Production method and application of fermented fructus crataegi flavor

The technology of spice and hawthorn is applied in the field of preparation of fermented hawthorn spice to achieve the effects of high product yield, improved quality and reduced irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

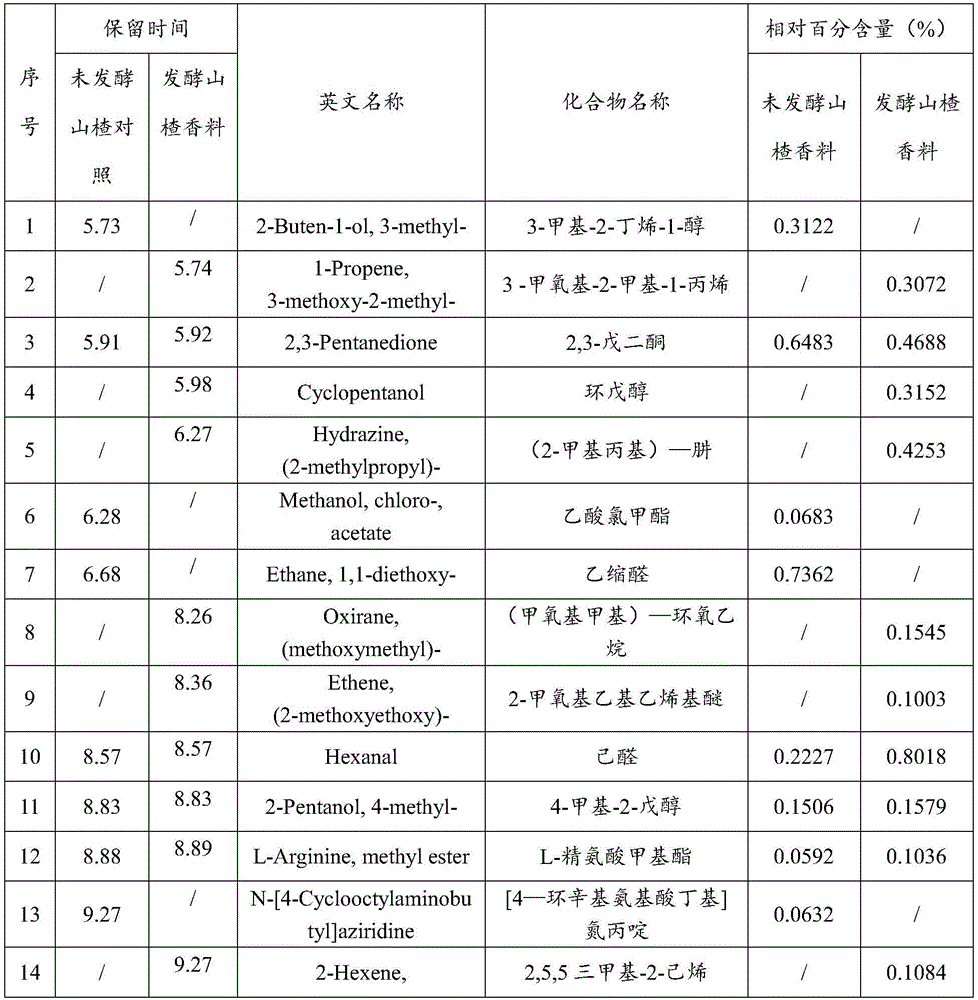

Image

Examples

Embodiment 1

[0034] A preparation method of fermented hawthorn spice, comprising the steps of:

[0035] 1) Mix hawthorn powder and water at a mass ratio of 1:20, extract at 60°C for 3 hours, filter with suction, repeat extraction of the filter residue twice, combine the filtrate, and sterilize;

[0036] 2) Strain activation: Bacillus methanolate VJ4-1 was activated and cultured to obtain Bacillus methanolate activation liquid; the strain activation conditions were: 25°C, pH 4.5, 100r / min shaking culture for 24 hours;

[0037] 3) Fermentation: Inoculate the activated bacterium liquid obtained in step 2) into the hawthorn combined filtrate in the above-mentioned step 1) by volume ratio 5% to form a fermented liquid. The canned amount of the above-mentioned fermented liquid is 20%. The culture conditions are the same as the activation culture conditions; the culture time is 2 days;

[0038] 4) The fermented liquid obtained in step 3) is concentrated under reduced pressure to a relative densi...

Embodiment 2

[0042] A preparation method of fermented hawthorn spice, comprising the steps of:

[0043] 1) Mix hawthorn powder and water at a mass ratio of 1:15, extract at 65°C for 4 hours, filter with suction, repeat extraction of the filter residue 3 times, combine the filtrate, and sterilize;

[0044] 2) Strain activation: Bacillus methanolate VJ4-1 was activated and cultured to obtain Bacillus methanolate activation solution; the strain activation conditions were: 30°C, pH5, 110r / min shaking culture for 48 hours;

[0045] 3) Fermentation: Inoculate 10% of the activated bacterial liquid obtained in step 2) into the hawthorn combined filtrate in the above step 1) by volume to form a fermented liquid. The canned amount of the above-mentioned fermented liquid is 30%. The culture conditions are the same as the activation culture conditions; the culture time is 3 days;

[0046] 4) The fermented liquid obtained in step 3) is concentrated under reduced pressure to a relative density of 1.2-1...

Embodiment 3

[0049] A preparation method of fermented hawthorn spice, comprising the steps of:

[0050] 1) Mix hawthorn powder and water at a mass ratio of 1:40, extract at 70°C for 5 hours, filter with suction, repeat extraction of the filter residue 3 times, combine the filtrate, and sterilize;

[0051] 2) Strain activation: Bacillus methanolate VJ4-1 was activated and cultured to obtain the Bacillus methanolate activation solution; the strain activation conditions were: 35°C, pH 6, 130r / min shaking culture for 72 hours;

[0052] 3) Fermentation: Inoculate 20% of the activated bacterial liquid obtained in step 2) into the hawthorn combined filtrate in the above-mentioned step 1) by volume to form a fermented liquid. The canned amount of the above-mentioned fermented liquid is 40%. The culture conditions are the same as the activation culture conditions; the culture time is 5 days;

[0053] 4) The fermented liquid obtained in step 3) is concentrated under reduced pressure to a relative d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com