Motor rotor and motor having motor rotor and compressor

A motor rotor and rotor technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of large angle range of cutting angle, unlimited size of cutting angle, and limited effect, so as to weaken the motor cogging torque and rotation speed. The effects of torque ripple, improved stability and reliability, and no reduction in motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described below based on examples, but the present invention is not limited to these examples.

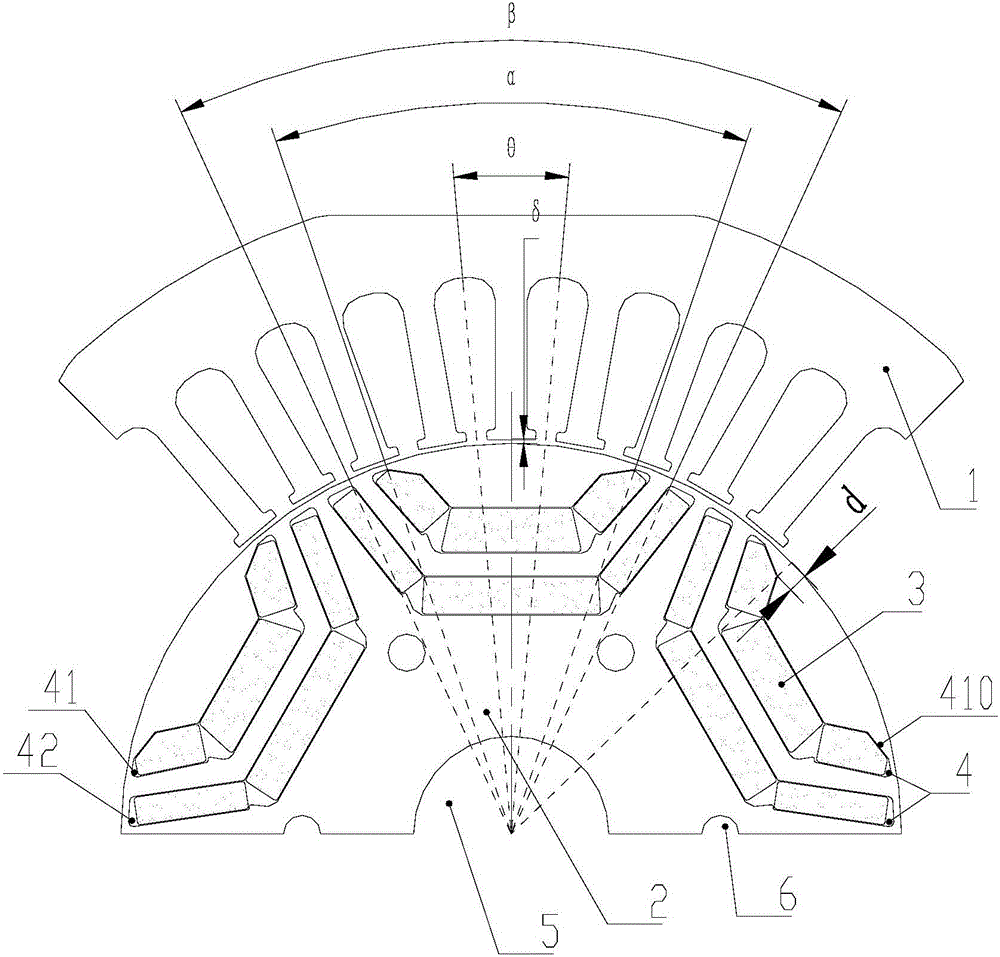

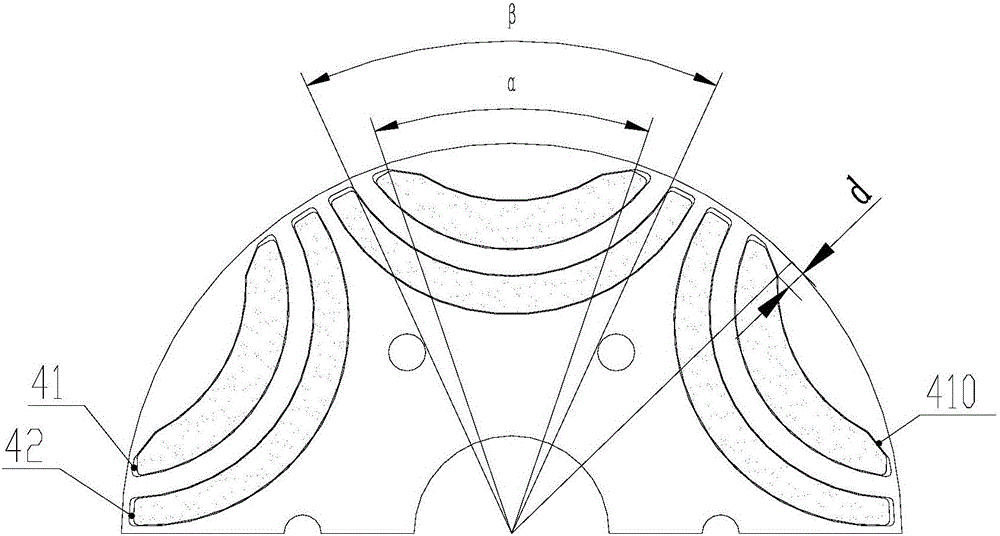

[0030] Such as Figure 1-3 As shown, the first aspect of the present invention provides a motor rotor, preferably a permanent magnet synchronous reluctance motor rotor, which includes a rotor core 2 and a rotating shaft (not shown), etc., the rotor core 2 is provided with a magnet 3 (preferably permanent magnet, such as the magnet groove 4 of magnetic steel). In the preferred embodiment shown in the figure, the rotor core 2 is further provided with a connecting hole 6 and a shaft hole 5 for matching with a rotating shaft.

[0031] figure 1 Also shows a part of the iron core 1 of the stator matched with the motor rotor, wherein an air gap is formed between the stator and the rotor, and the width of the air gap is denoted as δ; at the same time, the stator includes teeth uniformly arranged along the circumferential direction Slots (that is, winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com