Anti-seepage treatment structure and anti-seepage treatment method for intersected part of grouting curtain and water diversion pipeline

A treatment method and technology for grouting corridors, which are applied in infrastructure engineering, water conservancy engineering, hydropower generation, etc., can solve the problems of long construction period, complicated construction process of penstock and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

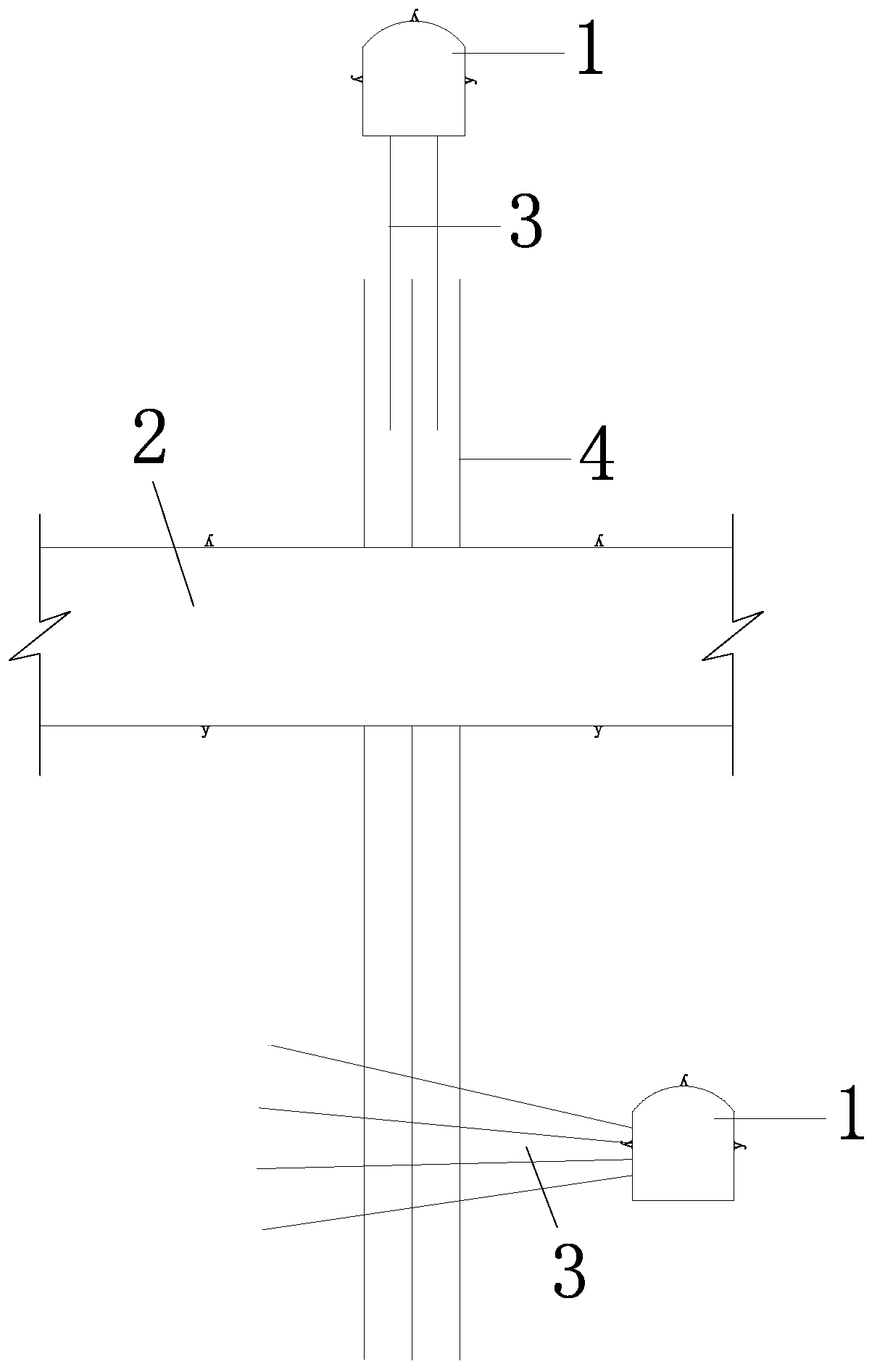

