Tower crane, pipeline and building self-elevating construction method and device

A construction method and building technology, applied in the direction of hoisting devices, etc., can solve the problems of impossible to reach hoisting machinery, long construction period, and objects that cannot be hoisted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

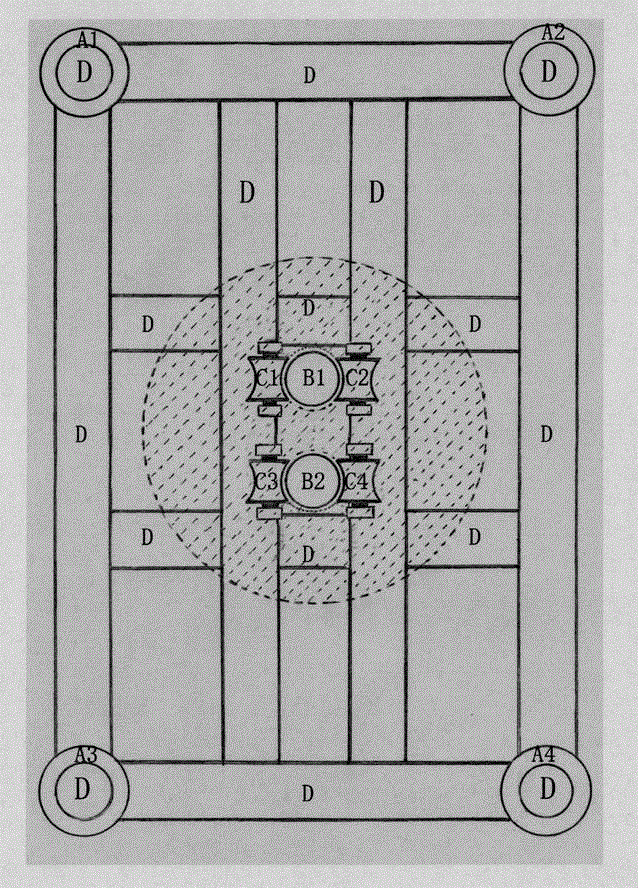

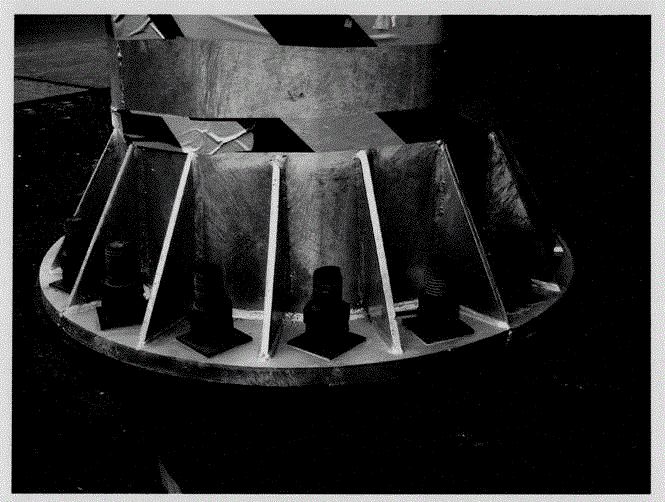

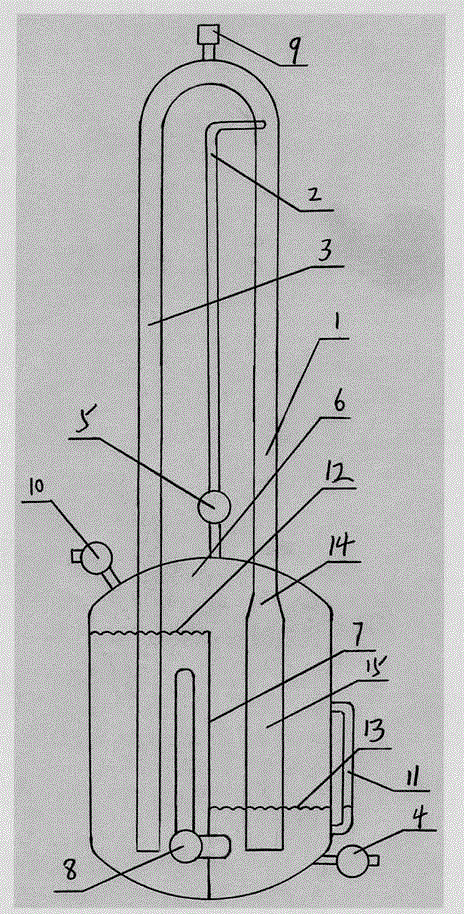

[0014] Picture 1-1 It is a plan view of the hoisting platform of the present invention. The structure diagram of the hoisting platform is used for the hoisting of the n-shaped tube of the gravity energy equipment in the artificial environment. Because the n-shaped tube is composed of two standpipes, it is designed as a double-tube limit roller. The rollers of the ground lifting platform, the first-floor platform, and the second-floor platform jointly form a limit roller group, which effectively ensures the upward direction of the pipeline. It is also possible for two-layer platforms to form a limit roller group. Figure 1-2 It is the connection diagram of the reserved flange of the underground foundation and the column of the self-lifting platform of the present invention. Figure 1-3 It is a reference structure diagram for the application of the present invention to gravity power generation self-lifting construction in artificial environment. Figure 1-4 It is a schematic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com