Waterproof coiled material hot melting edge sealing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

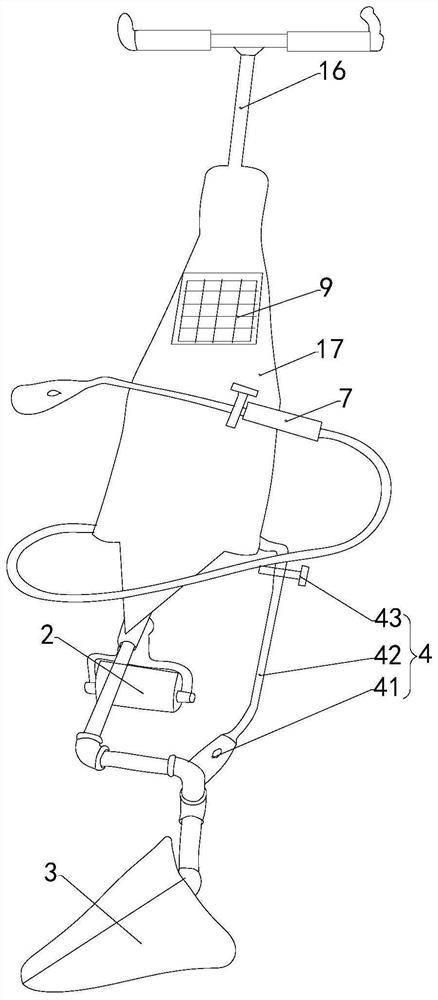

[0040] Such as Figure 1 to Figure 6 As shown, a waterproof coiled material hot-melt edge banding machine of the present embodiment includes a frame body 1, a pressure roller 2, a fire head 3 and a spray gun 4, the frame body 1 is provided with the pressure roller 2, the The pressure roller 2 is rollingly connected to the lower part of the frame body 1; the frame body 1 is provided with a fire head 3 and a spray gun 4, and the spray gun 4 includes a first connecting pipe 42 and a pipe mounted on one end of the first connecting pipe 42 Nozzle 41, the first connecting pipe 42 is provided with a control switch 43, the first connecting pipe 42 is installed on the frame body 1, the nozzle 41 and the fire starter 3 are respectively located on the frame body 1 On the same side as above, the spray head 41 and the ignition head 3 are arranged obliquely towards the bottom of the frame body 1 .

[0041] The first connecting pipe 42 of this embodiment can also be connected with a trimmin...

Embodiment 2

[0047] Such as figure 1 As shown, a waterproof coiled material hot-melt edge banding machine of the present embodiment includes a frame body 1, a pressure roller 2, a fire head 3 and a spray gun 4, the frame body 1 is provided with the pressure roller 2, the The pressure roller 2 is rollingly connected to the lower part of the frame body 1; the frame body 1 is provided with a fire head 3 and a spray gun 4, and the spray gun 4 includes a first connecting pipe 42 and a pipe mounted on one end of the first connecting pipe 42 Nozzle 41, the first connecting pipe 42 is provided with a control switch 43, the first connecting pipe 42 is installed on the frame body 1, the nozzle 41 and the fire starter 3 are respectively located on the frame body 1 On the same side as above, the spray head 41 and the ignition head 3 are arranged obliquely towards the bottom of the frame body 1 .

[0048] Such as figure 1 As shown, one end of the frame body 1 of the present embodiment is provided wit...

