Non-woven cloth fixed-width cutting device for non-woven cloth interlayer fence

A non-woven fabric and interlayer technology is applied in the field of non-woven fabric fixed-width cutting equipment for non-woven sandwich fences. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

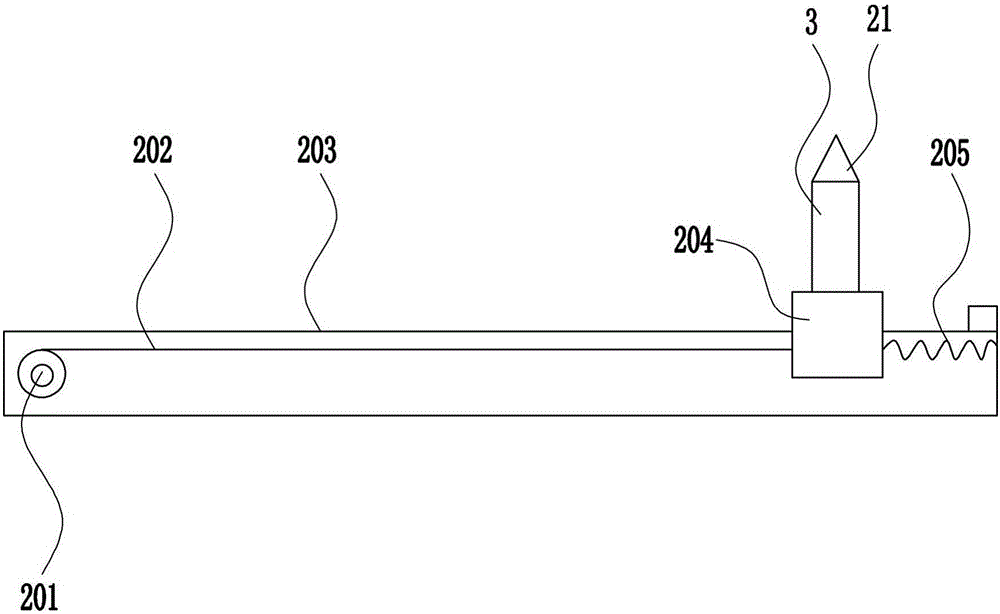

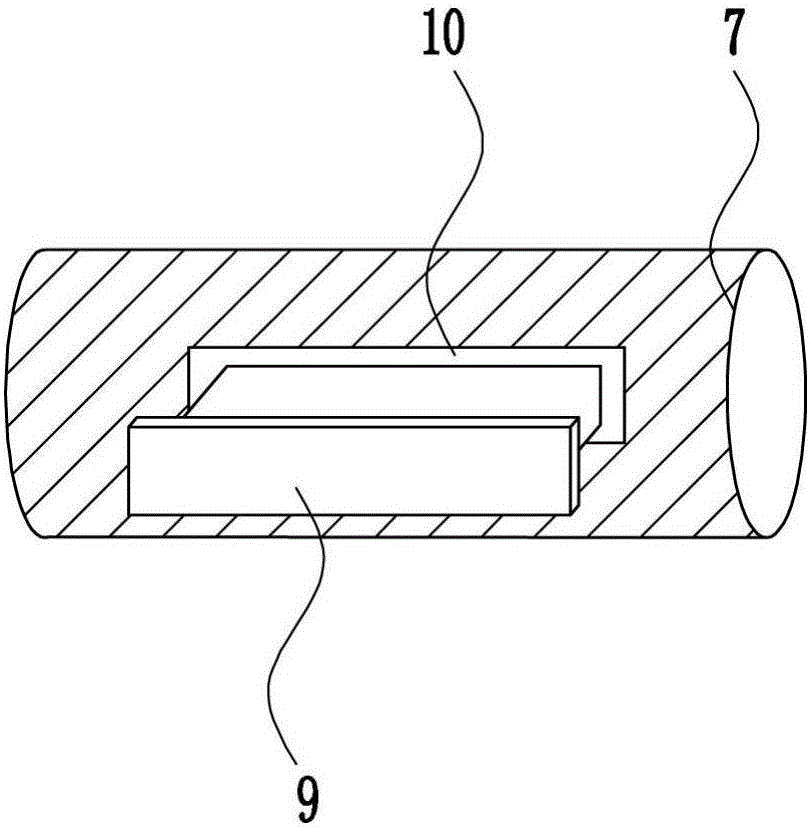

[0032] A non-woven fabric fixed-width cutting device for a non-woven fabric interlayer fence, such as Figure 1-7 As shown, it includes a base plate 1, a front and rear moving device 2, a cutter 3, an indicator plate 4, a cloth winding wheel 5, a cloth 6, a reel 7, a rocker 8, a first rubber block 9, a scale 11, a second slide Rail 14, second slide block 15, fixed plate 16, second rubber block 17, protrusion 18, connecting rod 20 and sharp knife 21, bottom plate 1 top left side rotation type is connected with winding cloth wheel 5, winds on cloth wheel 5 There is a fabric 6, the top right side of the bottom plate 1 is connected with a reel 7 in a rotating manner, and a rocker 8 is welded at an eccentric position on the front side of the reel 7, and a small groove 10 is opened on the top of the reel 7, and a first rubber block is placed in the small groove 10 9. The first rubber block 9 cooperates with the small groove 10. The right part of the base plate 1 is connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com