Pillar-to-pillar connecting joint

A technology of joints and steel columns, applied in the field of building structures, can solve the problems of large labor costs, difficult to apply column-to-column connections, and lack of fusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with accompanying drawing:

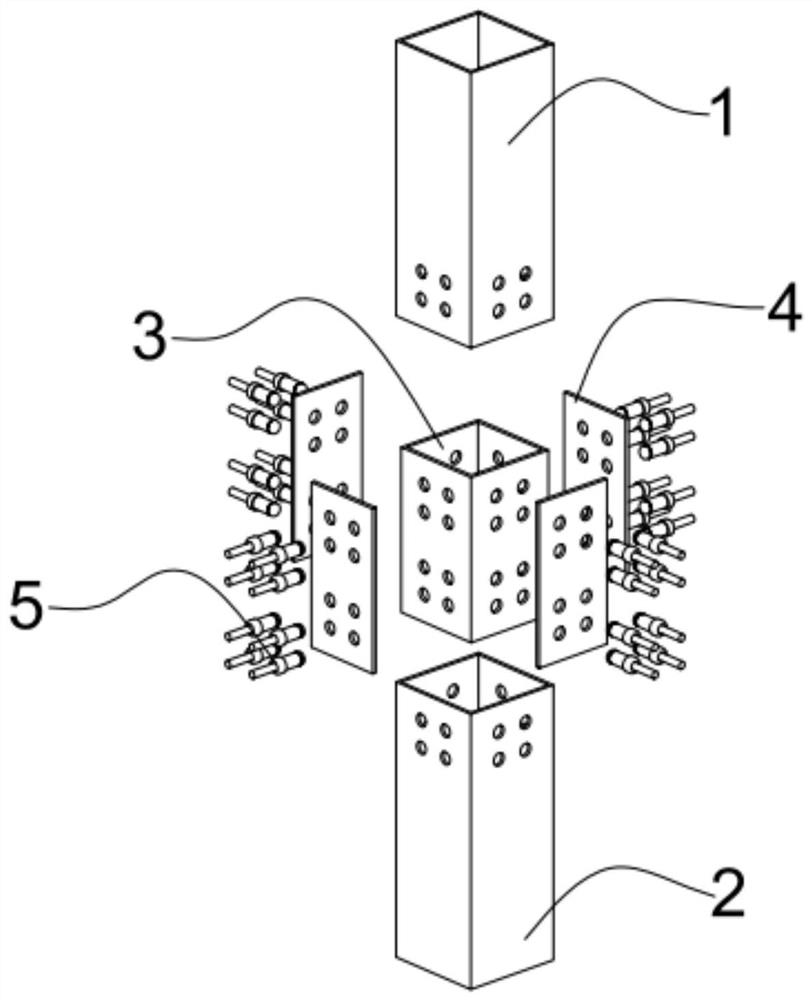

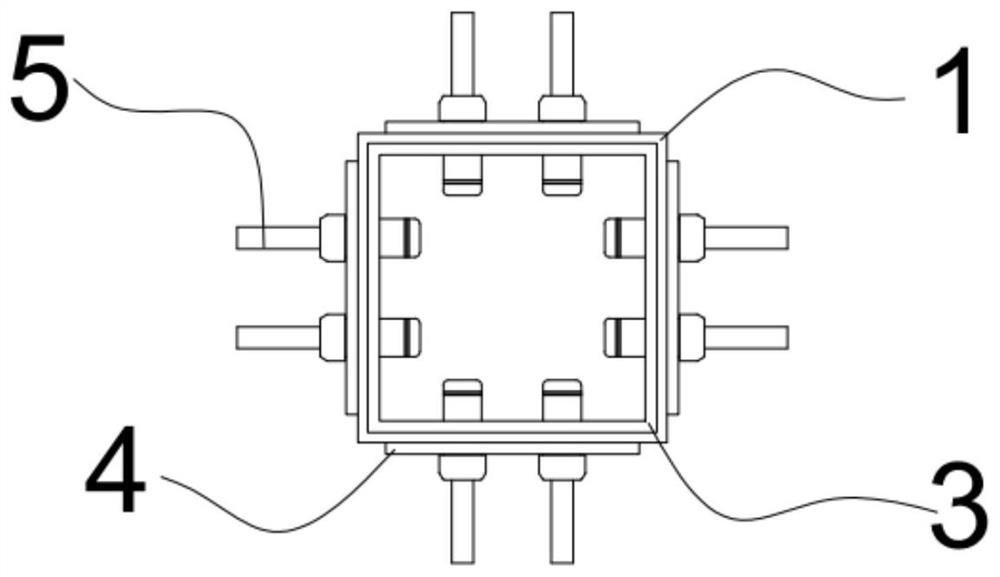

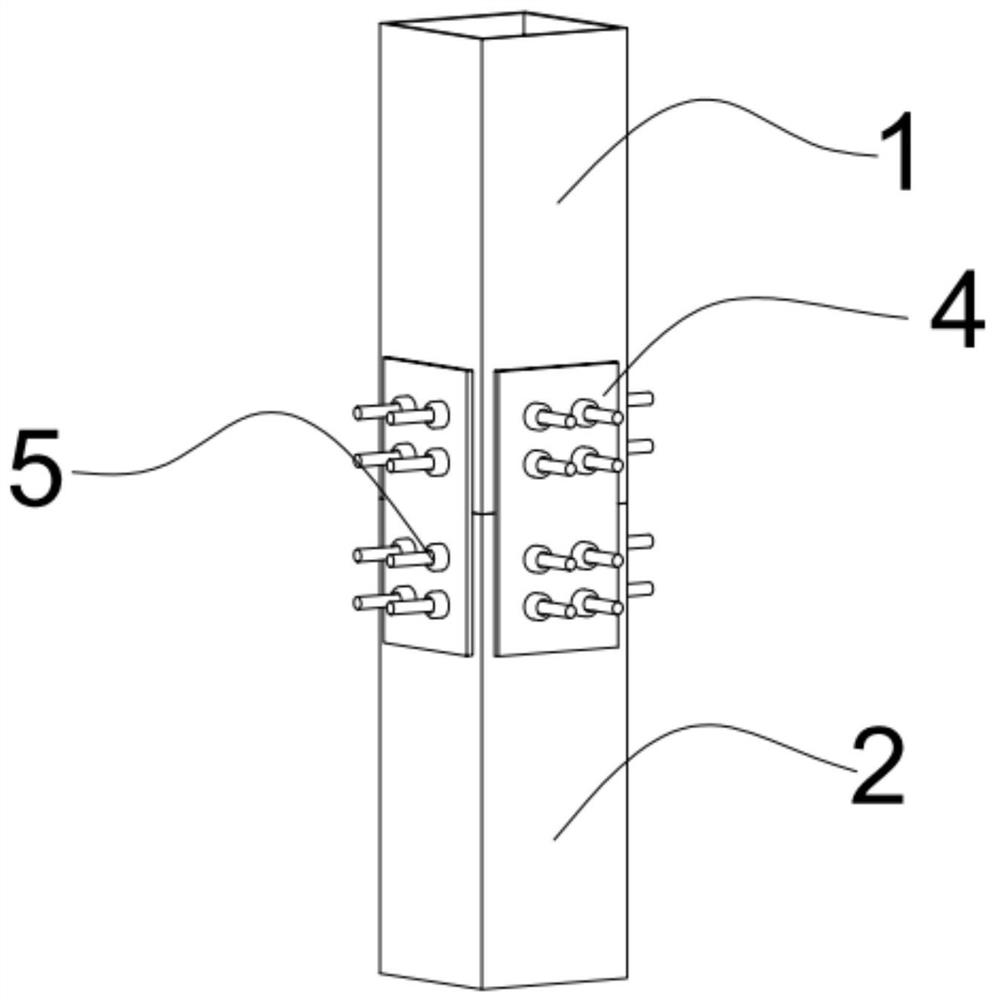

[0019] see Figure 1 to Figure 5 , a column-to-column joint, including a first steel column 1, a second steel column 2, a connecting piece 3, a ring groove rivet 5 and a connecting plate 4; the first steel column 1, the second steel column 2 and the connecting piece 3 are all It is a hollow column with the same structure. The first steel column 1 and the second steel column 2 are sleeved on both ends of the connecting piece 3 respectively. Fitting; the ends of the first steel column 1 and the second steel column 2 are in contact with each other, and several connecting plates 4 are arranged circumferentially at the contact position; the first steel column 1, the second steel column 2, the connecting plate 4 and the connection A number of bolt holes are arranged on the pieces 3, and the steel column, the connecting plate 4 and the connecting piece 3 are connected by ring groove r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com