Method for constructing pressure pipeline and dam heavy curtain of head underground powerhouse

A technology for pressure pipelines and underground workshops, which is applied in the field of first-type underground workshop pressure pipelines and dam curtain grouting construction, can solve the problems of pressure pipeline anti-seepage "blind areas, adverse effects, restricting the construction progress of underground workshops, etc., to ensure anti-seepage." quality, solving construction disturbances, and ensuring the effect of dam anti-seepage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

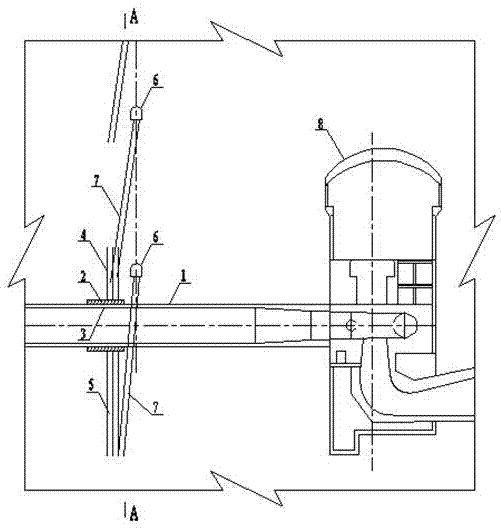

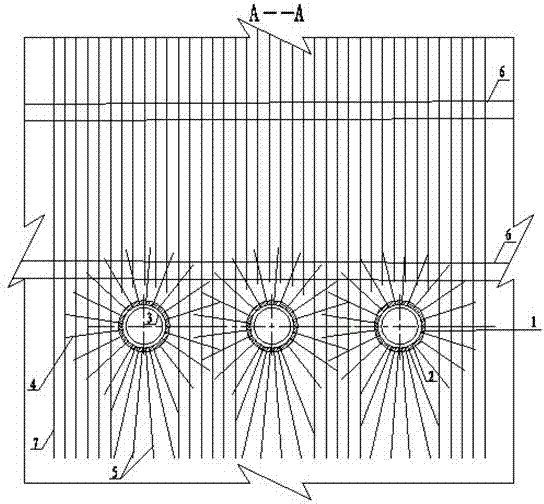

[0013] Such as figure 1 , figure 2 As shown, the pressure pipe and dam curtain construction method of the present invention is to expand and excavate the pressure pipe hole near the anti-seepage line of the dam curtain, and use the space of the expanded excavation to pour the first-stage concrete. After the first-stage concrete pouring is completed, Set several rows of pressure pipe circumferential radiation curtain grouting holes 4 along the first-stage concrete hole for curtain grouting. After the circumferential radiation curtain grouting construction is completed, conventional follow-up work for pressure pipes can be carried out, parallel to the dam curtain grouting During operation, the anti-seepage curtain of the dam and the circumferential radiation curtain grouting of the pressure pipeline are reasonably overlapped to form the anti-seepage curtain of the dam, which effectively solves the dilemma of mutual restriction between the curtain grouting of the dam and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com