High-Q value phononic crystal resonator-type acoustic energy harvester

A phononic crystal and resonant cavity technology, which is applied in the field of high-Q phononic crystal resonant cavity type acoustic energy collectors, achieves high-efficiency acoustic energy collection efficiency, less use of structural materials, and enhanced acoustic wave amplification and acoustic energy convergence capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

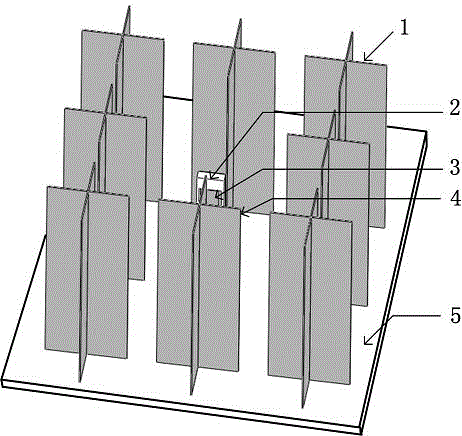

[0023] The specific embodiment of the present invention is as figure 1 shown.

[0024] In this embodiment, a high-Q phononic crystal resonator-type acoustic energy harvester includes a high-Q phononic crystal resonator 1 , an electromechanical Helmholtz resonator, a support column 4 and a base 5 .

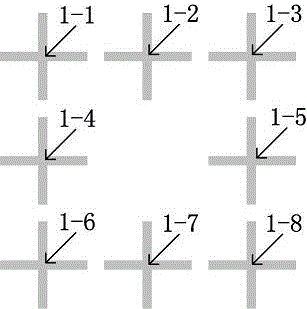

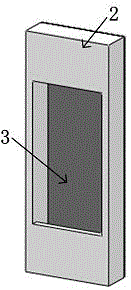

[0025] The high-Q phononic crystal resonator 1 is formed by arraying 8 sets of cross vertical plates (1-1, 1-2, ..., 1-8) at equal intervals along two directions perpendicular to each other in the same plane, and the Its bottom is glued on the base 5, and a cavity is left in the center of the cross riser array to form a resonant cavity. The electromechanical Helmholtz resonator is composed of a Helmholtz resonator 2 and a composite piezoelectric transducer 3, and the composite piezoelectric transducer 3 is bonded to the back of the Helmholtz resonator 2 in a fixed manner at the peripheral end. cavity position; wherein the composite piezoelectric transducer 3 is formed by bonding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com