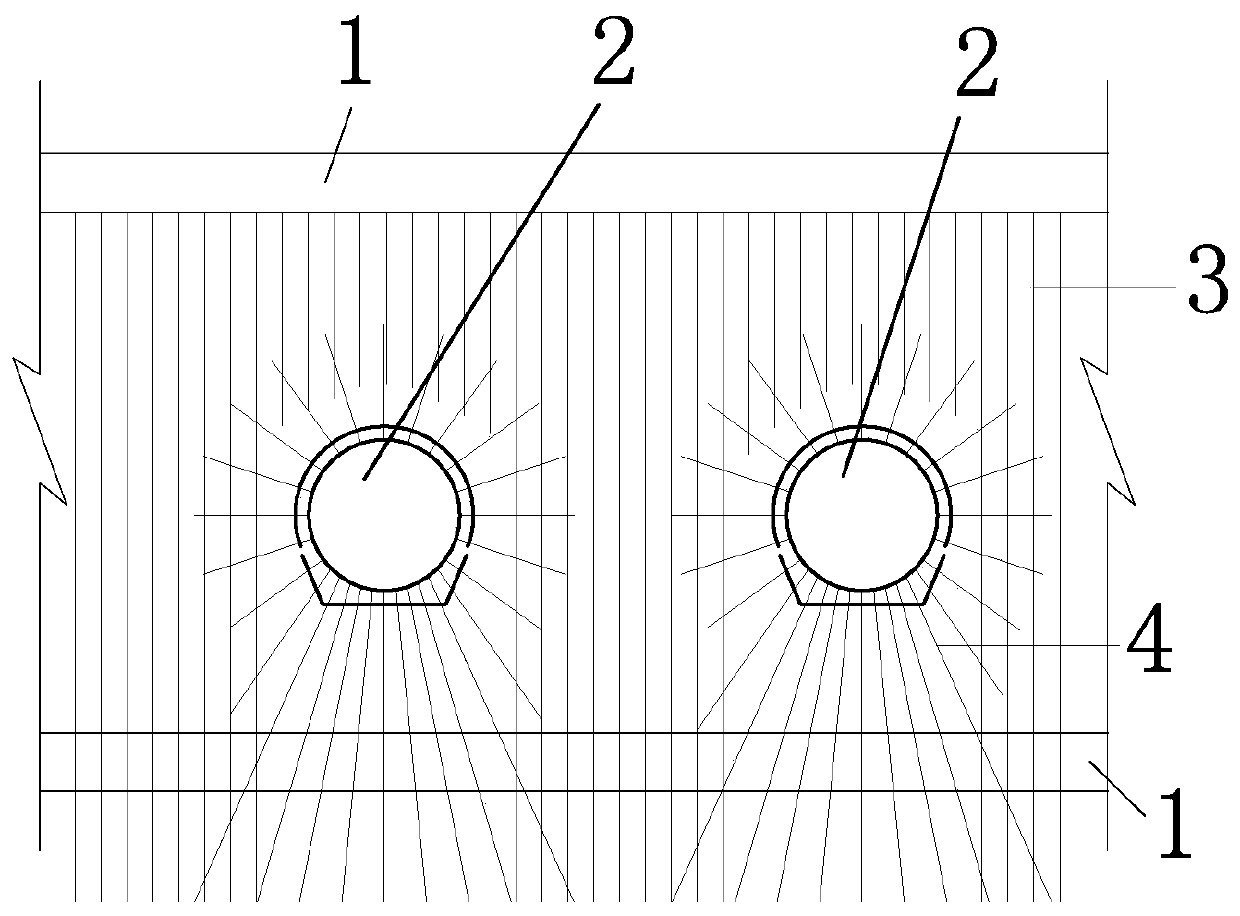

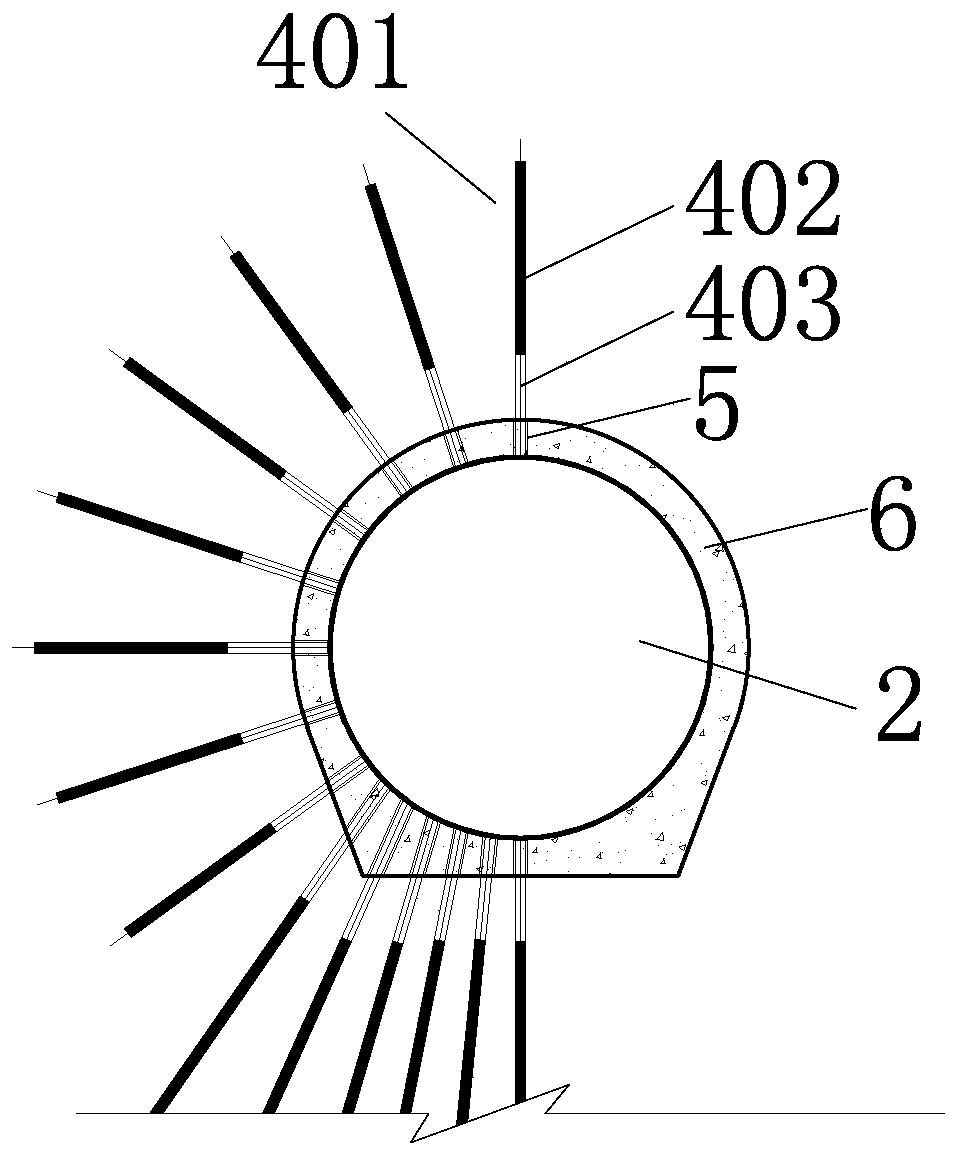

[0024] Such as figure 1 , figure 2 , image 3 As shown, the anti-seepage treatment structure of a kind of grouting curtain of the present invention and the diversion pipeline intersection is characterized in that it includes a grouting gallery 1, a diversion pipeline 2, a grouting curtain 3 and a ring-direction consolidation curtain 4, and the water diversion pipeline A grouting gallery 1 is respectively arranged above and below the 2, and the grouting curtain 3 extends from the grouting gallery 1 above to the grouting gallery 1 below. The water diversion pipeline 2 passes through the grouting curtain 3 , and the circumferential consolidation and curtain 4 is arranged around the water diversion pipeline 2 and overlapped with the grouting curtain 3 .

[0025] The circumferential consolidation and curtain 4 includes a circumferential curtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com