High water cut later oil reservoir flow field grading evaluation method

An evaluation method and flow field technology, applied in earthwork drilling, data processing application, measurement, etc., can solve the problems of result uncertainty, error, large range of human factors in grading levels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] A method for grading and evaluating the flow field of a high water-cut reservoir in the late stage, comprising the following steps:

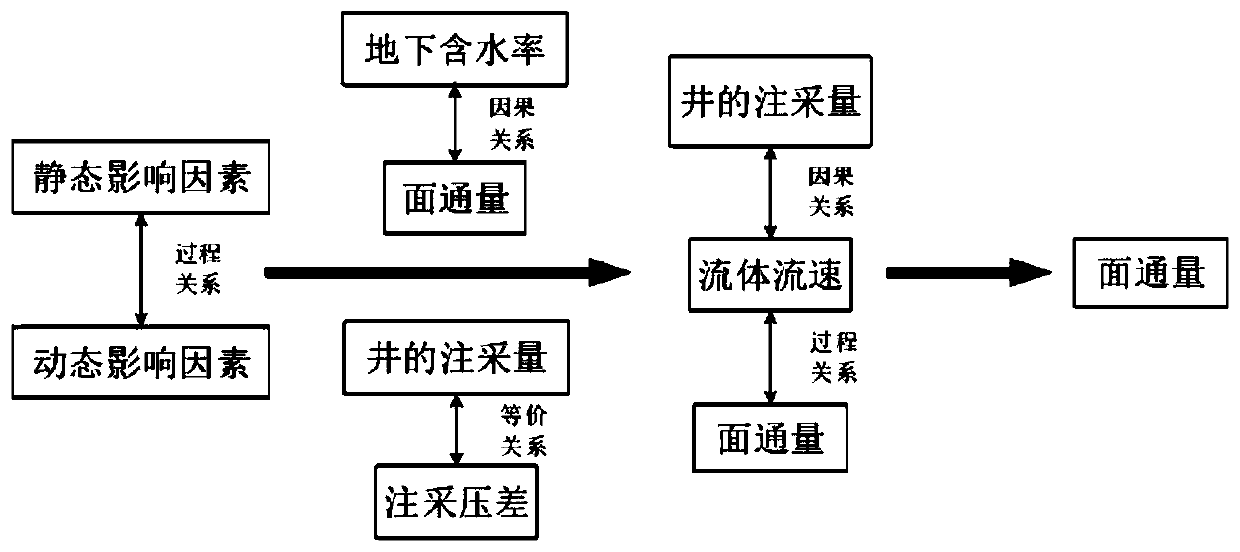

[0044] S1. Comprehensively analyze the static and dynamic factors affecting the reservoir flow field, use the logic analysis method to screen out the appropriate flow field evaluation index, and finally determine the surface flux as the only index for reservoir flow field evaluation, such as figure 1 ;

