Manufacturing method of high-strength non-oriented silicon steel for new energy vehicle driving motor

A new energy vehicle and drive motor technology, applied in the field of electrical steel manufacturing, can solve problems such as difficult processing and difficult to meet performance requirements, achieve good magnetic properties, improve mechanical strength and toughness, and control the effects of precipitate characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

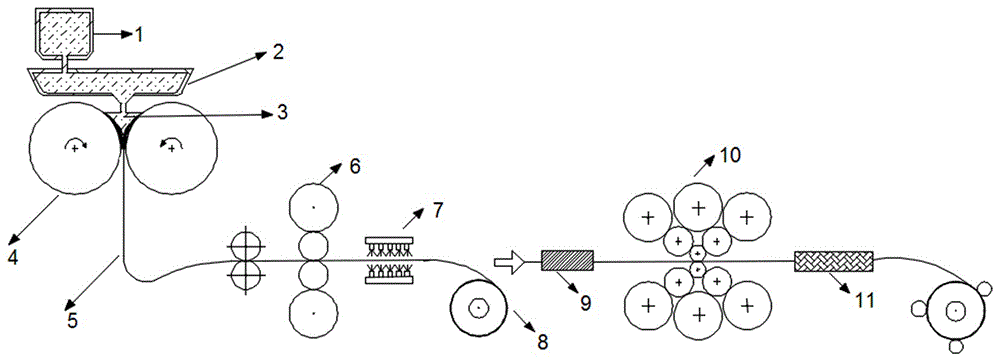

Method used

Image

Examples

Embodiment 1

[0042] The molten steel smelted in a vacuum induction furnace contains 0.002% by weight of C, 2.8% of Si, 0.2% of Mn, 2% of Al, 0.5% of Ni, 0.5% of Cr, 0.08% of Nb, 0.003% of O, 0.004% of S, N 0.004%, P 0.005%, the balance is Fe and inevitable inclusions; where Nb / 93-(C / 12+N / 14)=0.08 / 93-(0.002 / 12+0.004 / 14)=0.00086-(0.00017 +0.00029)=0.0004;

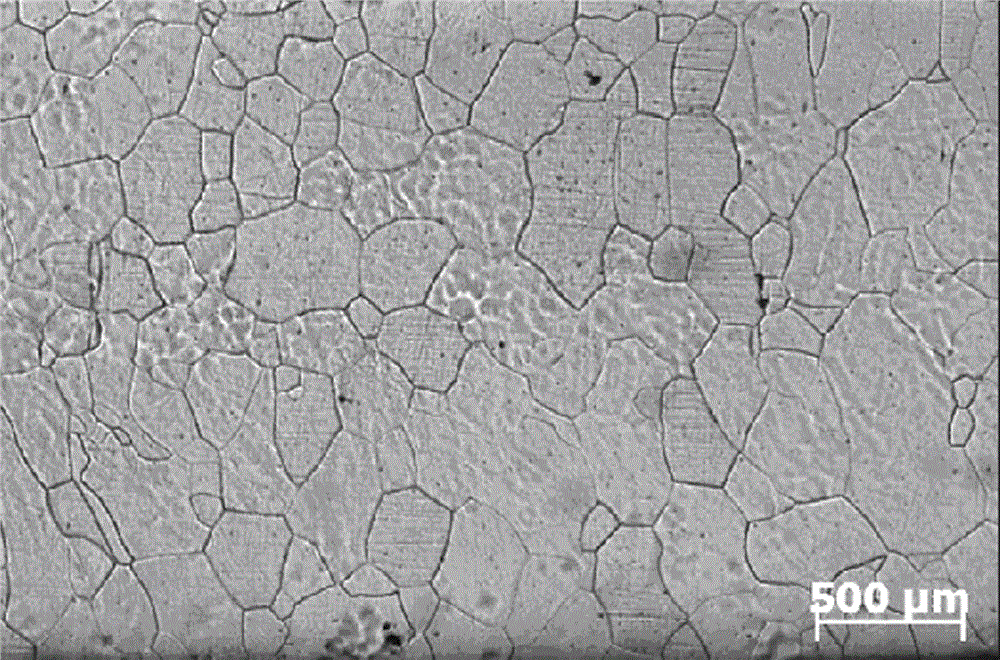

[0043] The molten steel is introduced into the tundish and poured into the twin-roll strip continuous casting equipment for continuous casting through the distribution nozzle. Obtain a cast strip with a thickness of 2.7mm; the metallographic structure is as figure 2 shown;

[0044] The cast strip is air-cooled to 1100°C and then hot-rolled on-line. The hot-rolling start temperature is 1100°C, the final rolling temperature is 900°C, and the reduction is 26%.

