A quick detachable suspension shuttle type reversible feeding line

A material supply line and fast technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of low construction efficiency, large construction interference, and difficult installation, so as to improve construction efficiency, make safety simple, and install convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

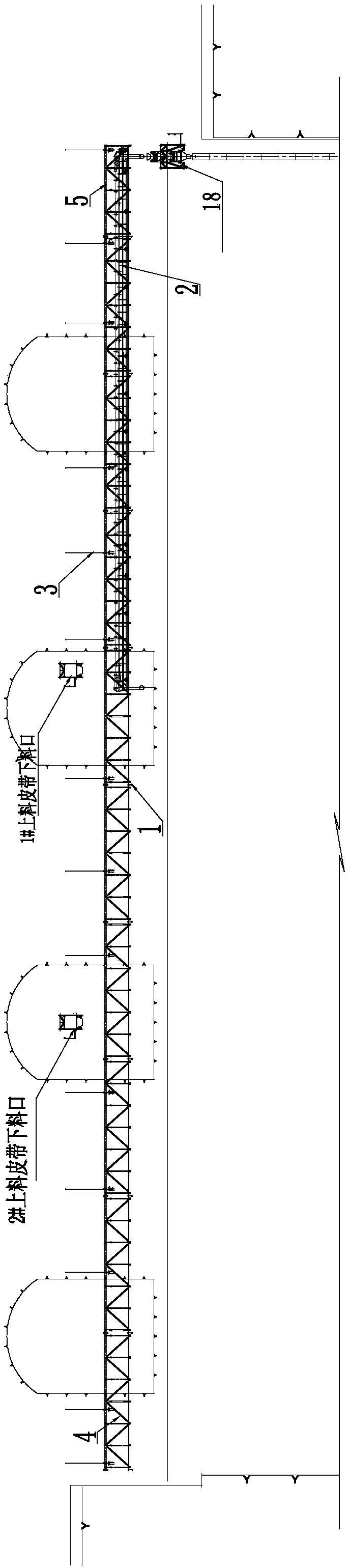

[0024] Such as Figure 1~Figure 6 As shown, a quick-detachable suspension shuttle-type reversible feeding line includes a truss 1 , a shuttle-type reversible belt conveyor 2 , and a suspension system 3 .

