An automatic sample preparation system for sample collection and preparation

An automatic sample preparation and sample technology, which is applied in the direction of transportation, packaging, conveyors, etc., can solve the problems affecting the accuracy of analysis and testing, high labor intensity, sample preparation pollution, etc., to ensure the accuracy of analysis and testing, reduce labor intensity, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

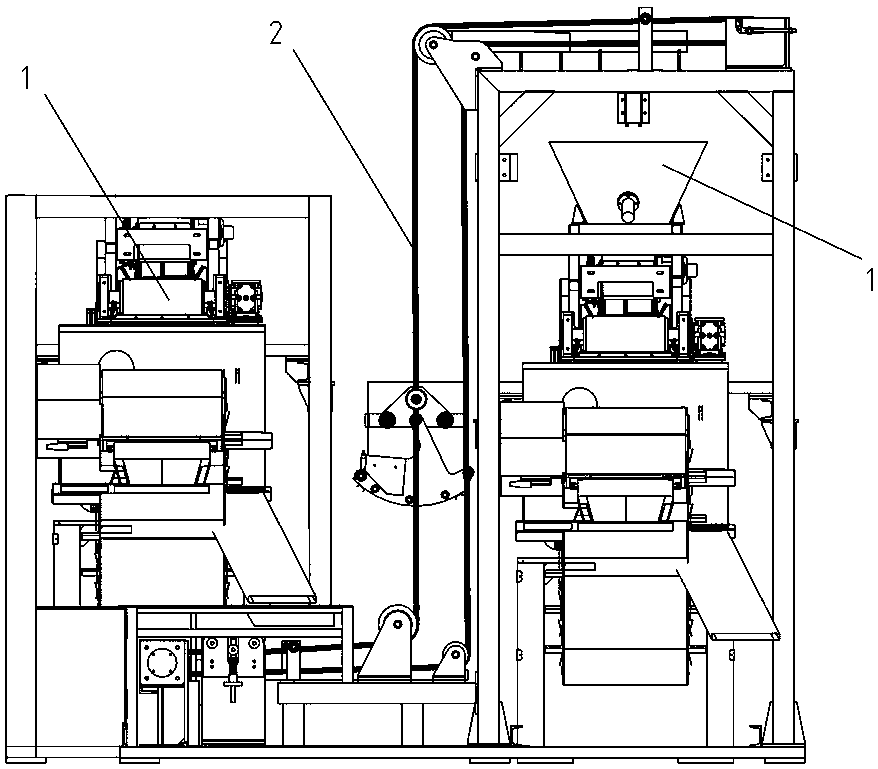

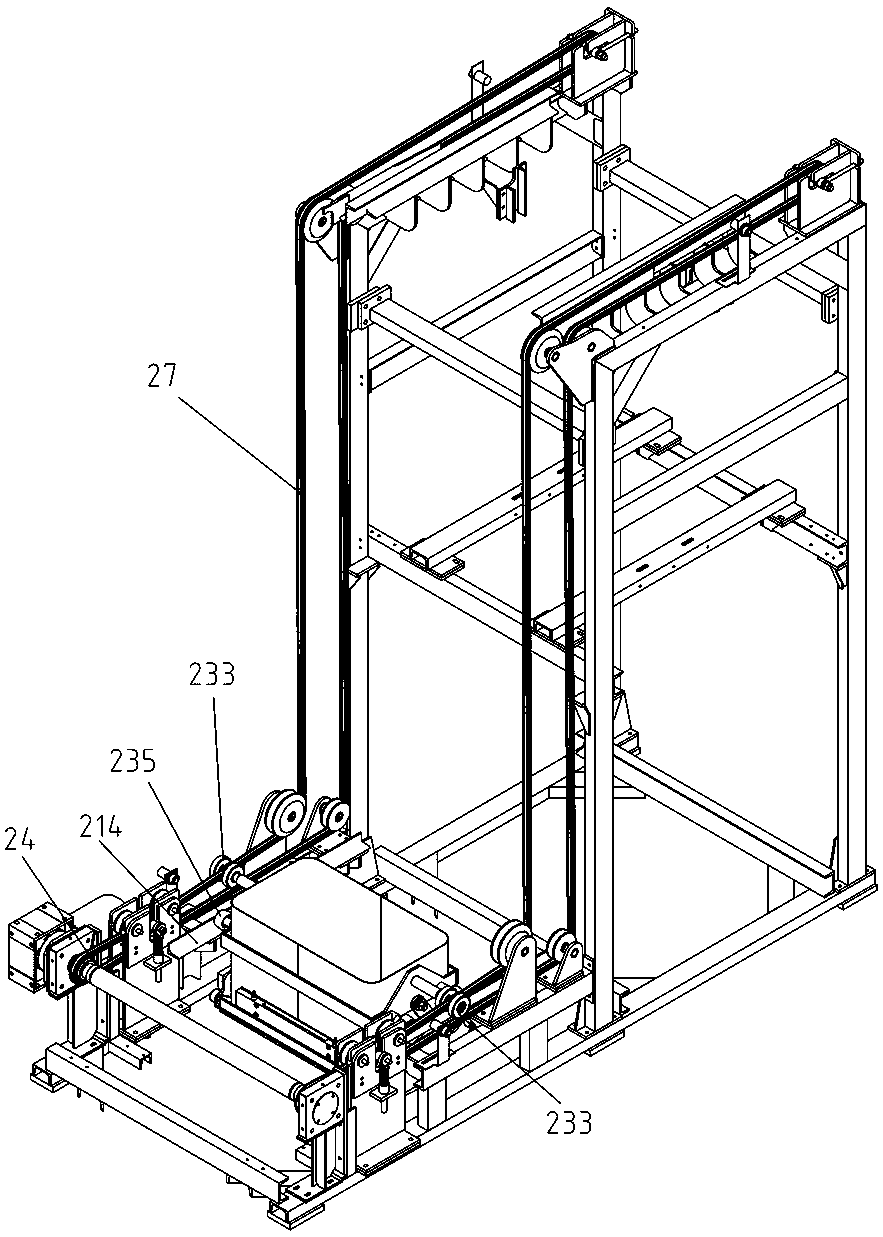

[0043] Such as Figure 1 to Figure 10 As shown, the present invention provides an automatic sample preparation system for sample collection and processing, including more than two sample preparation processing units 1, and a Z for upwardly lifting and transporting materials is provided between two adjacent sample preparation processing units 1. Z-type conveying device 2, Z-type conveying device 2 comprises frame 21 and the driving assembly 22 that is arranged on the frame 21, material carrying barrel 23 and two symmetrically arranged Z-shaped chain conveying passages, each Z-shaped chain conveying passage Comprising a matching driving wheel assembly 24, a driven wheel assembly 25, a guide wheel assembly 26 and an endless chain 27, the two ends of the transport bucket 23 are respectively connected to two endless chains 27, and the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com