Leakage test clamp for exhausting manifold

An exhaust manifold and leak test technology, which is applied in fluid tightness testing, machine/structural component testing, and by measuring fluid growth and deceleration rates, can solve problems such as the complex shape of exhaust manifolds, and achieve the goal of using Easy to adjust, good detection effect, convenient ventilation side leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

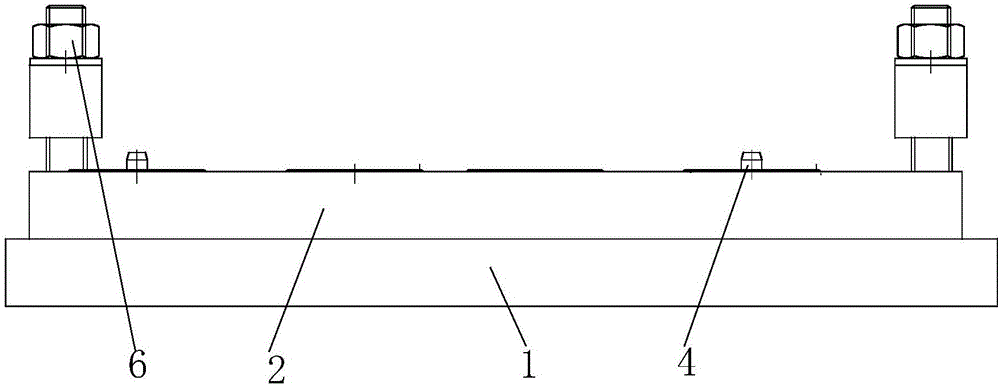

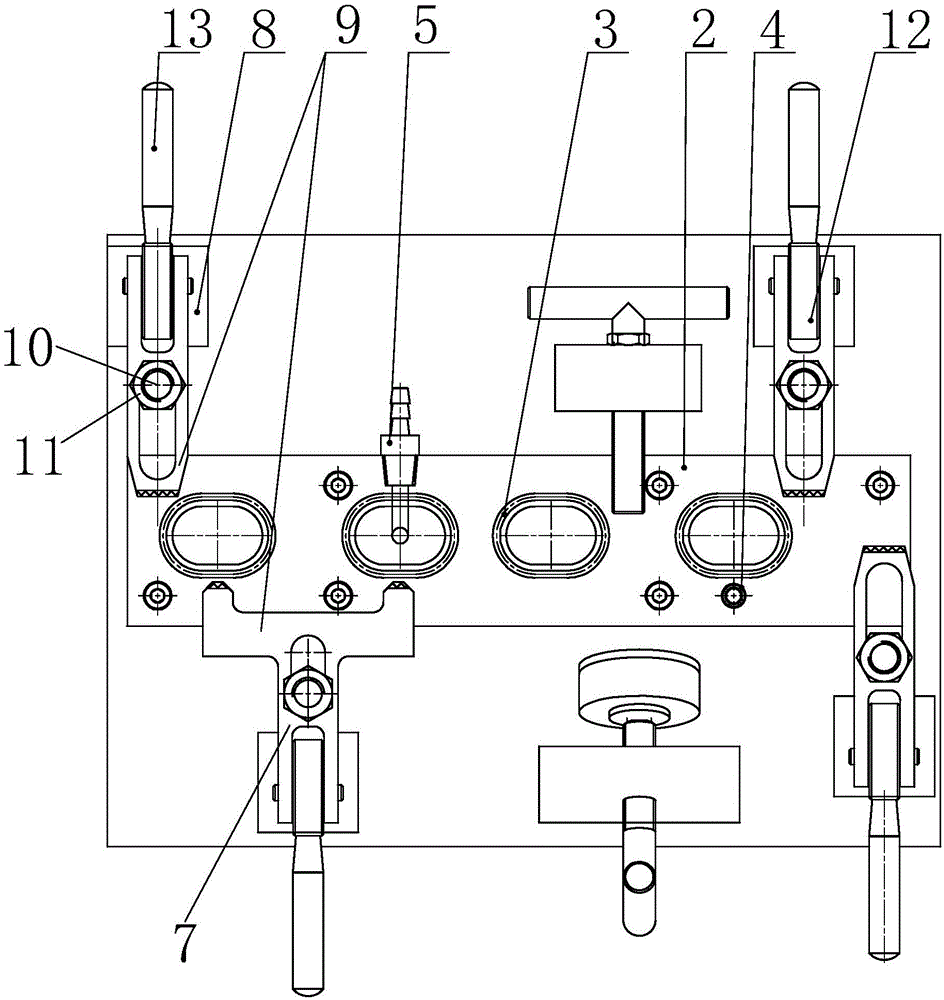

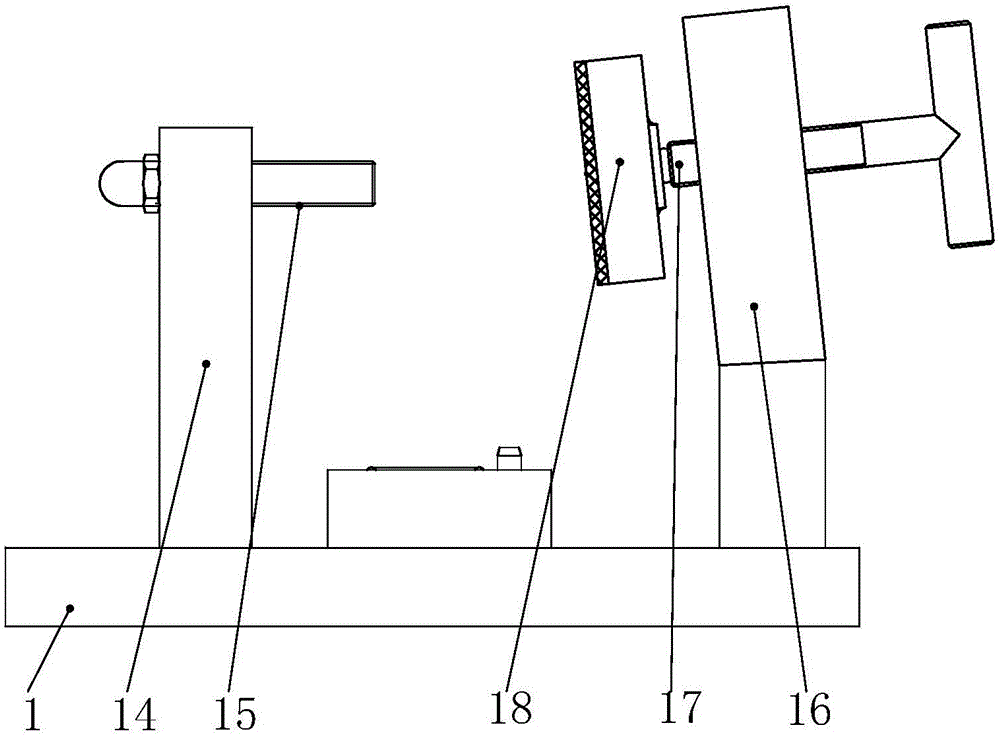

[0025] Such as Figure 1 to Figure 7 As shown, a leak test fixture for an exhaust manifold includes a clamp body 1, a pad 2 is installed in the upper middle of the clamp body 1, and four seals are installed on the pad 2 along the horizontal direction. Ring 3, cylindrical pins 4 are installed on the upper left end and right end of the pad 2, and a pipe joint 5 connected to the surface of the clamp body 1 is installed on the rear end of the pad 2.

[0026] Two No. 1 clamping and fixing devices 6 are installed on the upper rear of the clamp body 1, and a No. 1 clamping and fixing device 6 and a No. 2 clamping and fixing device 7 are installed on the upper front of the clamp body 1. The No. 1 clamping and fixing device 6 and the No. 2 clamping and fixing device 7 all include a pad 8 fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com