PTFE (Polytetrafluoroethylene) film roof transitional region waterproof cover opening and construction method thereof

A PTFE, waterproof cover technology, applied in roofs, building components, buildings, etc., can solve the problems of high strength requirements of the connection parts, the degree of matching needs to be improved, and the potential quality risks are prone to occur, so as to reduce the hidden danger of water seepage and reduce the risk of leakage. , to avoid the effect of seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0026] It should be noted that, unless otherwise clearly stipulated and limited, the terms "first", "second" and the like do not represent sequential installation, nor do they represent the importance of the described components.

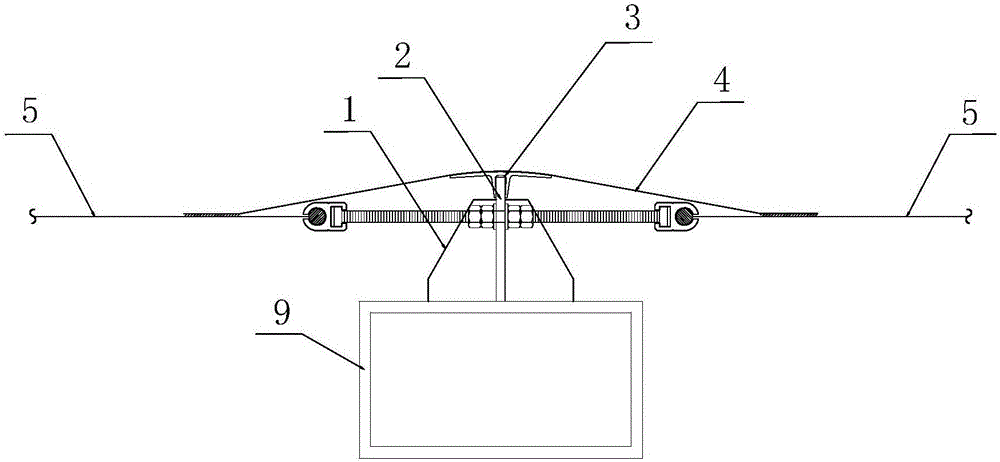

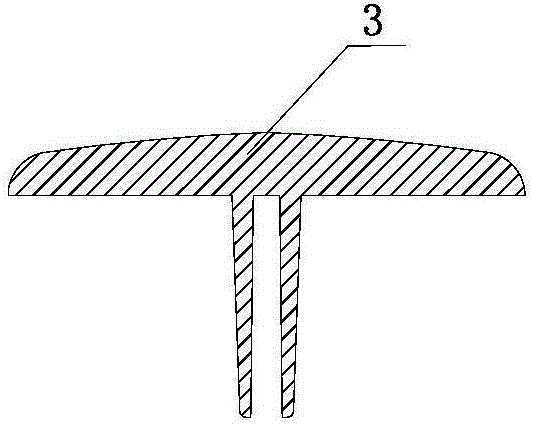

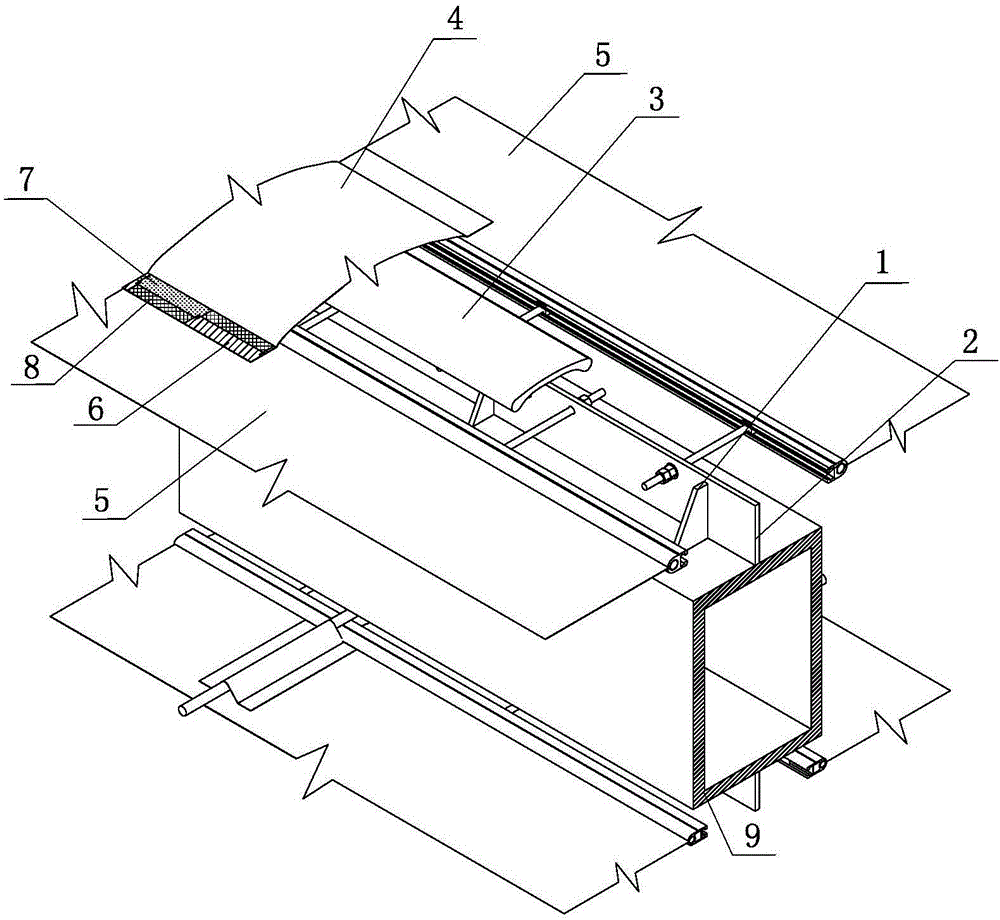

[0027] see Figure 1-Figure 4 , a PTFE membrane roof transition area waterproof cover, including PTFE cover membrane 4, membrane-connected plate 2, stiffener 1 and membrane cover support member 3, and the membrane-connected plate is vertically fixed on the upper top of roof beam 9 A plurality of stiffening ribs are fixed on both sides of the membrane-connected plate, and a membrane cover support is installed on the upper part of the membrane-connected plate, and a high-strength fiber PTFE cover membrane is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com