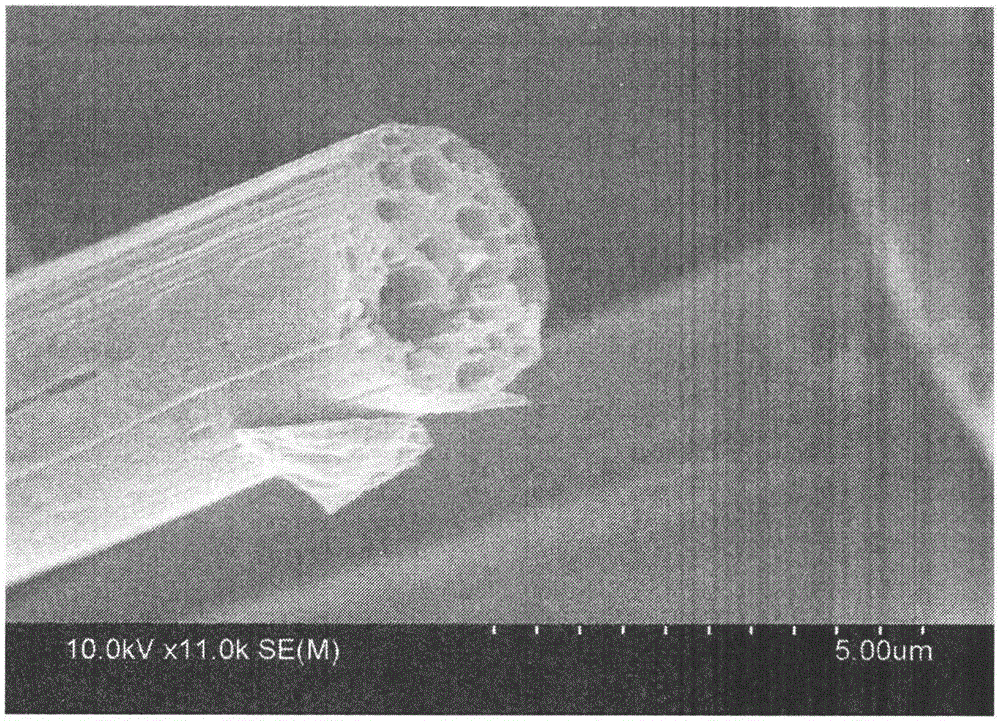

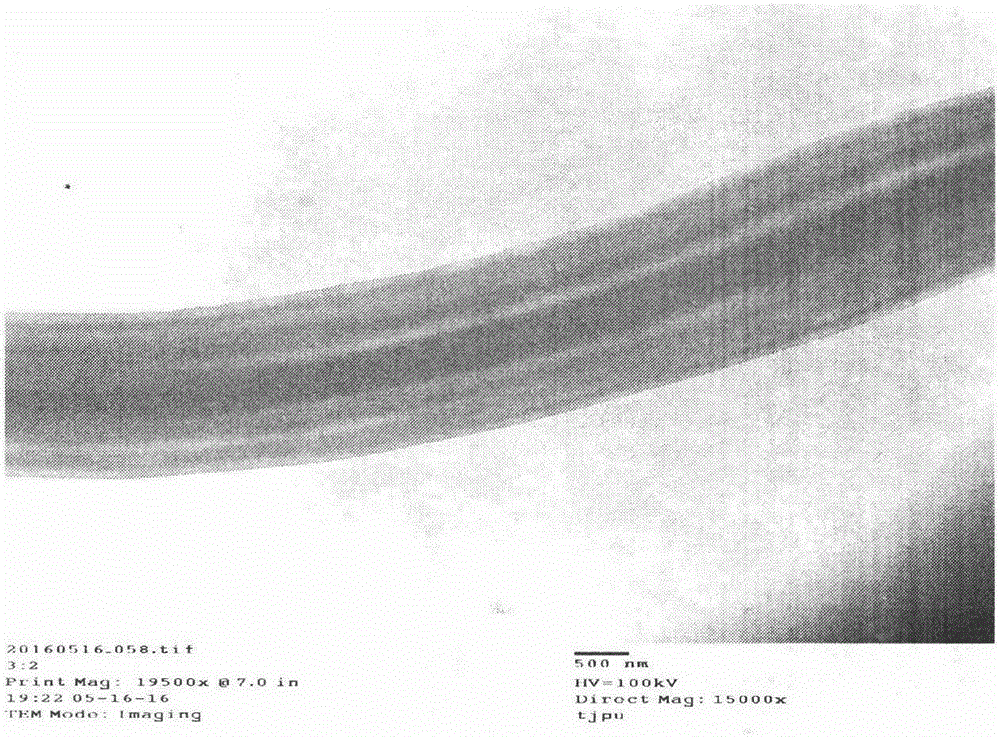

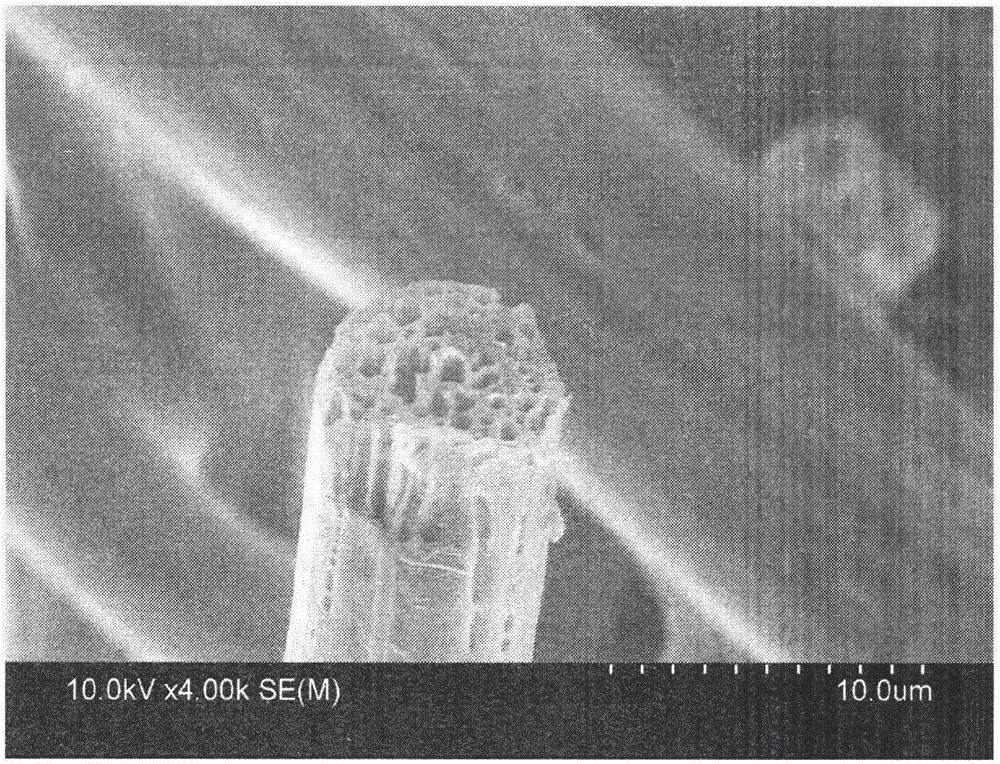

Polyacrylonitrile porous carbon fiber preparation method

A technology of polyacrylonitrile and polystyrene fibers, which is applied in the field of carbon fiber materials, can solve the problems of low electrospinning and spinning efficiency, and achieve the effects of excellent morphology and structure, fast spinning speed and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of PAN / PS solution: Take 1.17g of PS microparticles, add 20g of DMF, stir at 70°C to dissolve completely. Then add 3.5g PAN, stir at room temperature for 12h, at this time, the content of PAN is 15%, and the content of PS is 5%;

[0020] (2) Preparation of PAN / PS nascent fiber by electrostatic melt blowing: add the prepared solution to the syringe pump, the liquid supply rate is 20ml / h, the diameter of the spinning needle tip is 0.8mm, and the positive electrode of the high-voltage power supply is connected to the spinneret needle tip place, the negative electrode is grounded, the voltage of the high-voltage power supply is 35kv, the drafting wind pressure of the spinneret is adjusted to 0.01MPa, and the distance between the receiving device and the spinneret is 50cm;

[0021] (3) Pre-oxidation treatment of PAN / PS as-spun fibers: in the air, the prepared as-spun fibers were heated to 200°C at a heating rate of 2°C / min, kept for 1h, and then naturally coo...

Embodiment 2

[0024] (1) Preparation of PAN / PS solution: Take 1.75g of PS microparticles, add 20g of DMF, stir at 70°C to dissolve completely. Then add 3.5g of PAN, stir at room temperature for 12h, at this time, the content of PAN is 13.8%, and the content of PS is 7%;