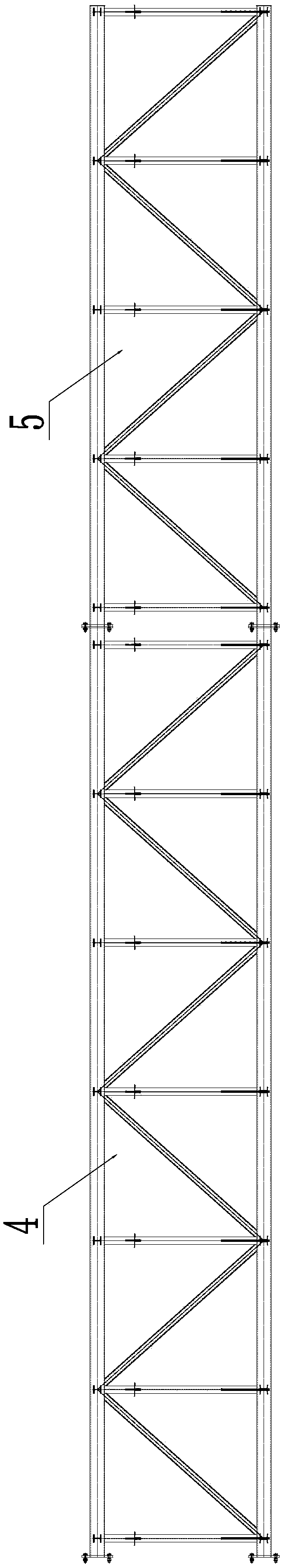

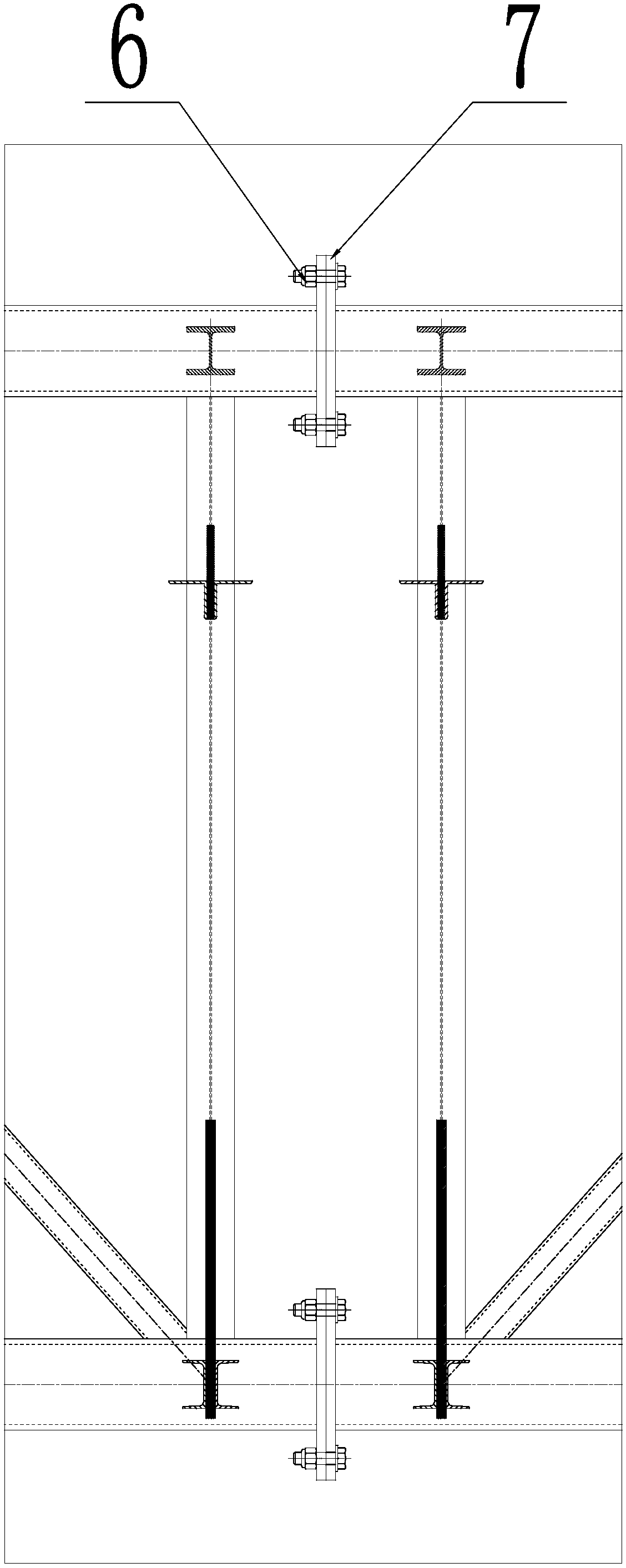

[0025] The truss 1 is composed of a plurality of standard sections 4 and a makeshift section 5, and two adjacent standard sections 4, and between the standard section 4 and the makeshift section 5 are connected by means of bolts 6 riveting connecting plates 7.

[0026] The shuttle-type reversible belt conveyor 2 is arranged on the track 8 inside the truss 1, the shuttle-type reversible belt conveyor 2 has its own walking function, the shuttle-type reversible belt conveyor 2 can translate in the truss 1, and the belt steering is reversible.

[0027] The suspension system 3 is mainly composed of a cantilever beam 9, a diagonal stay 12 and a steel corbel. The cantilever beam 9 is welded to the steel corbel 10 at the bottom, and the basket bolt 13 is arranged in the middle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com