

Embodiment 2

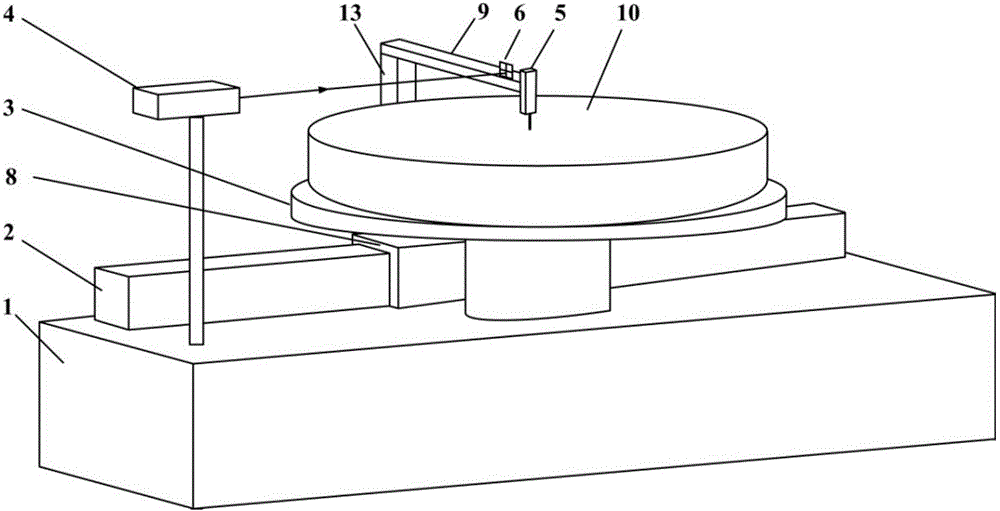

[0047] combine figure 1 and image 3 As shown, the large-diameter aspheric surface processing and testing device is mainly composed of base 1, precision linear air-floating guide rail 2, precision air-floating rotary table 3, guide rail linear motion error laser monitoring system 4, air-floating table adjustment system 11, measurement transmission Sensing system 5, control system 7, computer 12, etc., precision linear air-floating guide rail 2, guide rail linear motion error laser monitoring system 4 are all fixed on the base 1, and distributed around the precision air-floating rotary table 3. Among them, the sensing and measuring system 5 is fixed on the transverse measuring arm 9 connected with the shaft sleeve 8 of the precision linear air bearing guide rail 2, and can perform a one-dimensional linear scanning movement along the axial direction of the precision linear air bearing guide rail 2 along with the sleeve 8 ; The radial sensing system 14 is fixed on the vertical m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com