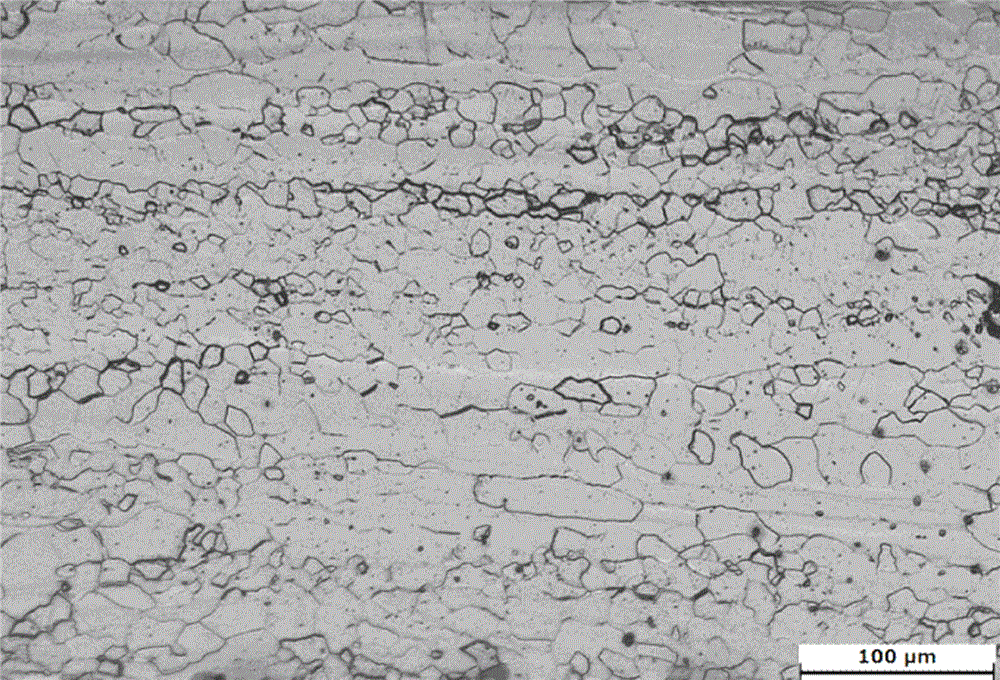

[0045] The hot-rolled sheet is pickled to remove surface oxide scale, and then cold-rolled for 6 passes to obtain a cold-rolled sheet with a thickness of 0.35 mm;

[0046] The c...

Embodiment 2

[0049] Molten steel smelted in a vacuum induction furnace, its composition contains C 0.003%, Si 3.1%, Mn 1.0%, Al 1.2%, Ni 1.5%, Cr 2.0%, Nb 0.12%, O 0.003%, S 0.004% by weight percentage, N 0.002%, P 0.005%, the balance is Fe and inevitable inclusions; where Nb / 93-(C / 12+N / 14)=0.12 / 93-(0.003 / 12+0.002 / 14)=0.0013-( 0.00025+0.00014)=0.0009;

[0050] The molten steel is introduced into the tundish and poured into the twin-roll thin strip continuous casting equipment for continuous casting through the distribution nozzle. Obtain a cast strip with a thickness of 2.6mm;

[0051] The cast strip is air-cooled to 1120°C and then hot-rolled online. The hot-rolling start temperature is 1120°C, the final rolling temperature is 930°C, and the reduction is 35%.

[0052] The hot-rolled sheet is pickled to remove surface oxide scale, and then cold-rolled for 5 passes to obtain a cold-rolled sheet with a thickness of 0.35mm;

[0053] The cold-rolled sheet is annealed, and the annealing trea...

Embodiment 3

[0056] Molten steel smelted in a vacuum induction furnace, its composition contains C 0.004%, Si 3.5%, Mn 0.5%, Al 0.5%, Ni 1.0%, Cr 3%, Nb 0.15%, O 0.003%, S 0.004% by weight percentage, N 0.003%, P 0.005%, the balance is Fe and inevitable inclusions; where Nb / 93-(C / 12+N / 14)=0.15 / 93-(0.004 / 12+0.003 / 14)=0.0016-( 0.00033+0.00021)=0.0011;

[0057] The molten steel is introduced into the tundish and poured into the twin-roll strip continuous casting equipment for continuous casting through the distribution nozzle. Obtain a cast strip with a thickness of 2.5mm;

[0058] The cast strip is air-cooled to 1140°C and then hot-rolled on-line. The hot-rolling start temperature is 1140°C, the final rolling temperature is 980°C, and the reduction is 28%.

[0059] The hot-rolled sheet is pickled to remove surface oxide scale, and then cold-rolled for 4 passes to obtain a cold-rolled sheet with a thickness of 0.35mm;

[0060] The cold-rolled sheet is annealed, and the annealing treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com