Integrated sewage purifying system for aquaculture and purifying method

A technology for sewage purification and aquaculture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

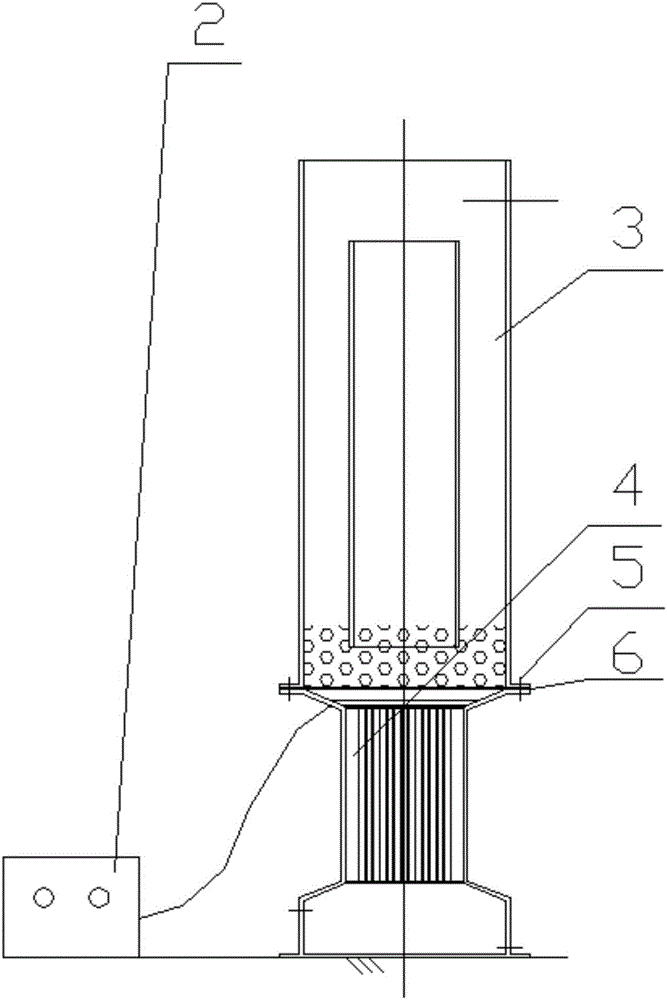

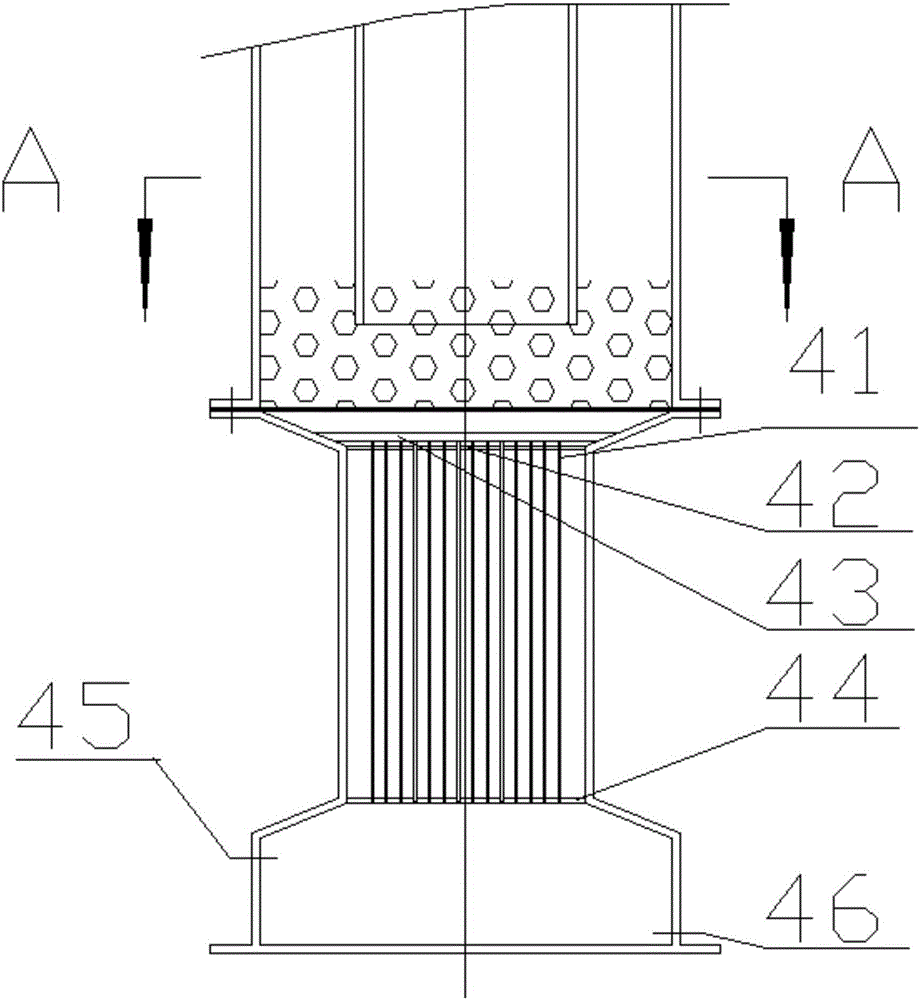

[0028] see Figure 1-5 , an integrated sewage purification system for fish farming, including the following content: it is composed of an integrated device body, an electric control box 2, and the like. The body of the integrated device is divided into two layers, the upper layer is a three-phase internal circulating fluidized bed 3, and