Black dye composition and dyeing application and method thereof on fibers

A dye composition, dye compound technology, applied in the direction of dyeing, organic dyes, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

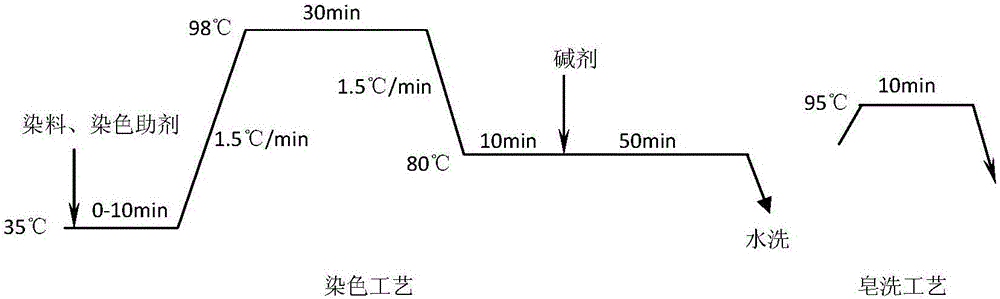

Method used

Image

Examples

Embodiment 1

[0110] Lift rate test (K / S value at absorption wavelength 600nm)

[0111] Measure the promotion rate of following dyestuff according to above-mentioned embodiment measuring method, test result is recorded in table 2

[0112] Table 2

[0113]

[0114] It can be seen from Table 2:

[0115] The black dye composition of the present invention has good lifting performance, and a satisfactory dyeing depth can be achieved by using a small amount; at the same time, the dyeing depth of viscose and nylon fibers is close, and the synchronous lifting performance is good.

Embodiment 2

[0117] Dye exhaustion rate and color fixation rate test (absorption wavelength 600nm)

[0118] Determination of exhaustion rate and color fixation rate of following dyestuffs according to above-mentioned embodiment measuring method, test result is recorded in table 3

[0119] table 3

[0120] dye Exhaustion rate (%) Fixation rate (%) Dye Composition A 88.4 82.7 Dye composition B 90.2 83.9 Dye composition C 89.5 83.0 Dye composition D 88.1 81.8

[0121] It can be seen from Table 3:

[0122] The black dye composition of the present invention has higher dyeing exhaustion rate and color fixing rate, and the color fixing rate and the dyeing exhaustion rate are relatively close. This shows that the dye utilization rate is very high, the floating color is easy to remove, the actual production washing process is reduced, and the discharge of dyeing sewage in production can be greatly reduced.

Embodiment 3

[0124] Same color test

[0125] Measure the homochromaticity of following dyestuff according to above-mentioned embodiment measuring method, test result is recorded in table 4

[0126] Table 4

[0127]

[0128]

[0129] It can be seen from Table 4:

[0130] Compared with reference dye X and reference dye Y, the black dye composition of the present invention has similar apparent depth on both surfaces of nylon and viscose, and smaller color difference value. Excellent homochromaticity when dyeing brocade and viscose roman cloth, and can achieve excellent level dyeing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com