Steel beam-steel pipe concrete column joint based on damage control concept

A technology of concrete-filled steel tube columns and joints, which is applied in the direction of architecture and building construction, and can solve problems such as difficult control of joint bending moment and shear force ratio, influence on joint energy consumption capacity and ductility, joint damage, etc., and achieve fast construction speed , Dissipate the input energy of the earthquake and avoid the effect of weld damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

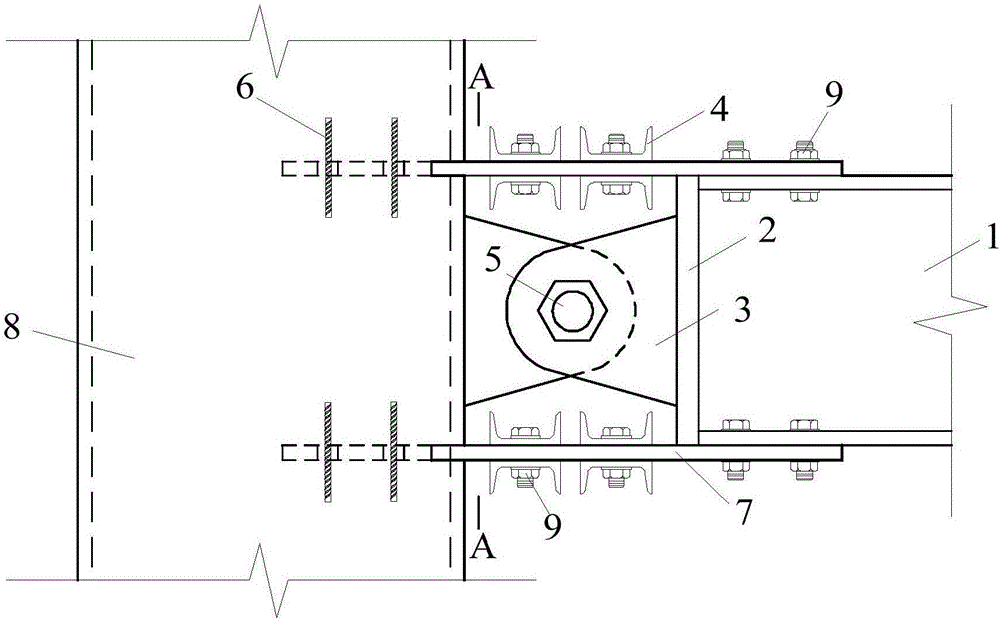

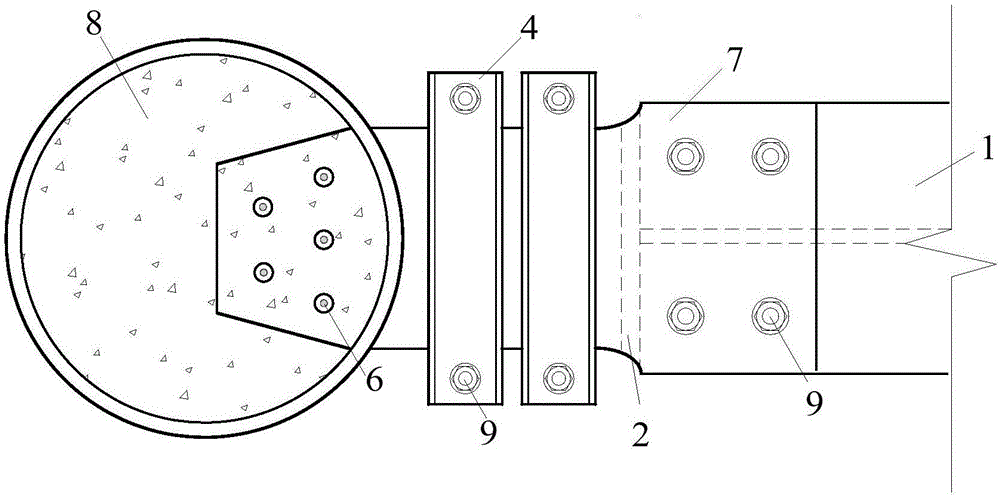

[0021] As shown in the accompanying drawings, the present invention is an energy-dissipating steel beam-concrete steel tube column joint, which consists of H-shaped steel in the steel beam, steel beam end plates, ear plates, channel steel, pins with nuts, steel bars, low It is composed of steel plate at yield point, steel pipe in steel pipe concrete column, and high-strength bolts. Its assembly procedure is as follows:

[0022] Factory prefabricated:

[0023] a. Prefabricate the basic components of the joint in the factory: H-shaped steel in the steel beam 1, steel beam end plate 2, ear plate 3, channel steel 4, pin shaft with nut 5, steel bar 6, steel plate with low yield point 7, Steel pipe 8 in steel pipe concrete column;

[0024] b. Open round holes on the upper and lower flanges of H-shaped steel 1 in the shaped steel beam, open round holes on the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com