Multi-directional adjustable space grid support for easy overall assembly

A space grid and support technology, which is applied in the direction of architecture and building structure, can solve the problems of inconvenient design and construction installation work, complex nodes, and difficulty in positioning, so as to reduce design analysis work and widely apply and promote the prospect , The effect of reducing the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

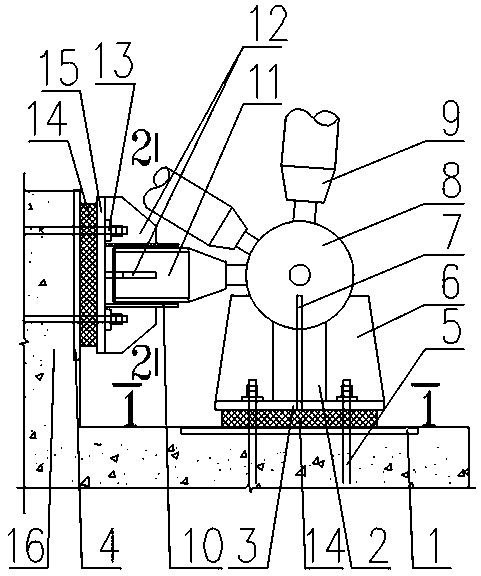

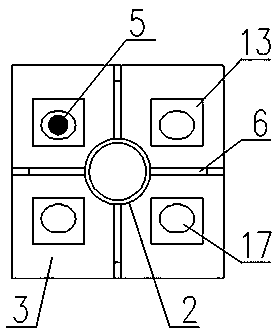

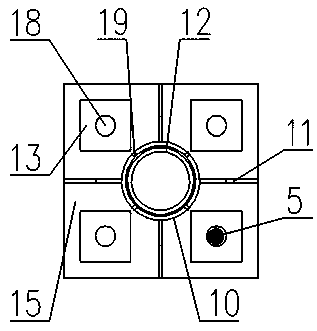

[0036] Such as Figure 1~3 As shown, a multi-directional adjustable space grid support that is convenient for overall assembly includes a vertical support bottom plate 3 and a lateral support bottom plate 15 that are fixed on a reinforced concrete support 16 and are perpendicular to each other. The upper end of the seat bottom plate 3 is provided with a support ball 8, and the side wall of the lateral support bottom plate 15 is provided with a steel pipe sleeve 10, and the steel pipe sleeve 10 is provided with a telescopic steel pipe 11 along the span direction, and one end of the steel pipe 11 is connected to the Bearing ball 8 is fixed, and its outer wall is welded with steel pipe sleeve 10.

[0037] The bearing ball 8 is a bolt ball or a welding ball.

[0038] The steel pipe 11 is a tapered steel pipe connected with a bolt ball or a supporting steel pipe con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com