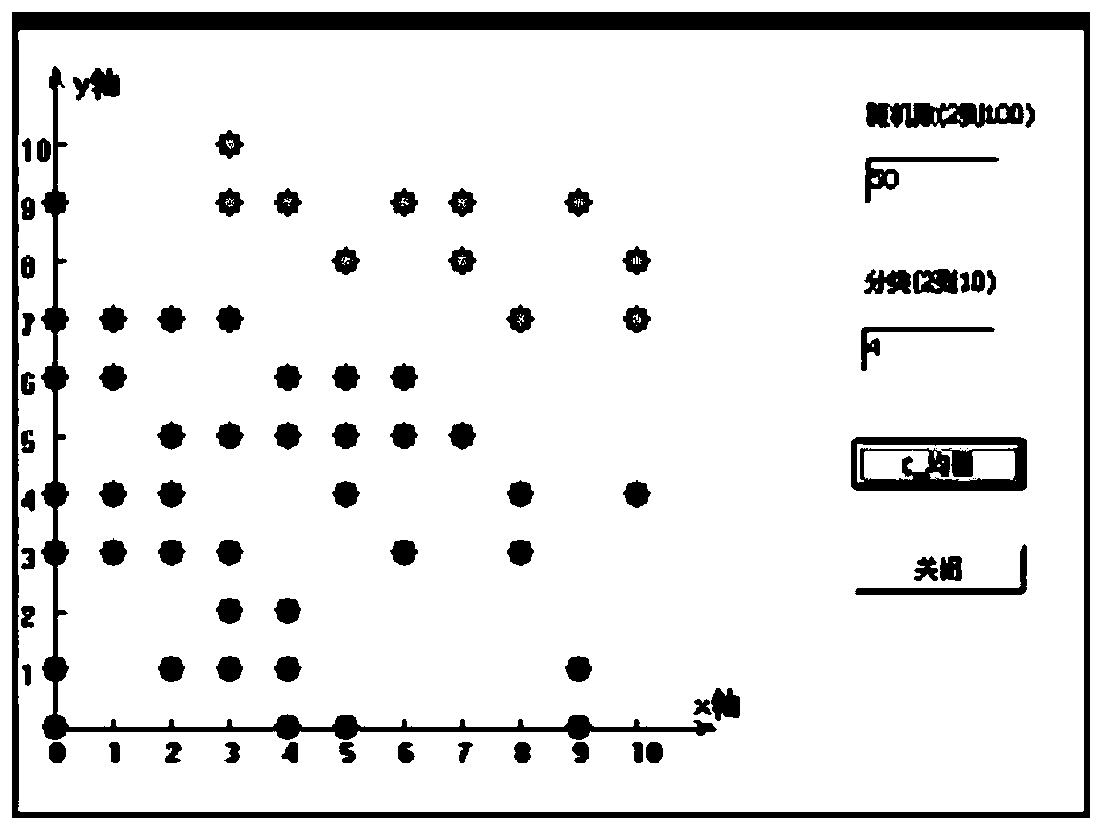

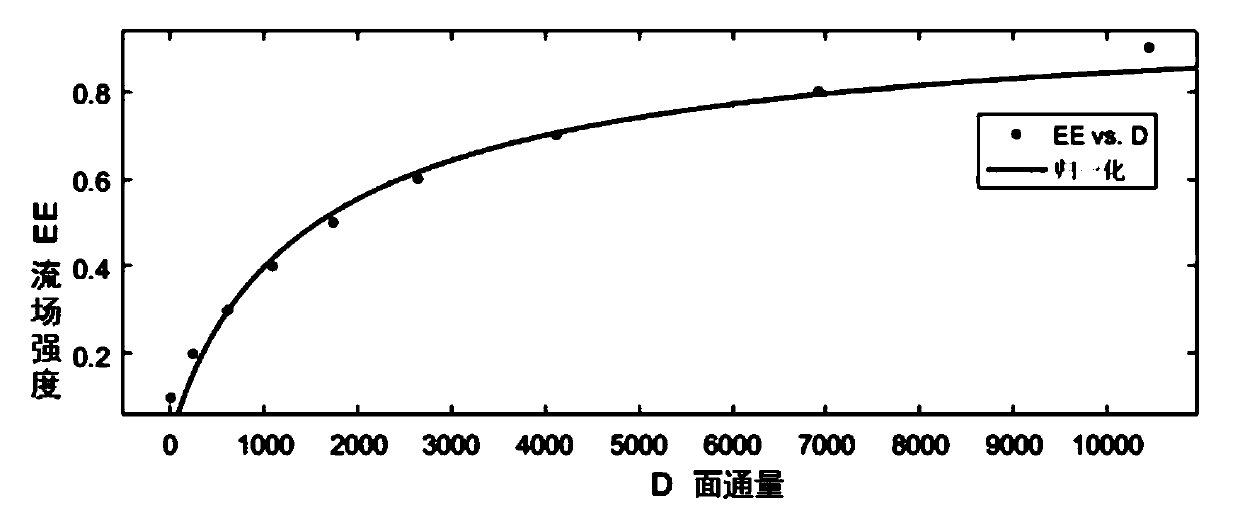

[0045] S2. Carry out preliminary cluster analysis on the surface flux field data exported by ECLIPSE. The original surface flux field data are as follows: Figure 5 As shown in , the surface fluxes are clustered using fuzzy C-means clustering analysis to obtain the cluster center an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com