the lower layer is an electrolytic coagulation purification unit 4. The upper and lower layers are connected by bolts 5, and a sealing ring 6 is provided between the layers.

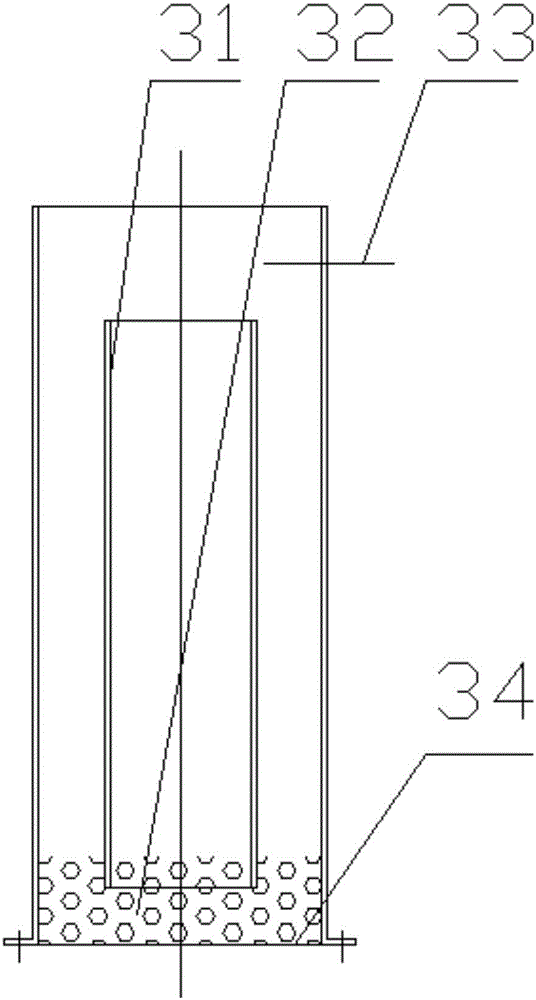

[0029] 1) Three-phase internal circulating fluidized bed: the fluidized bed cavity has a built-in diversion cylinder 31, which is fixedly connected to the fluidized bed cavity, the ratio of the diameter of the diversion cylinder 31 to the cavity diameter is 0.5, and the length of the diversion cylinder The ratio to the diameter of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com