Management device for automated guided vehicle (AGV) lead-acid storage battery

A lead-acid battery and management device technology, applied in battery/fuel cell control devices, secondary batteries, control devices, etc., can solve the problems of lead-acid battery service life impact, overcharging, lead-acid battery damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

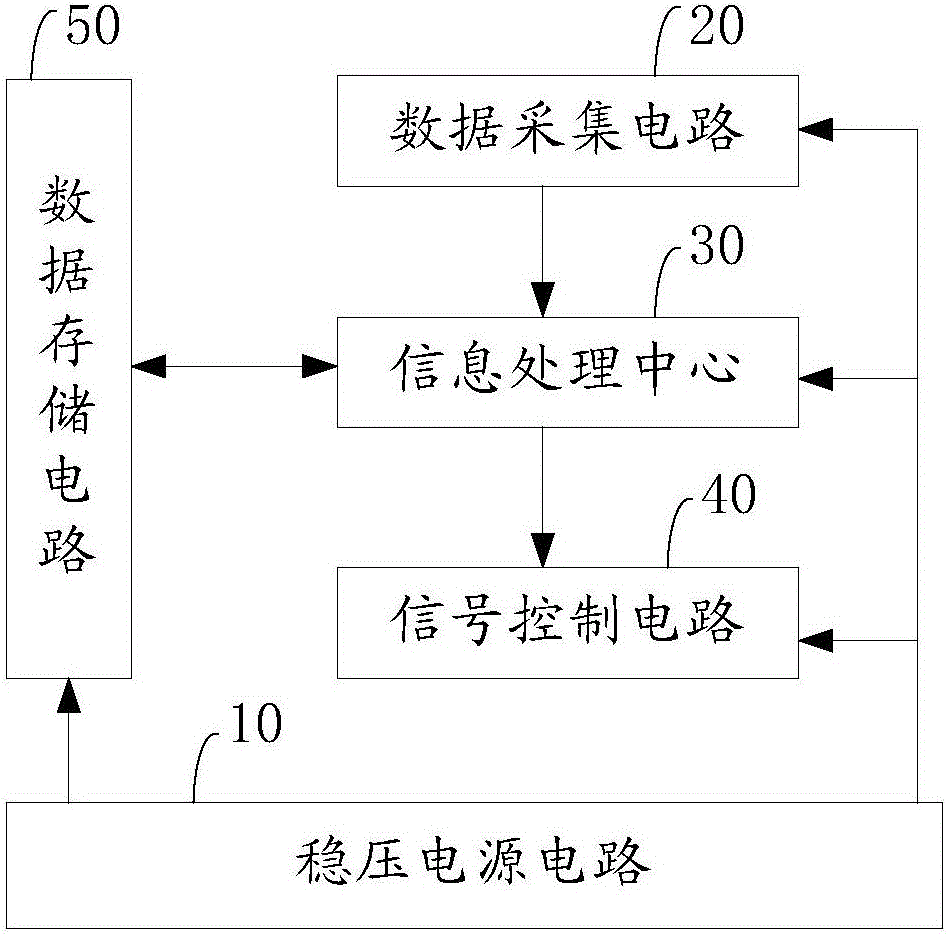

[0030] figure 1 The management device of the lead-acid storage battery for AGV vehicle according to the present invention is shown, including: a voltage stabilized power supply circuit 10, a data acquisition circuit 20, an information processing center 30, a data storage circuit 50 and a signal control circuit 40;

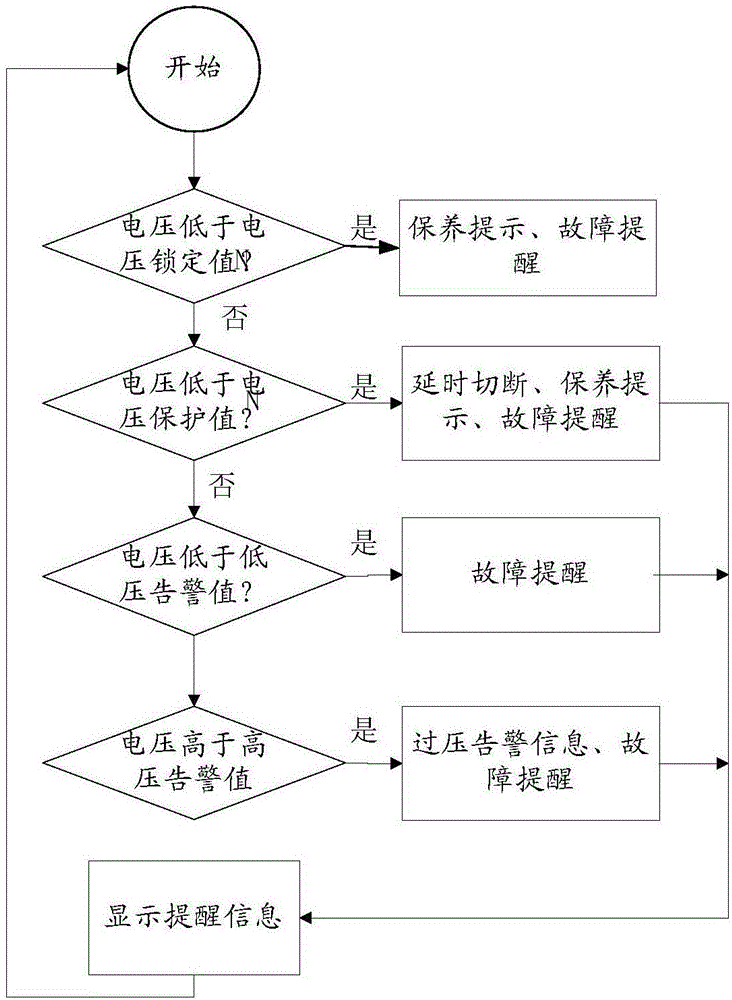

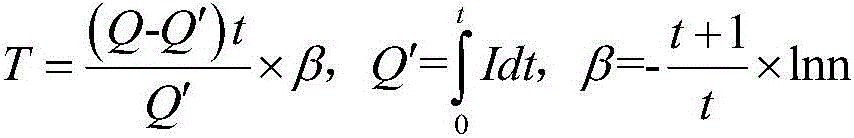

[0031] The stabilized power supply circuit 10 takes electricity from the storage battery, and supplies power for other circuits and the information processing center 30 of the management device of the present invention; the data acquisition circuit 20 collects the voltage value V of the storage battery in real time. i , and sent to the information processing center 30; the state para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com