Flowerlike alpha-FeOOH porous micro-nanospheres and preparation method thereof

A technology of micro-nano balls and flower-shaped balls, which is applied in the field of nanomaterials, can solve the problems of low specific surface area and inability to catalyze degradation applications, and achieve the effects of high specific surface area, easy control of product composition, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of flower-like α-FeOOH porous micro-nanosphere comprises the steps:

[0028] (1) Prepare light yellow solution a with 50ml of deionized water and 50ml of N,N-dimethylformamide (DMF), pH 4.5.

[0029] (2), then weigh the Fe of 0.014g 2 SO 4 ·7H 2 O was dissolved in solution a, and a deep yellow solution b with a volume of 100 ml was obtained after stirring for 1 minute and ultrasonic dispersion.

[0030] (3) Put solution b into a constant temperature drying oven, and heat-treat at 40° C. for 5 hours to obtain solution c and precipitate d.

[0031] (4) The precipitate d was collected by centrifugation, ultrasonically cleaned with deionized water and absolute ethanol, and finally dried to obtain the brown target product, namely flower-shaped α-FeOOH porous micro-nanospheres.

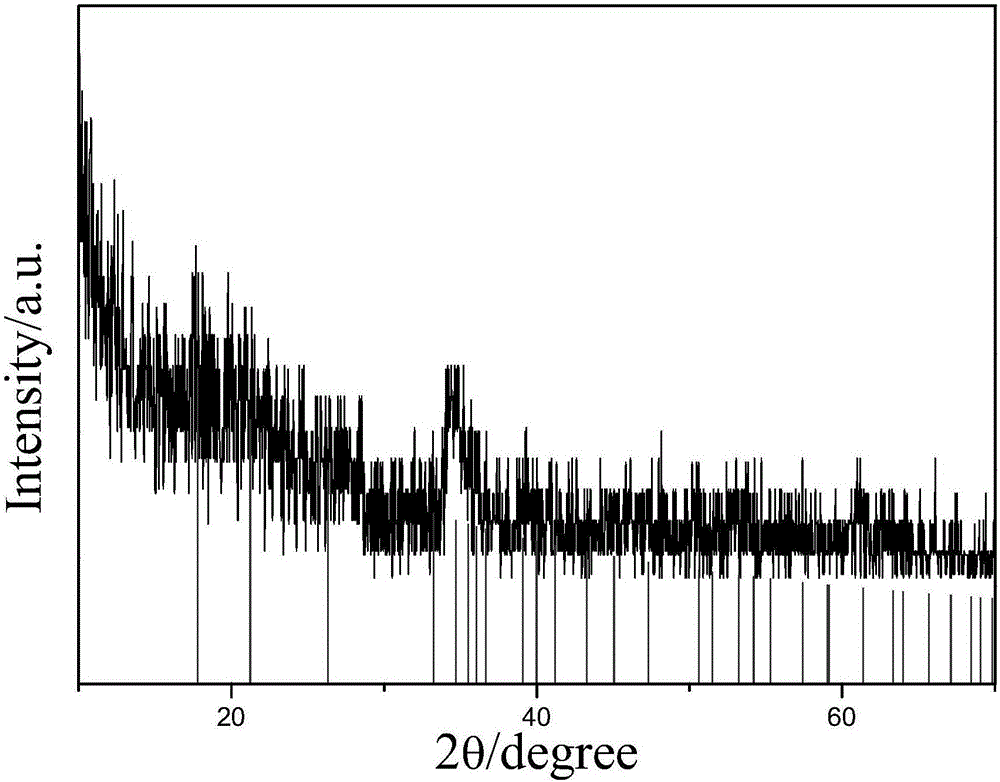

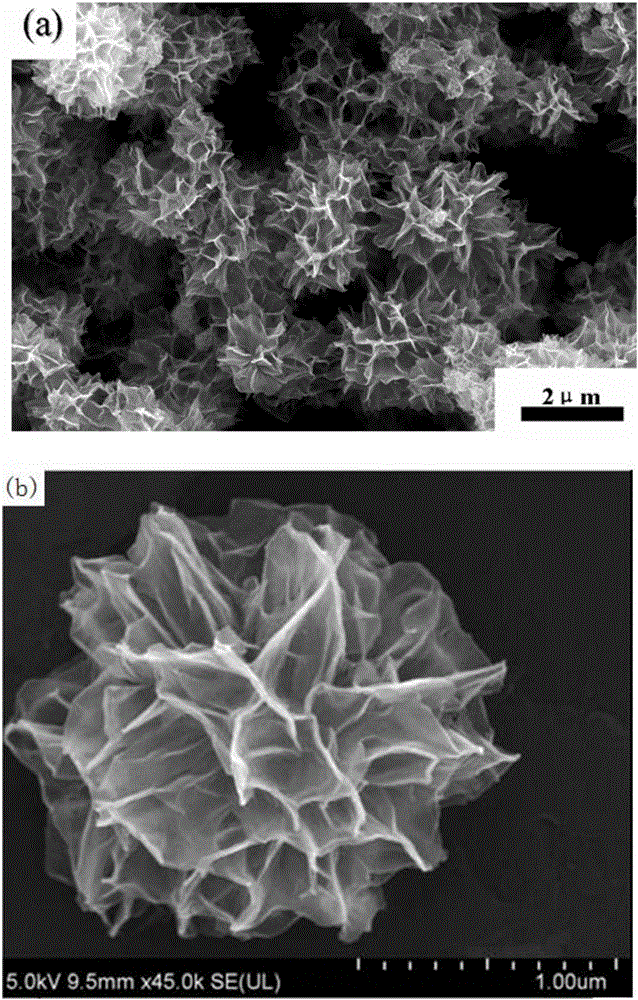

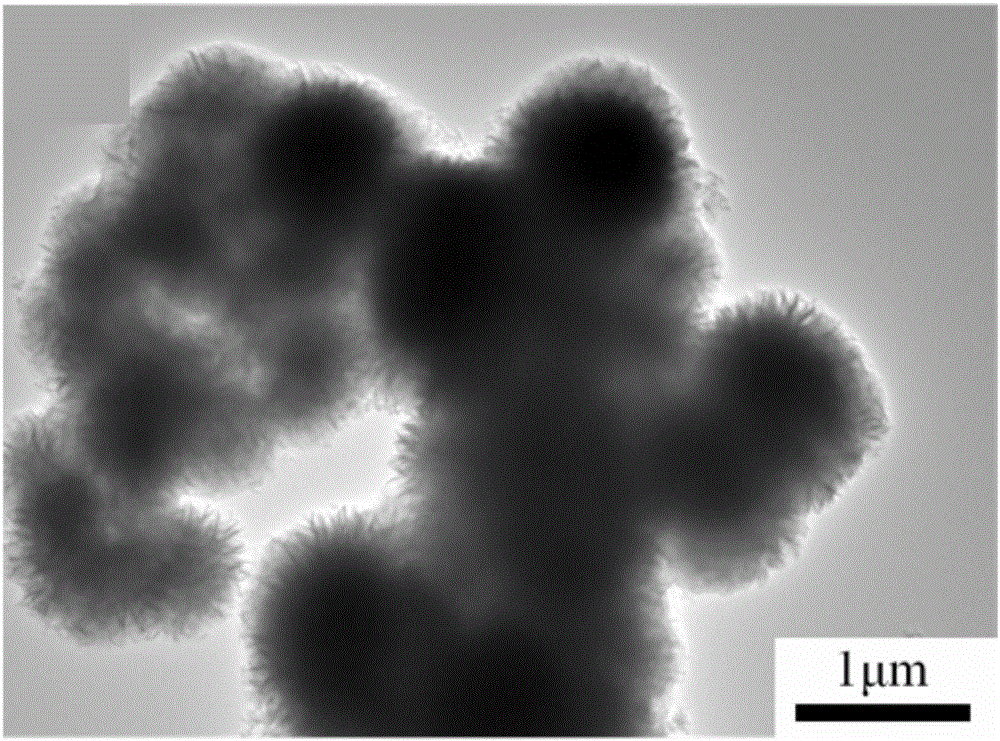

[0032] figure 1 It is the XRD spectrum pattern of the product obtained in Example 1. Compared with the standard α-FeOOH spectrum (JCPDS: 29-0713), the obtained product is...

Embodiment 2

[0036] The preparation method of flower-like α-FeOOH porous micro-nanosphere comprises the steps:

