A superimposed composite shear wall with two-stage stress characteristics

A technology for combining shear walls and shear walls, applied to walls, buildings, building components, etc., to achieve the effects of reliable connection, high manufacturing quality and precision, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

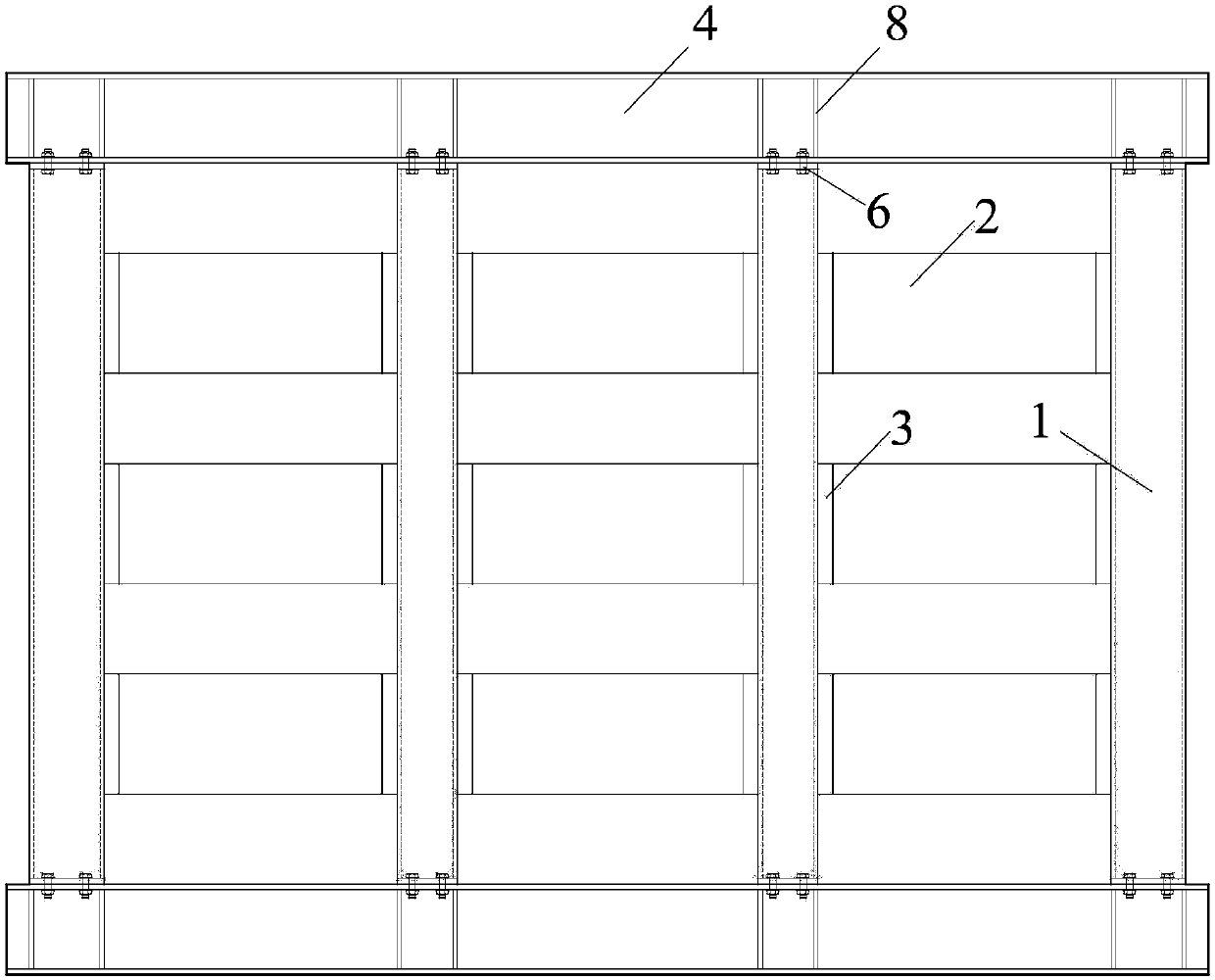

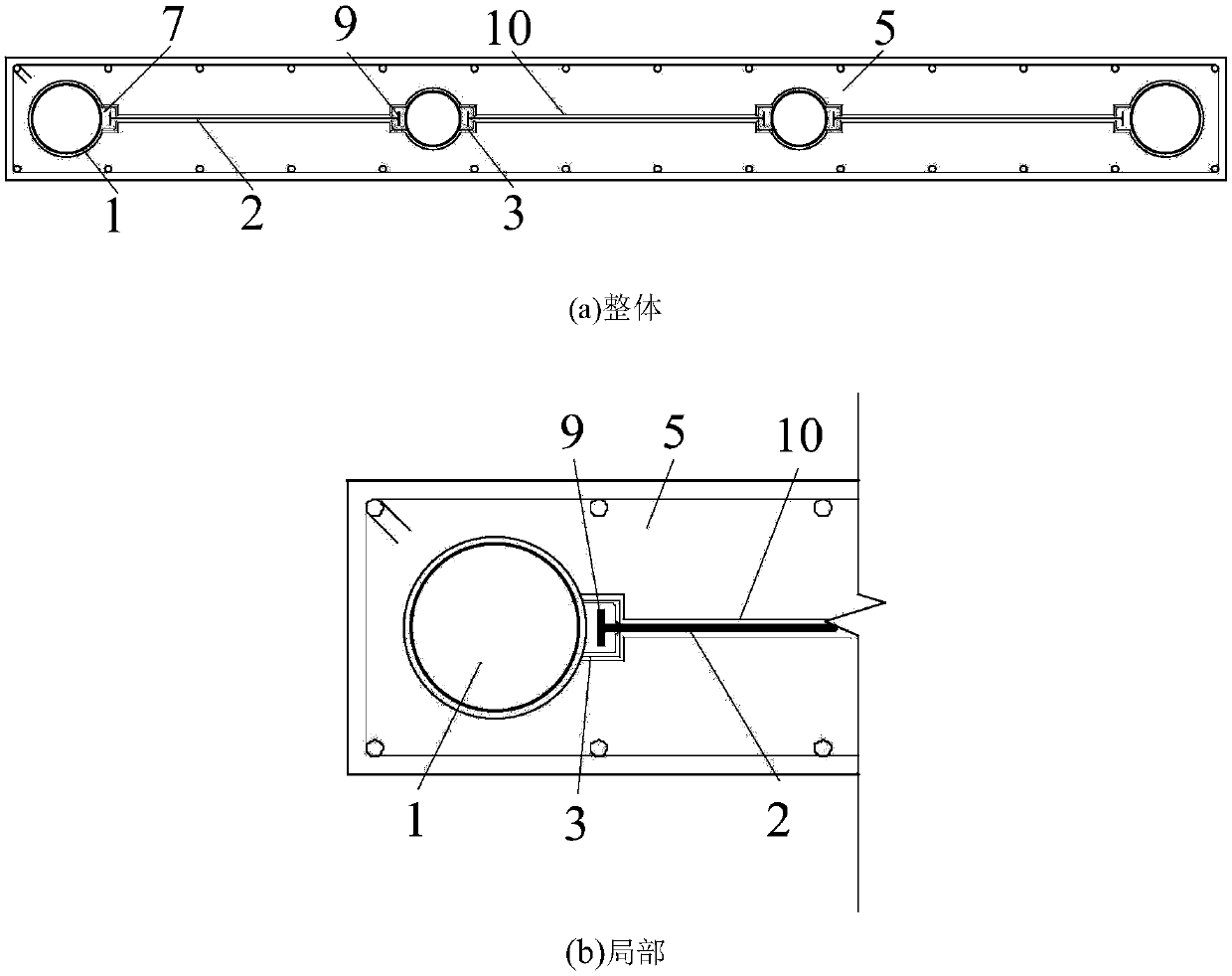

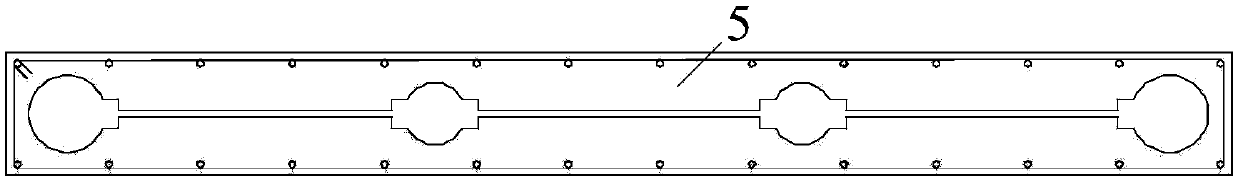

[0020] As shown in the accompanying drawings, the present invention is a superimposed composite shear wall with two-stage stress characteristics, which is composed of prefabricated steel tube concrete columns, low yield point steel plate connecting beams, double angle steel, H-shaped steel in frame beams, and prefabricated hollow steel bars. Concrete shear wall panels, high-strength bolts, post-cast concrete strips, stiffeners in frame beams, T-shaped end plates, and plastic films. Its assembly procedure is as follows:

[0021] Factory prefabricated:

[0022] a. Prefabricate the basic components of the composite shear wall in the factory: prefabricated steel tube concrete column (1), low yield point steel plate coupling beam (2), double angle steel (3), H-shaped steel in the frame beam (4), prefabricated hollow Reinforced concrete shear wall panels (5), hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com