Coalbed methane mining method with regulation and control of desorption and diffusion

A diffusion method, a technology for the development of coalbed methane, applied in the field of underground energy mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

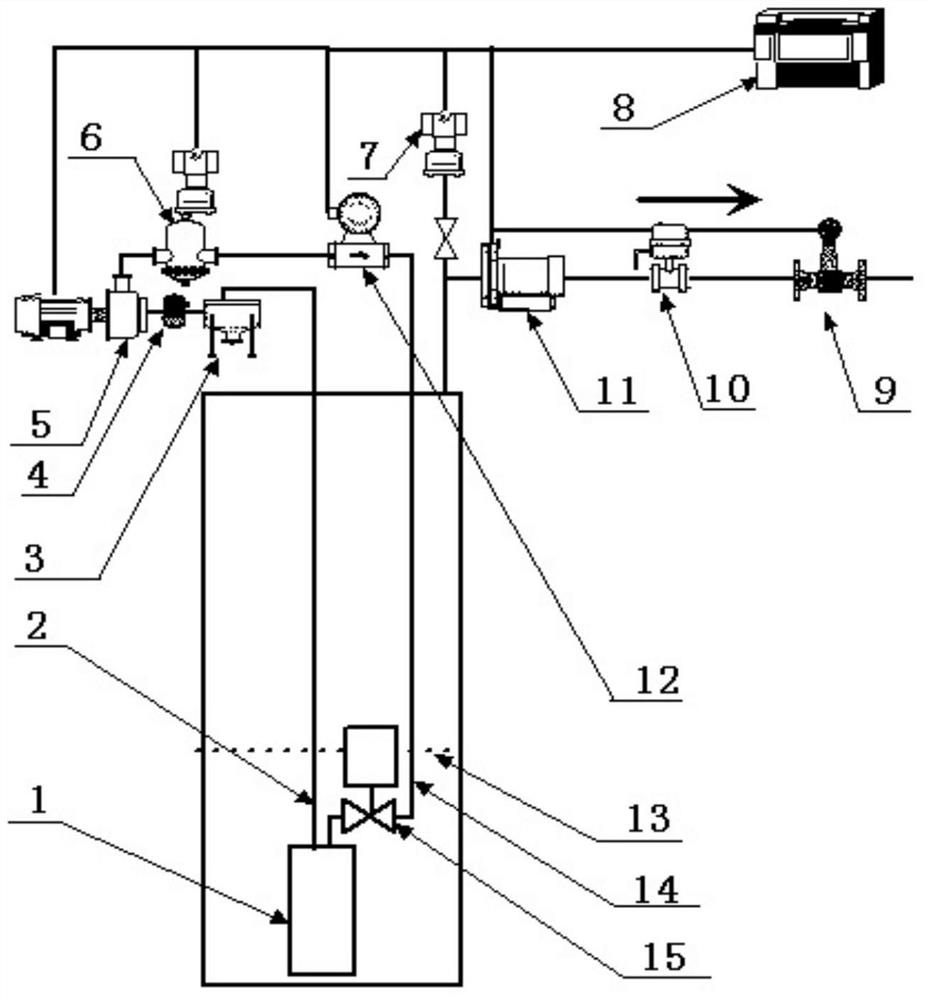

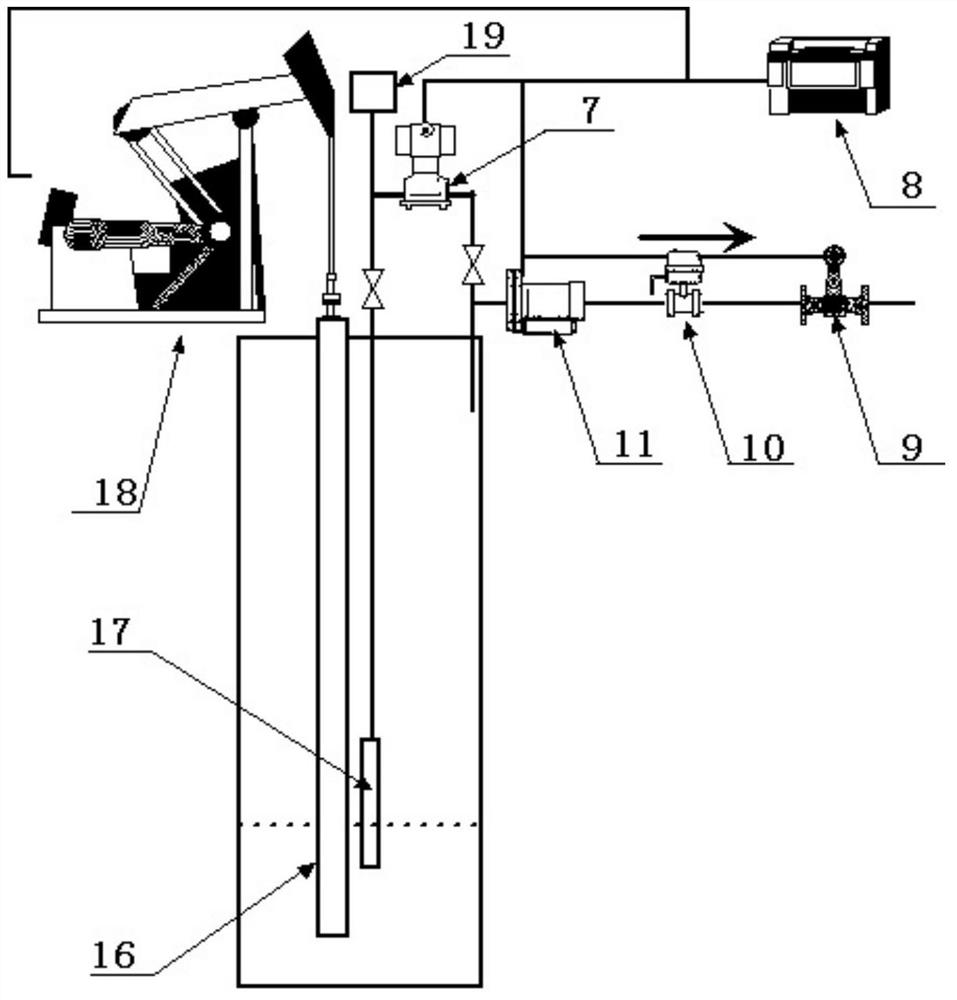

Image

Examples

Embodiment Construction

[0041] To implement the coalbed methane mining method for controlling desorption and diffusion of the present invention, relevant implementation plans should be formulated according to the geological conditions of the coalbed on site. First, a small number of experimental wells should be selected for preliminary test evaluation, and then gradually expanded.

[0042] Before test, should fully consider following characteristics of the present invention:

[0043] 1. Since the frequency of the pressure wave is very low, it will travel far in the coal seam. During the process of absorbing the pressure wave by the coal seam microstructure, there will be opportunities for wave trough superposition. This wave trough superposition will promote the desorption and cutting of coalbed methane. Expansion and connection of rifts and fissures;

[0044] 2. Since the fluctuating pressure is relatively small compared with conventional operations, it can only form elastic changes in the microstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com