Embodiment 3

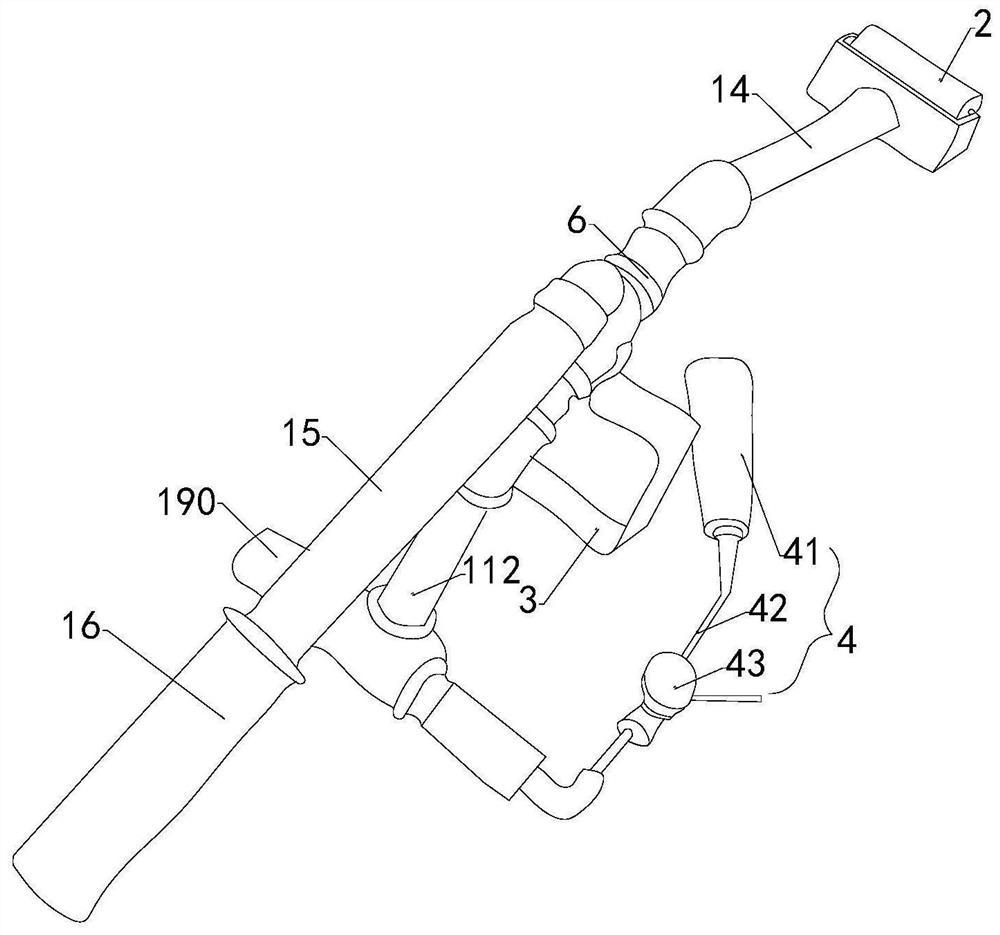

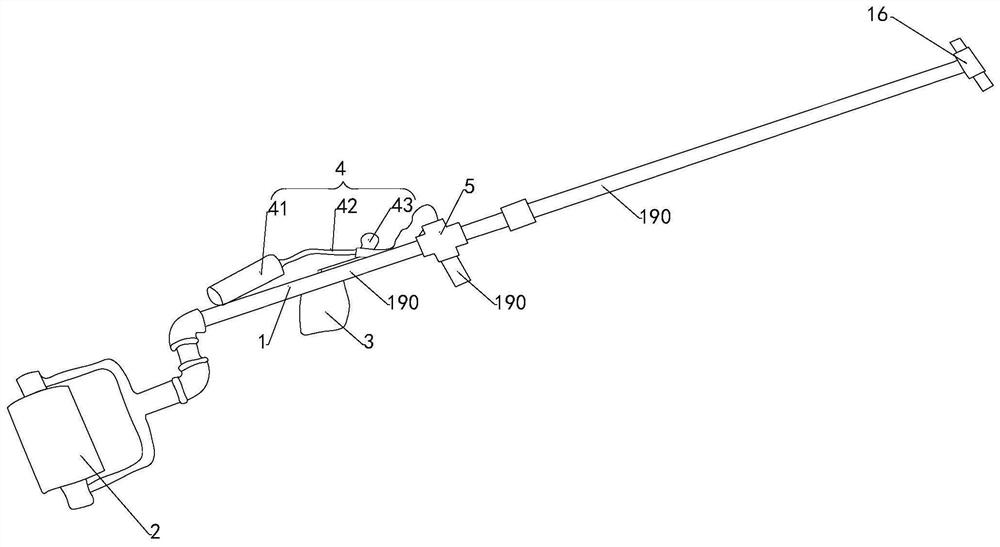

[0054] Such as figure 2 As shown, a waterproof coiled material hot-melt edge banding machine of the present embodiment includes a frame body 1, a pressure roller 2, a fire head 3 and a spray gun 4, the frame body 1 is provided with the pressure roller 2, the The pressure roller 2 is rollingly connected to the lower part of the frame body 1; the frame body 1 is provided with a fire head 3 and a spray gun 4, and the spray gun 4 includes a first connecting pipe 42 and a pipe mounted on one end of the first connecting pipe 42 Nozzle 41, the first connecting pipe 42 is provided with a control switch 43, the first connecting pipe 42 is installed on the frame body 1, the nozzle 41 and the fire starter 3 are respectively located on the frame body 1 On the same side as above, the spray head 41 and the ignition head 3 are arranged obliquely towards the bottom of the frame body 1 .

[0055] Such as figure 2 As shown, the frame body 1 includes a first section 14, a second section 15 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com