Air cooling unit steam turbine waste heat using system and method

A technology for air-cooling units and steam turbines, applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of corrosion, low energy grade of waste heat utilization, and complex systems, and achieve the effect of preventing low-temperature corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

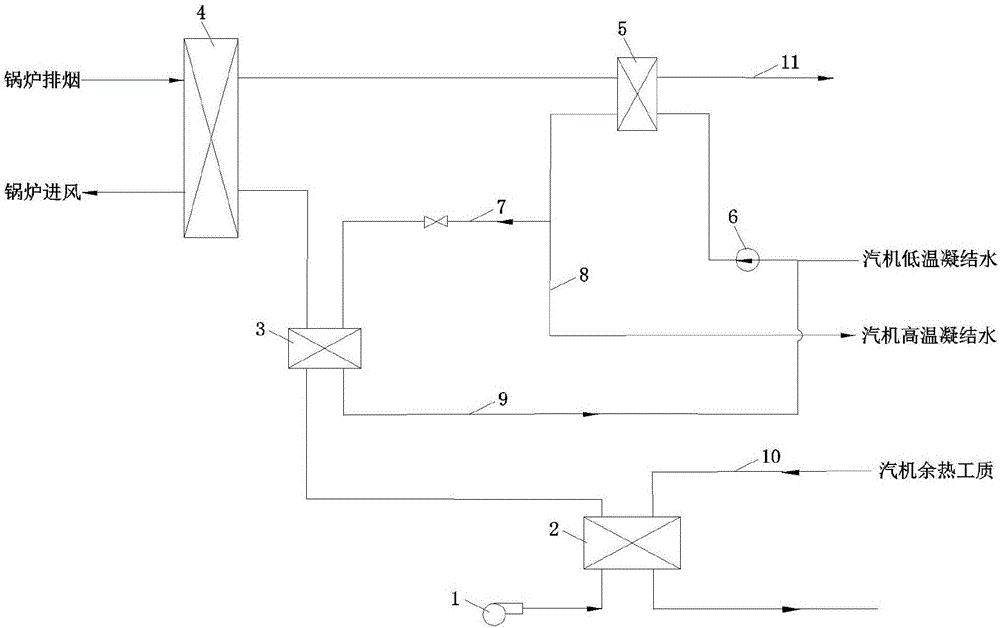

[0024] as attached figure 1 As shown, the steam turbine waste heat utilization system of the air-cooled unit in this embodiment includes a cold air preheater 2 and a heater 3 installed on the air duct between the boiler cold air fan 1 and the air side inlet of the air preheater 4, and installed on the air preheater 4. The smoke-water heat exchanger 5 between the flue gas side outlet and the dust remover flue 11 is connected to the steam turbine waste heat working medium pipeline 10 of the cold air preheater 2, connected to the smoke-water heat exchanger 5, and the condensate booster pump 6. The condensed water inlet and outlet pipelines 7, 8, and 9 of the air heater 3. The connection relationship between the cold air preheater 2 and the steam turbine waste heat working medium pipeline 10 is as follows: the steam turbine waste heat working medium pipeline 10 is connected to the water side or steam side inlet of the cold wind preheater 2 and then flows out, returning to the stea...

Embodiment 2

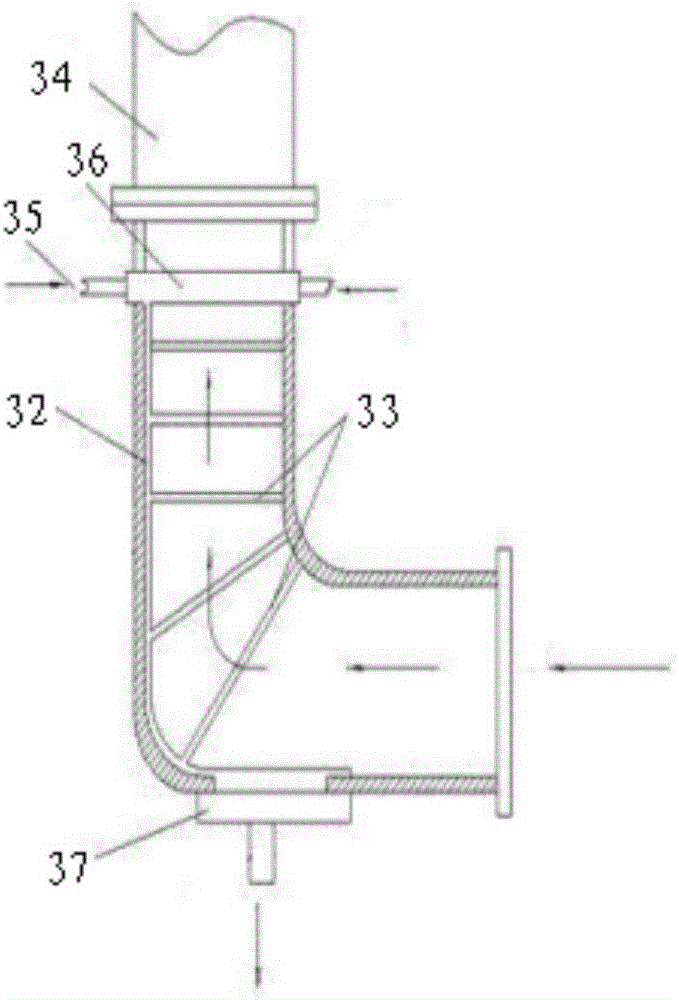

[0026] Such as figure 2 As shown, in this embodiment, the steam turbine waste heat utilization system of the air-cooled unit in this embodiment, on the basis of Embodiment 1, the air heater is located below the inlet air duct 34 of the air preheater, and the outlet air duct of the air heater 1 is connected to the The inlet duct 34 of the air preheater is vertically connected, the membrane heat dissipation pipe row 32 is installed on the air duct wall of the air heater, the fin heat dissipation pipe 33 is installed in the air passage of the air heater, the membrane type heat dissipation pipe row 32 and the fin The air inlet of the fin radiating pipe 33 is communicated with the heater air source 35 through a pipeline.

[0027] In order to make full use of boiler waste heat, a heat source inlet header 36 is installed on the upper part of the heater, and a heat source outlet header 37 is installed on the lower part of the heater. The boiler waste heat pipeline is connected to the...

Embodiment 3

[0030] as attached figure 1 As shown, the method for utilizing the waste heat of the steam turbine of the system air-cooling unit described in Embodiment 1 is:

[0031] The waste heat working medium in the steam turbine waste heat working medium pipeline 10 enters the cold air preheater 2 to heat the boiler cold air and then returns to the turbine side; the boiler cold air passes through the air heater 3 and is reheated by the condensate water from the condensate water pipeline 7, and then enters the air preheater 4 to be discharged Boiler flue exhaust heat, this part of waste heat enters the flue water heat exchanger 5 with the flue gas to heat the low-temperature condensate water of the turbine, and the heated high-temperature condensate part returns to the condensate water system on the turbine side through the condensate water pipeline 8.

[0032] Since the waste heat of the steam turbine is used to heat the cold air of the boiler, the flue gas temperature at the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com