Technology combining horizontal drilling and profile control blocking

A combined process and horizontal technology, applied in sealing/isolation, drilling equipment and methods, drilling equipment, etc., can solve problems such as the inability to guarantee the oil increase effect, the inability to control high-permeability strips, and the inability to fully activate low-permeability layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

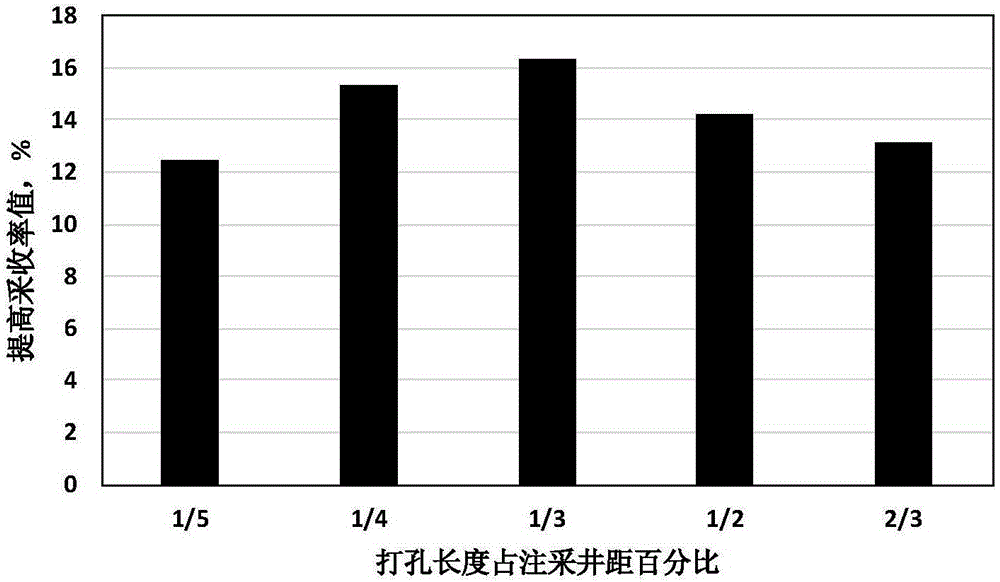

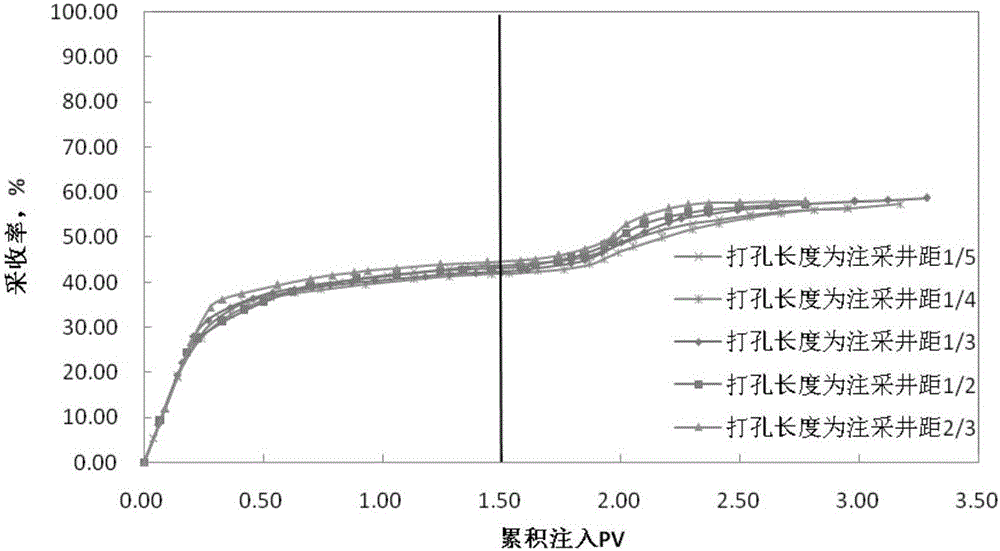

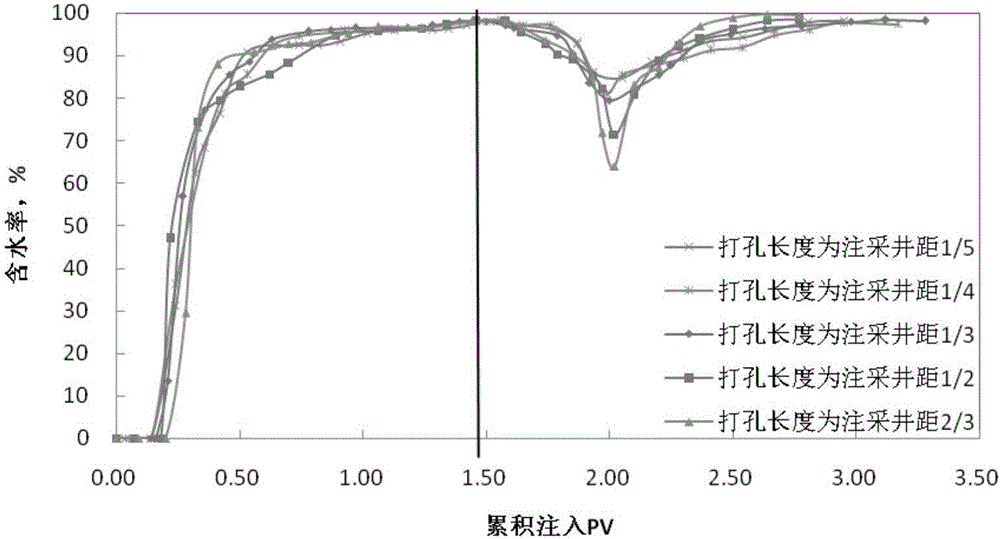

[0029] Through the description of the process of determining the drilling length, drilling direction and drilling timing, it is shown that the combined process of asphalt profile control and horizontal drilling has obvious effects of increasing oil and reducing water:

[0030] 1. Determination of the punching length

[0031] Five three-layer heterogeneous cores were taken, and the effective permeability in the vertical direction was 500mD, 1000mD, and 3000mD respectively. Well layout is carried out according to the five-point method. After saturated with oil, water is flooded to 98% of the water content, and asphalt particle profile control fluid is injected, and then 1 / 5, 1 / 4, 1 / 3, and 1 / 2 of the injection-production well spacing are used in the uppermost layer. , 2 / 3 respectively for punching. The input-output ratio was calculated according to the increase of recovery rate and the change value of water cut, and the optimal drilling length was optimized. The experimental res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com