A kind of modification method of molecular sieve

A molecular sieve and modification technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unfavorable heavy metals, unfavorable uniform dispersion, and poor structural stability of molecular sieves, etc., to increase the outer surface and degree of dispersion, avoiding uneven distribution, and effectively trapping heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

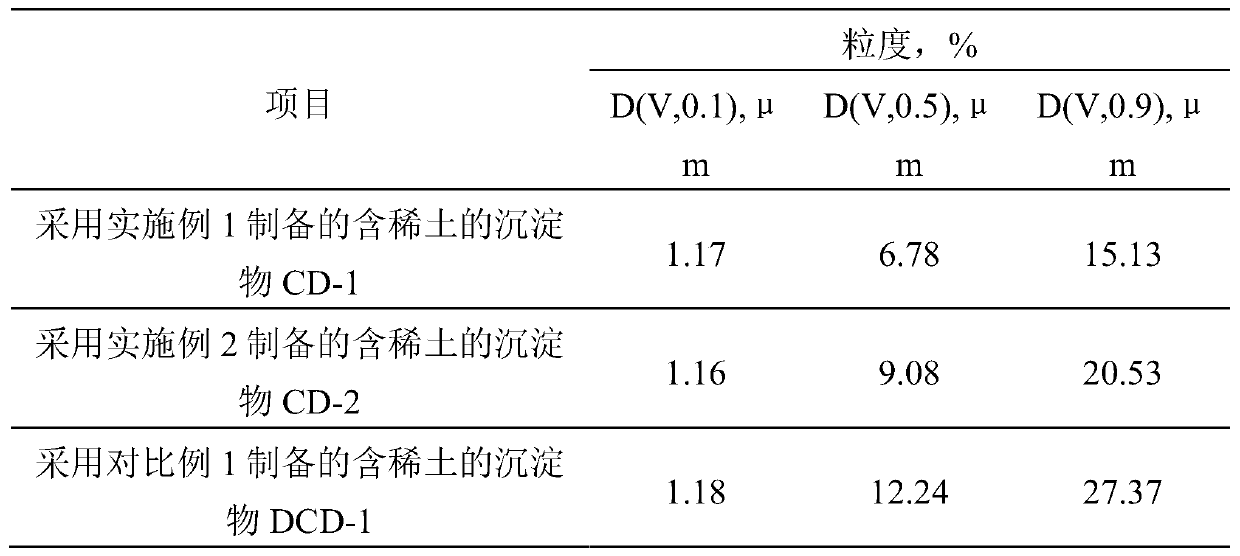

[0038] Mix 2g of citric acid, 2.48mL of rare earth nitrate and 75mL of deionized water to form a homogeneous solution, then add 2g of ammonium oxalate and stir for 15 minutes to form a rare earth-containing precipitate slurry CD-1.

Embodiment 2

[0040] Mix 2g of ethanol, 2.48mL of rare earth nitrate and 75mL of deionized water to form a uniform solution, then add 2g of ammonium oxalate and stir for 15 minutes to form a rare earth-containing precipitate slurry CD-2.

Embodiment 3

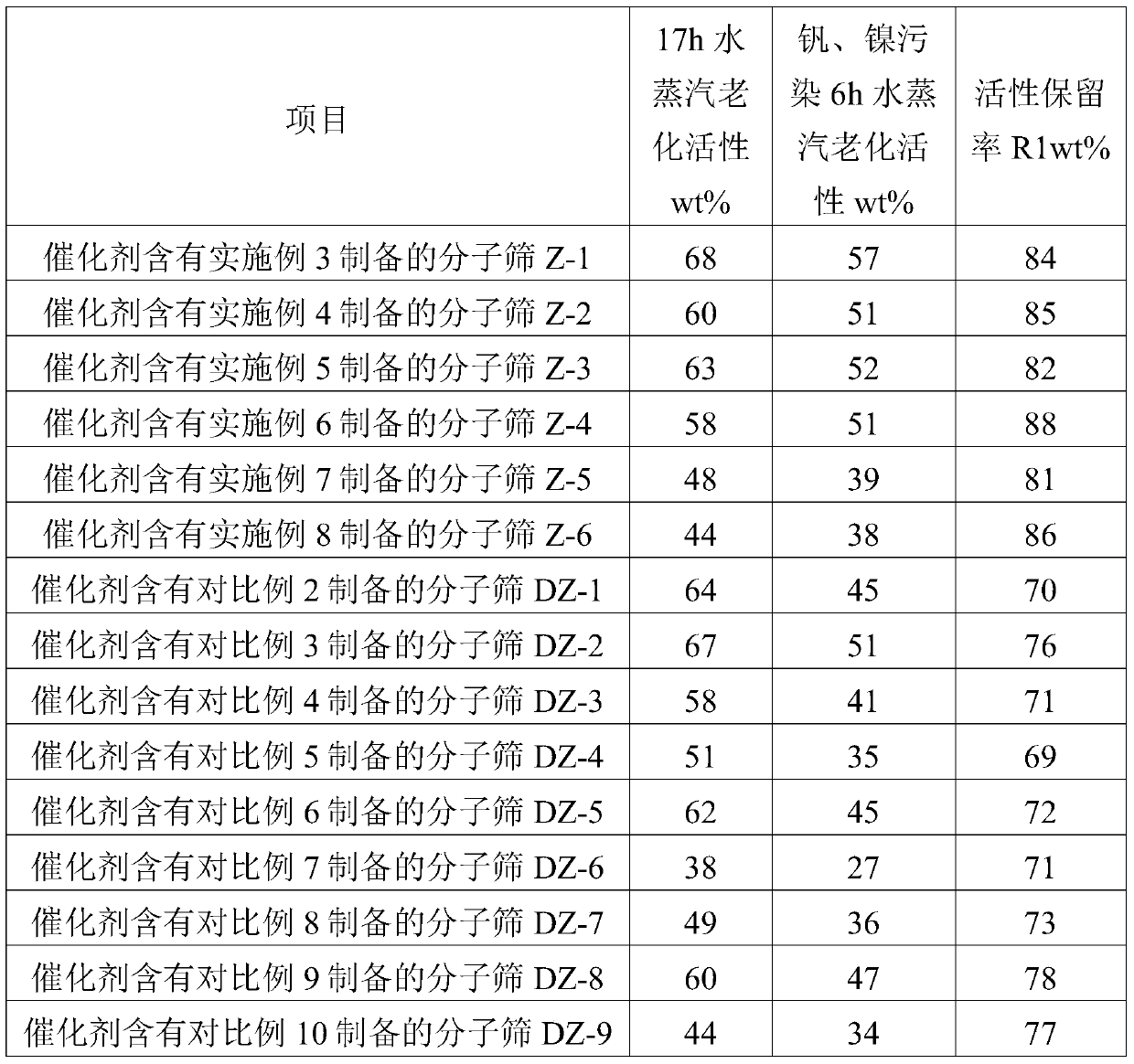

[0048] (1) Mix 16 g of citric acid, 4 g of ethylene glycol, 54 g of yttrium nitrate and 1 L of deionized water to form a uniform solution, then add 100 g of ammonium oxalate, and stir for 15 minutes to form a yttrium-containing precipitate slurry.

[0049] (2) Add the precipitate slurry formed in step (1) into the self-made yttrium-containing Y-type molecular sieve slurry Y-1, stir at a temperature of 55°C for 10 minutes, filter, wash with water, and filter the cake at 600°C and 100% steam Calcined under atmosphere for 2 hours. The modified molecular sieve Z-1 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com