Kitchen waste disposal machine and method

A kitchen waste and processor technology, applied in chemical instruments and methods, filtration treatment, heating water/sewage treatment, etc., can solve the problems of attracting mosquitoes, pungent odor, peculiar smell, etc., to solve the problems of accumulation and old miscellaneous, Improve the utilization rate and the effect of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described in detail below; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

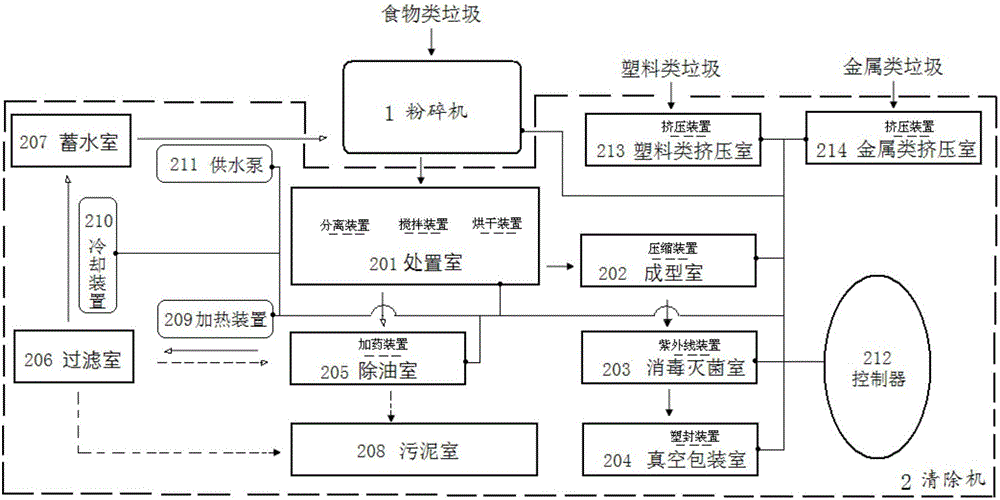

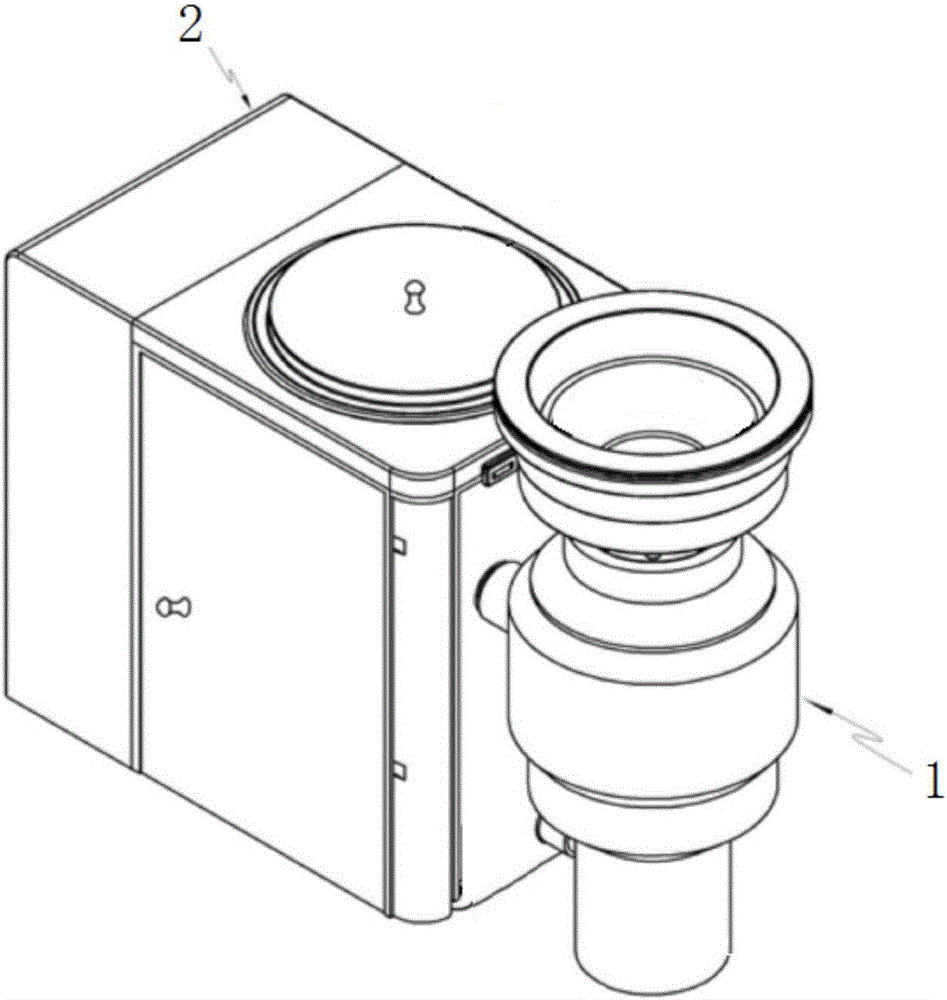

[0033] Such as Figure 1-2 Shown is the kitchen waste disposer in the preferred embodiment of the present invention, comprises pulverizer 1, and pulverizer 1 is provided with the inlet of putting in food waste and the discharge port of discharging the pulverized food waste, also includes connecting to all The cleaning machine 2 of the pulverizer 1 is mainly composed of a disposal chamber 201, a molding chamber 202, a disinfection and sterilization chamber 203, a vacuum packaging chamber 204, an oil removal chamber 205, a filter chamber 206, a water storage chamber 207, and a sludge chamber. 208. The plastic extrusion chamber 213 and the metal extrusion chamber 214 are composed, wherein, the disposal chamber 201 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com