[0037] (1) Prepare light yellow solution a with 40ml of deionized water and 60ml of N,N-dimethylformamide (DMF), pH 4-5.

[0038] (2), then weigh 0.010g of Fe 2 SO 4 ·7H 2 O was dissolved in solution a, and a dark yellow solution b with a volume of 100 ml was obtained after 3 minutes of stirring and ultrasonic dispersion.

[0039] (3) Put solution b into a constant temperature drying oven, and heat-treat at 35° C. for 6 hours to obtain solution c and precipitate d.

[0040] (4) The precipitate d was collected by centrifugation, ultrasonically cleaned with deionized water and absolute ethanol, and finally dried to obtain the brown target product, namely flower-shaped α-FeOOH porous micro-nanospheres.

Embodiment 3

[0042] The preparation method of flower-like α-FeOOH porous micro-nanosphere comprises the steps:

[0043] (1) Prepare light yellow solution a with 55ml of deionized water and 45ml of N,N-dimethylformamide (DMF), pH 4-5.

[0044] (2), then weigh 0.020g of Fe 2 SO 4 ·7H 2 O was dissolved in solution a, and a deep yellow solution b with a volume of 100 ml was obtained after 5 minutes of stirring mixing and ultrasonic dispersion.

[0045] (3) Put solution b into a constant temperature drying oven, and heat-treat at 45° C. for 4 hours to obtain solution c and precipitate d.

[0046] (4) The precipitate d was collected by centrifugation, ultrasonically cleaned with deionized water and absolute ethanol, and finally dried to obtain the brown target product, namely flower-shaped α-FeOOH porous micro-nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com