Electric power overhaul working platform and system thereof

A technology for power maintenance and working platform, applied in the direction of lifting device, etc., can solve the problems of low work efficiency and poor safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

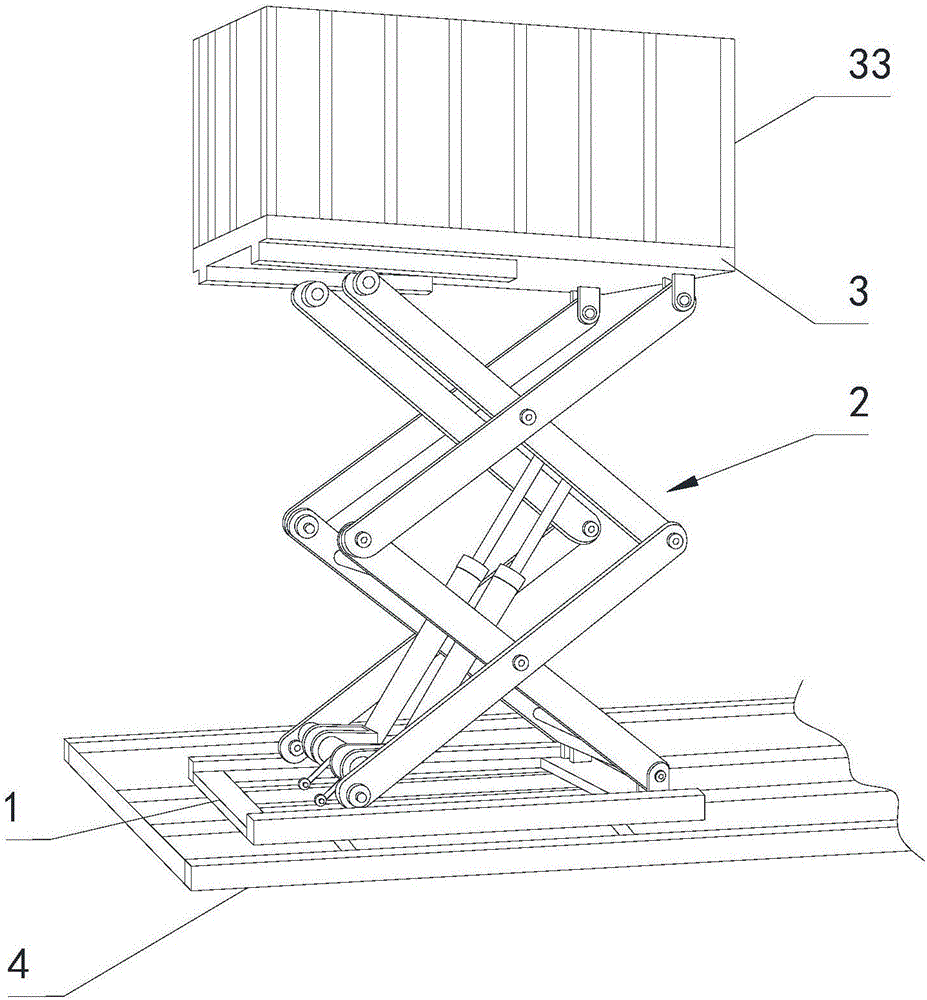

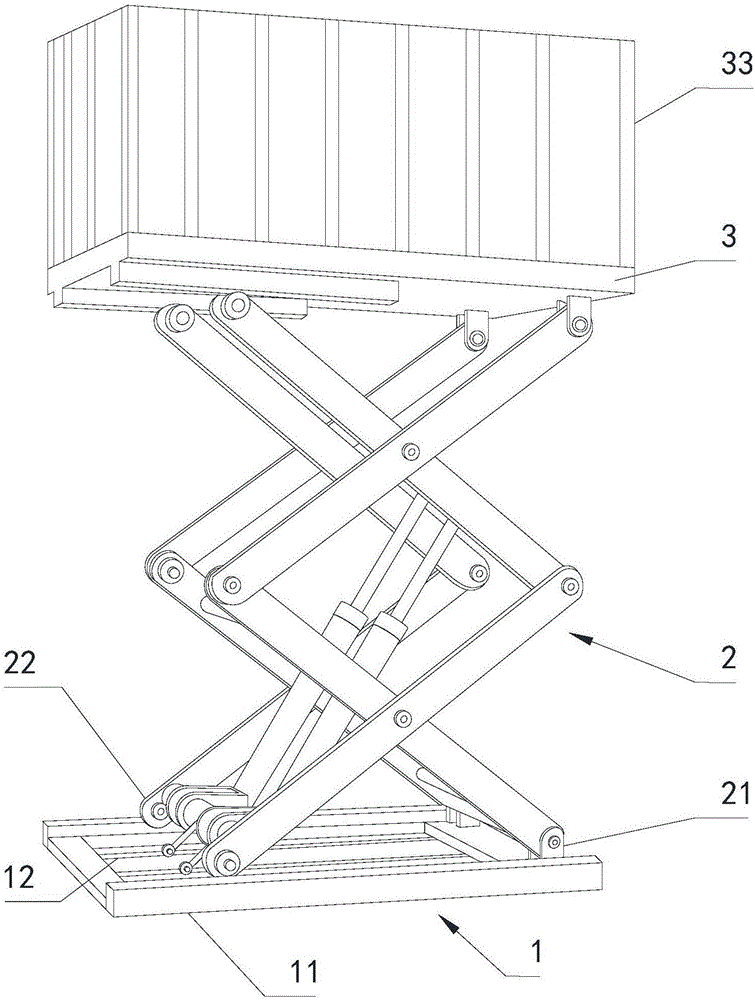

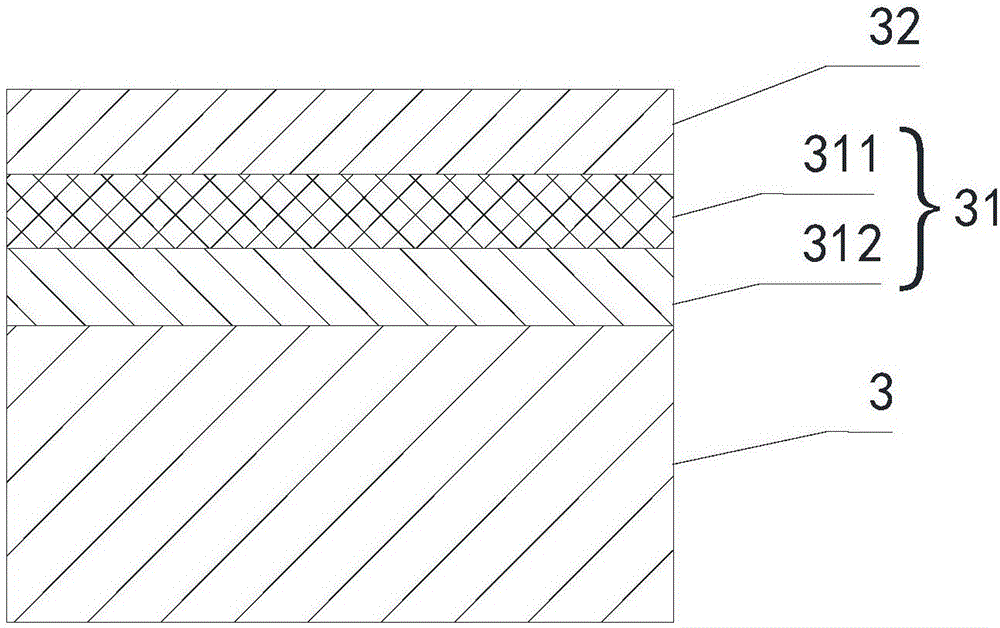

[0044] see Figure 1-Figure 4 As shown, the present embodiment provides a power maintenance work platform; figure 1 , figure 2 Schematic diagram of the structure of the power maintenance work platform provided in this embodiment, wherein, figure 2 The dock is not shown; image 3 A schematic cross-sectional view of the workbench of the power maintenance work platform provided in this embodiment; Figure 4 A schematic diagram of circuit connection of the electric power maintenance work platform provided in this embodiment.

[0045] see Figure 1-Figure 4 As shown, the power maintenance work platform provided by this embodiment includes a base 1 , a scissor lift frame 2 and a workbench 3 ; the top of the scissor lift frame 2 is connected to the bottom of the workbench 3 .

[0046] The base 1 is connected with a vertical driving device 110 for driving the vertical lift of the workbench 3; direction extension.

[0047] The bottom of the scissor lift bracket 2 includes a sc...

Embodiment 2

[0078] Embodiment 2 provides a power maintenance work system, which includes the power maintenance work platform described in Embodiment 1. The technical features of the power maintenance work platform disclosed in Embodiment 1 are also applicable to this embodiment. Embodiment 1 The technical features of the disclosed electric maintenance work platform will not be described repeatedly.

[0079] The power maintenance work system provided in this embodiment includes a power maintenance work platform, and also includes a work box and maintenance tools; the work box is arranged on the table top of the workbench, and the maintenance tools are placed in the work box.

[0080] The electric power maintenance working system in this embodiment has the advantages of the electric power maintenance work platform described in the first embodiment, and the advantages of the electric power maintenance work platform disclosed in the first embodiment will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com