Preparation method of supported palladium catalyst

A supported palladium and catalyst technology, applied in the field of catalysis, can solve problems such as complex process and difficult conditions, and achieve high activity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

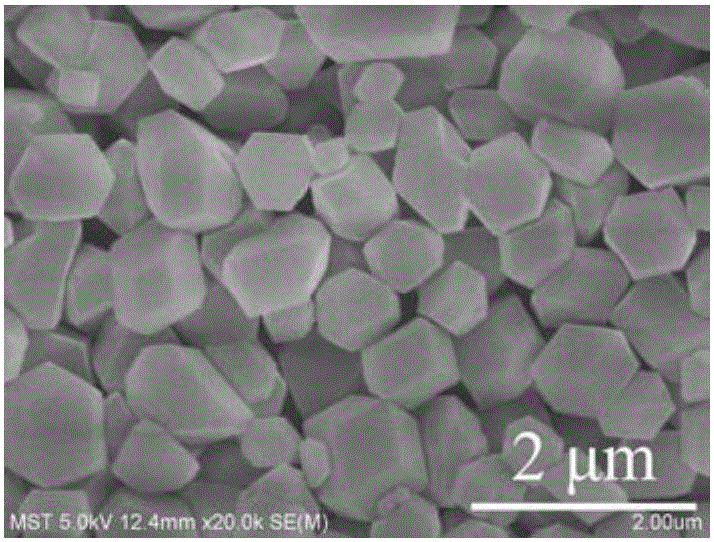

[0030] (1) Preparation of ZIF-67

[0031] First prepare 50 mL of 0.8 mol / L 2-methylimidazole methanol solution, 50 mL of cobalt nitrate hexahydrate, and 0.135 mol / L methanol mixed solution of polyvinylpyrrolidone concentrations respectively. First put the 2-methylimidazole solution in a 250mL Erlenmeyer flask, add the mixed solution of cobalt nitrate hexahydrate and polyvinylpyrrolidone under stirring, mix and stir for 5 minutes, and let stand for 24 hours. Centrifuge, wash twice with methanol, and finally place in an oven at 80°C for 6 hours.

[0032] (2) Preparation of CN carrier

[0033] 0.5g ZIF-67 was placed in a tube furnace and calcined at 600°C for 5h in an argon atmosphere. The temperature was raised from room temperature to the target temperature at a rate of 1°C / min. Calcined samples are denoted as Co / CN 600 . Prepared Co / CN 600 Pass through a 30% nitric acid solution, pickle at 60°C for 3 hours under continuous stirring, wash with deionized water 4 times, and...

Embodiment 2

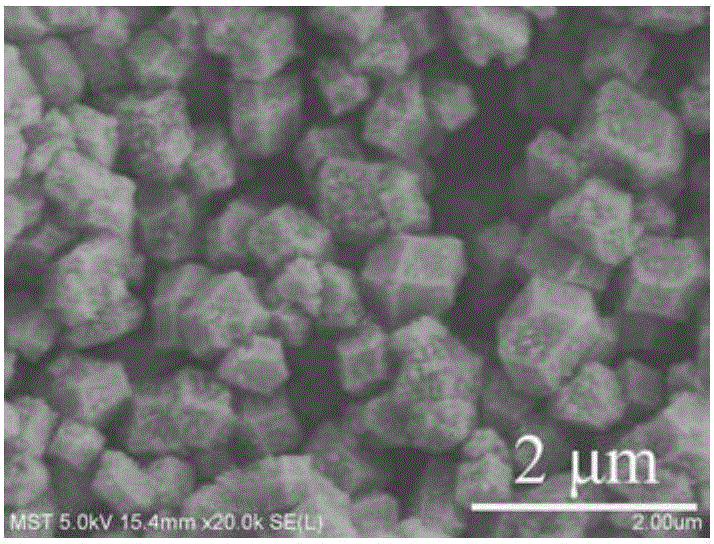

[0039] (1) Preparation of ZIF-67

[0040]First prepare 40 mL of 0.1 mol / L methanol solution of 2-methylimidazole, 60 mL of methanol mixed solution with concentrations of 0.013 mol / L and 0.017 mol / L of cobalt nitrate hexahydrate and polyvinylpyrrolidone respectively. First put the 2-methylimidazole solution in a 250mL Erlenmeyer flask, add the mixed solution of cobalt nitrate hexahydrate and polyvinylpyrrolidone under stirring, mix and stir for 10 minutes, and let stand for 12 hours. Centrifuge, wash with methanol three times, and finally place in an oven at 60°C for 10 hours.

[0041] (2) Preparation of CN carrier

[0042] 0.5g ZIF-67 was placed in a tube furnace and calcined at 600°C for 5h in an argon atmosphere. The temperature was raised from room temperature to the target temperature at a rate of 0.5°C / min. Calcined samples are denoted as Co / CN 600 . Prepared Co / CN 600 After passing through nitric acid solution with a mass concentration of 15%, pickling at 60°C for ...

Embodiment 3

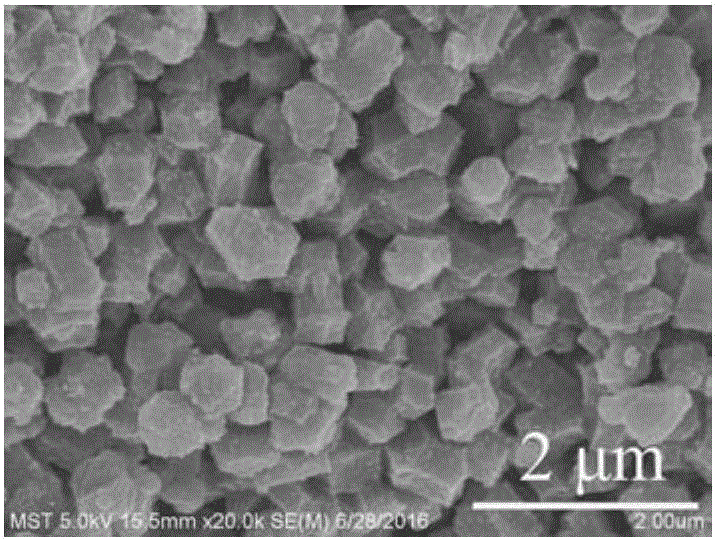

[0047] (1) Preparation of ZIF-67

[0048] First prepare 25 mL of 0.4 mol / L methanol solution of 2-methylimidazole, 75 mL of methanol mixed solution with concentrations of 0.05 mol / L and 0.068 mol / L of cobalt nitrate hexahydrate and polyvinylpyrrolidone respectively. First put the 2-methylimidazole solution in a 250mL Erlenmeyer flask, add the mixed solution of cobalt nitrate hexahydrate and polyvinylpyrrolidone under stirring, mix and stir for 8 minutes, and let stand for 18 hours. Centrifuge, wash with methanol three times, and finally place in an oven at 90°C for 7 hours.

[0049] (2) Preparation of CN carrier

[0050] 0.5g ZIF-67 was placed in a tube furnace and calcined at 700°C for 4.5h in an argon atmosphere. The temperature was raised from room temperature to the target temperature at a rate of 2°C / min. Calcined samples are denoted as Co / CN 700 . Prepared Co / CN 700 After passing through a nitric acid solution with a mass concentration of 20%, pickling at 60°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com