Energy-saving refrigerating device

A refrigeration device and controller technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reduced vacuum pump delivery efficiency, unsatisfactory cooling effect, and reduced refrigeration effect, so as to improve energy saving effect and provide condensation effect , The effect of reducing the working time of electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

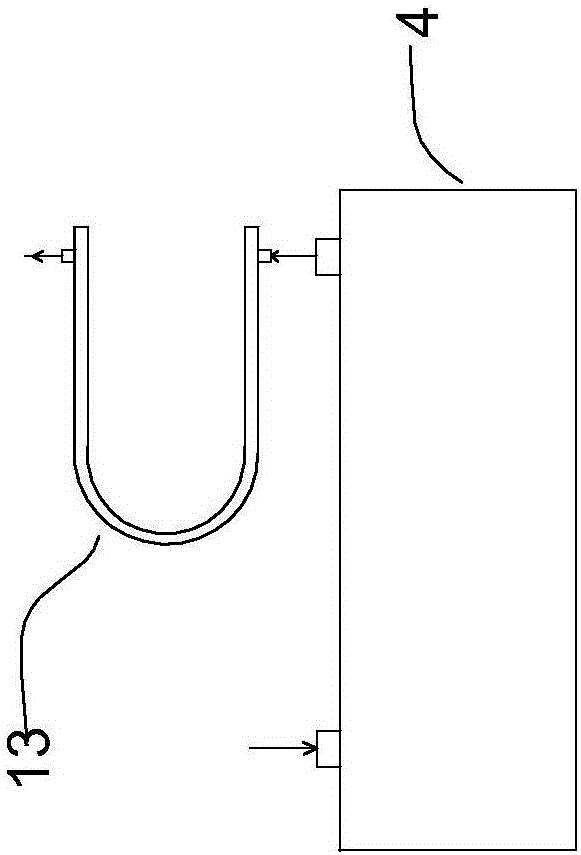

[0024] Such as Figure 1~5As shown, an energy-saving refrigeration device includes a device casing, an evaporator 1, a first cooling reducer 2, a second cooling reducer 3, a vacuum pump 4, a spray nozzle 5, a first one-way valve 6, a second Main components such as check valve 7, dryer 8 and connecting pipelines, among which the evaporator 1 is formed by connecting the vertical metal tube 1.1 and the horizontal metal tube 1.2. Usually, the vertical metal tube 1.1 is 3 arranged in parallel, and the horizontal metal tube 1.2 There are 15 pieces arranged side by side. The diameter of the vertical metal pipe 1.1 is thicker than that of the horizontal metal pipe 1.2. They can be made of stainless steel pipes or copper pipes. When connected, they are connected to form a metal disk. Metal fins are distributed on the vertical metal tube 1.1 and the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com