Pipeline butt-joint device capable of adapting to adjustment

A self-adaptive adjustment and docking device technology, which is applied to jet propulsion devices, rocket engine devices, pipes/pipe joints/fittings, etc., can solve problems such as matching and error sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

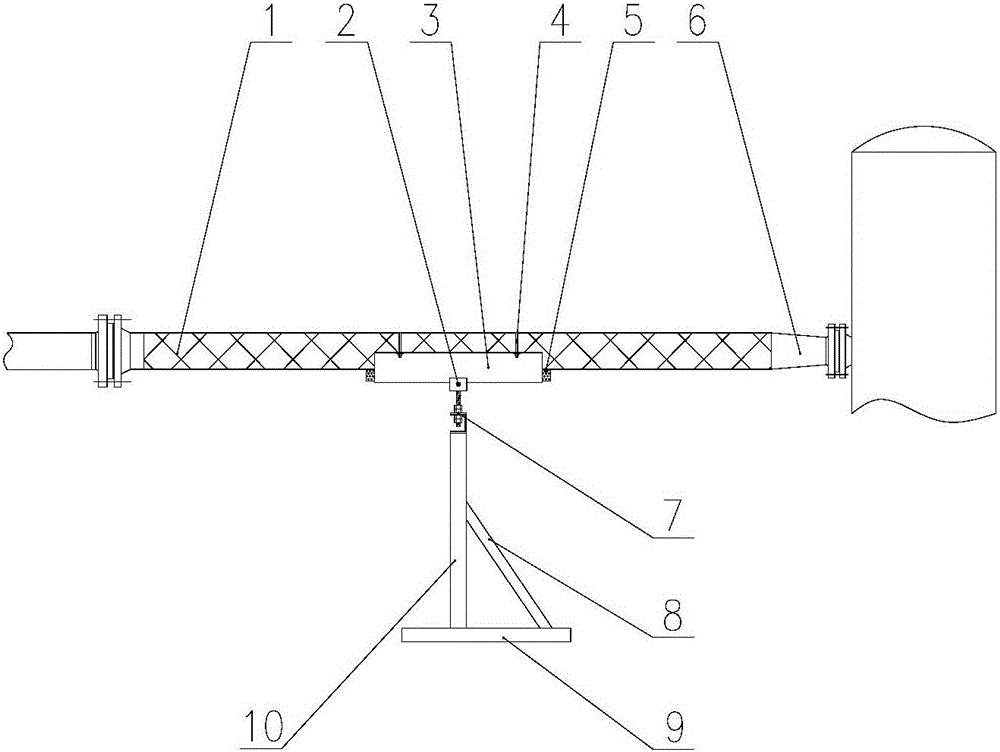

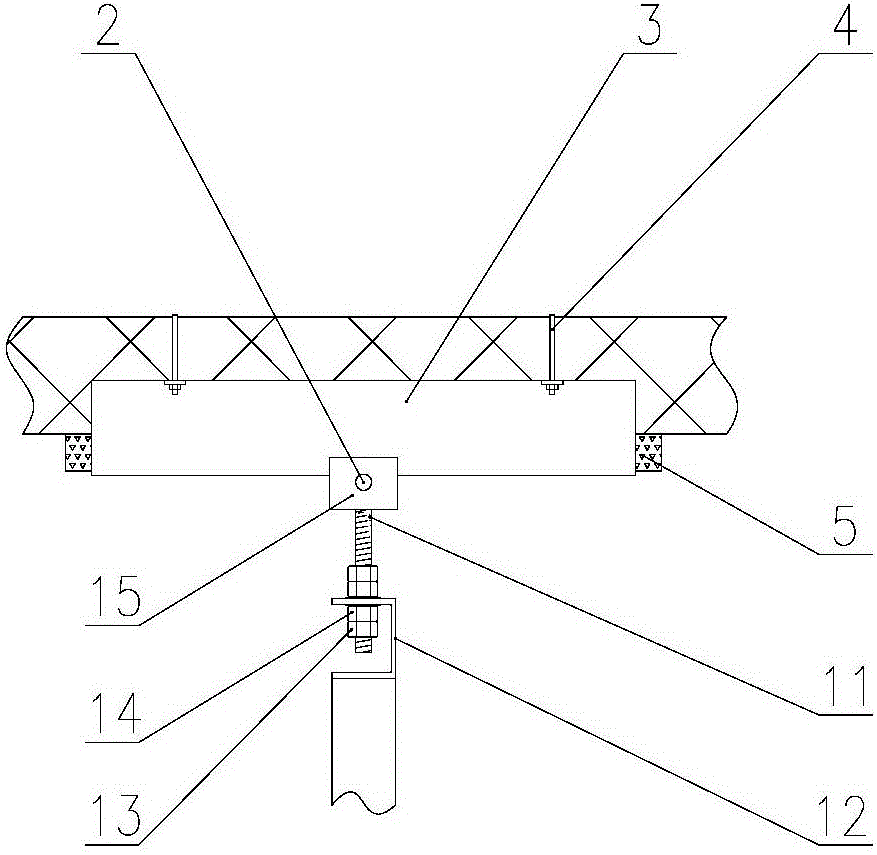

[0018] Below in conjunction with accompanying drawing description and specific implementation, the present invention will be further described:

[0019] Such as figure 1 As shown, the arrow body and the hose are connected by a flange, and the bracket is arranged in the middle of the hose. Such as figure 1 and figure 2 As shown, the present invention consists of a hose 1, a rotating shaft 2, a bracket 3, a hoop 4, a thermal insulation buffer layer 5, an adapter 6, a lifting frame 7, an oblique support 8, a bottom plate 9, a vertical rod 10, an adjusting bolt 11, Base 12, anti-loosening spare nut 13, adjusting nut 14, ear plate 15 are formed. The base plate 9 is fixed to the installation platform by bolts, and the adjusting bolt 11 is fixed on the base 12 by the adjusting nut 14, and a loosening prevention nut 13 is respectively added on both sides. The rotating shaft 2 is welded with the adjusting bolt 11 and passes through the ear plate 15 at the lower part of the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com