[0025] (2) Preparation of PAN / PS nascent fiber by electrostatic melt blowing: add the prepared solution to the syringe pump, the liquid supply rate is 23ml / h, the diameter of the spinning needle tip is 0.8mm, and the positive electrode of the high-voltage power supply is connected to the spinneret needle tip At the place, the negative pole is grounded, the voltage of the high-voltage power supply is 40kv, the drafting wind pressure of the spinneret is adjusted to 0.04MPa, and the distance between the receiving device and the spinneret is 60cm;

[0026] (3) Pre-oxidation treatment of PAN / PS as-spun fibers: in the air, the prepared as-spun fibers were heated up to 260°C at a heating rate of 2°C / min, kept for 1h, and then n...

Embodiment 3

[0029] (1) Preparation of PAN / PS solution: take 2.33g PS microparticles, add 20g DMF, stir at 70°C to dissolve completely. Then add 3.5g PAN, stir at room temperature for 12h, at this time, the content of PAN is 13.6%, and the content of PS is 9%;

[0030] (2) Preparation of PAN / PS nascent fiber by electrostatic melt blowing: add the prepared solution to the syringe pump, the liquid supply rate is 27ml / h, the diameter of the spinning needle tip is 0.8mm, and the positive pole of the high-voltage power supply is connected to the spinneret needle tip At the place, the negative electrode is grounded, the voltage of the high-voltage power supply is 40kv, the drafting wind pressure of the spinneret is adjusted to 0.07MPa, and the distance between the receiving device and the spinneret is 70cm;

[0031] (3) Pre-oxidation treatment of PAN / PS as-spun fibers: in the air, the prepared as-spun fibers were heated up to 260°C at a heating rate of 2°C / min, kept for 1h, and then naturally co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com