Pulse coupling pump

A pulse coupling, pump body technology, applied in pulse balance, pump, pump device and other directions, can solve the problems of unstable measurement accuracy of liquid intake, increase of external volume and manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

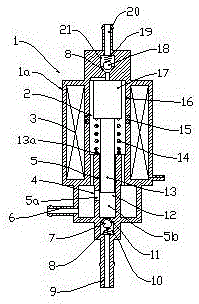

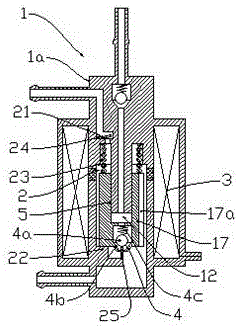

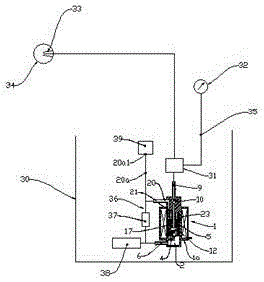

[0019] Such as figure 1 As shown, it is a schematic structural diagram of the first embodiment of the pulse coupling pump provided by the present invention. The pulse coupling pump 1 includes a pump body 1a and a low-pressure pump 2 therein, a high-pressure pump 12, a solenoid 3, a return spring 14, and Liquid channel 6, exhaust channel 20, infusion channel 9.

[0020] The low-pressure pump 2 includes an armature 17 , an armature sleeve 16 and a rectifying valve 21 . The armature 17 is located in the armature sleeve 16 and can move relative to the armature sleeve 16. The armature 17 and the armature sleeve 16 are formed of a magnetically conductive material, and the armature sleeve 16 is embedded with a magnetic gap 15 formed by non-magnetic conduction. , the front end of the armature 17 is located near the magnetic gap 15 . The rectification valve 21 is a ball valve that relies on pressure to open, including a rectification valve member 18, a rectification valve spring 19, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com