Full-automatic detonator tube end-capping, labeling and winding machine

A detonating tube and fully automatic technology, which is applied in the field of fully automatic detonating tube sealing and labeling handle machines, can solve the problems of production efficiency and production stability, and achieve safe and stable operation, saving waste, The effect of improving the tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

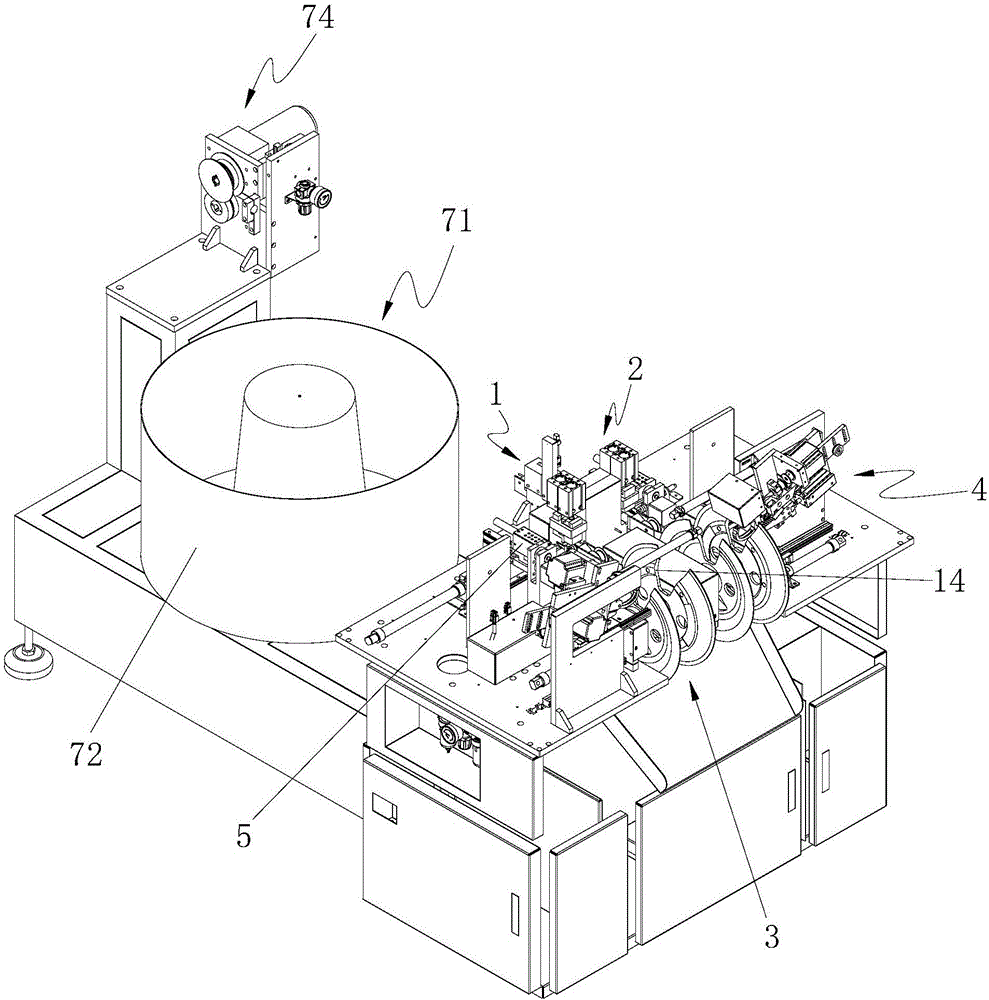

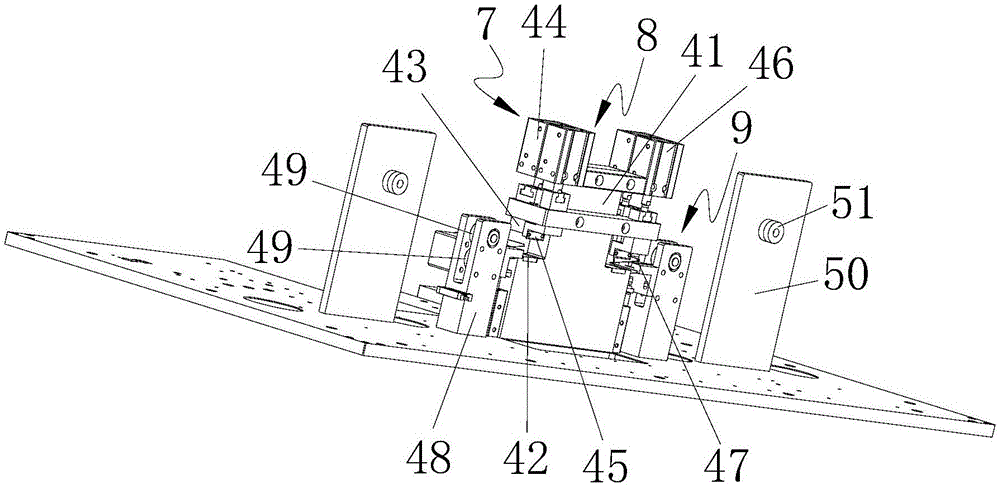

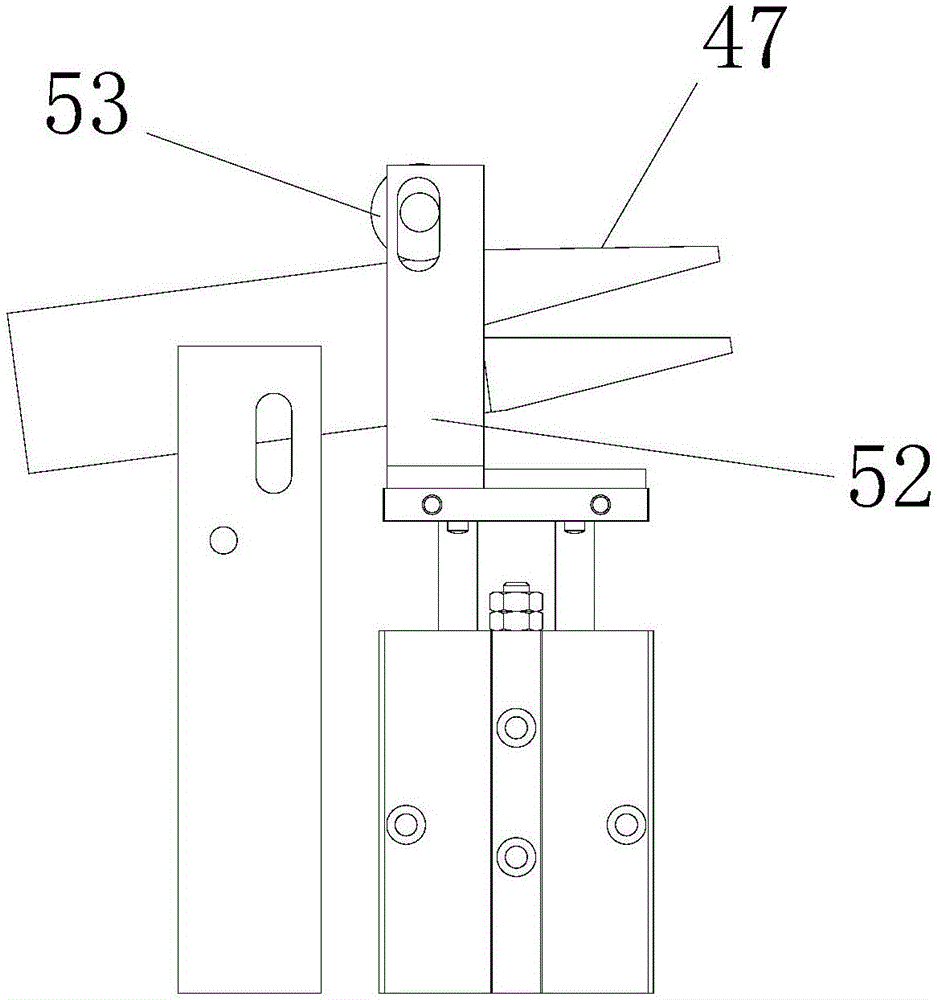

[0047] A detonating tube automatic tail sealing and labeling handle machine, comprising a detonating tube feeding mechanism 1, a label feeding and cutting device 2, a tube winding and winding turntable device 3, a wire binding mechanism 4, and a device for heat sealing the detonating tube The tail sealing device 5, the detonating tube feeding mechanism 1 is used to sequentially send the detonating tube 6 into the label feeding cutting device 2 and the tube winding turntable device 3, and the tube winding turntable device 3 is used for winding and detonating The detonating tube 6 sent by the tube feeding mechanism 1, the wire binding mechanism 4 is used to bundle the detonating tube 6 rewound to the set length by the tube rewinding turntable device 3, and the marking cutting device 2 includes a tube pressing mechanism 7 , the cutting mechanism 8 for cutting off the nonel tube 6 and the label feeding mechanism 9 for sending the label into the tube crimping mechanism 7, and the tu...

Embodiment 2

[0081] The difference between this embodiment and the first embodiment is that: the label feeding and cutting device, the tube winding and winding turntable device, the thread binding mechanism and the tail sealing device are all arranged symmetrically on the left and right, and there are also a feeding seat and a transposition push cylinder , the nonel feeding mechanism and the two tail sealing devices are arranged on the feeding seat and the nonel feeding mechanism is arranged between the two tail sealing devices, and the transposition push cylinder is connected with the feeding seat.

[0082] Work process and working principle of the present invention:

[0083] After the detonating tube is cut off by the marking cutting device, the transposition push cylinder pushes the detonating tube feeding mechanism to connect with another marking cutting device. While heat-sealing the cut-off detonator, feed the other marking cutting device. Similarly, when the detonator feeding mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com