Smooth and elastic finishing agent for nylon-cotton fabrics, and preparation method thereof

A technology for nylon-cotton fabrics and finishing agents, which is applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problem that the source and quality of modified polysiloxane cannot be well guaranteed, the finishing effect is difficult to last, and the product quality is not good. Stability and other issues, to achieve superior slippery and rebound, excellent slippery and delicate feeling, and improve the effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of nylon-cotton fabric slip elastic finishing agent

[0033] 1. Preparation process of double-ended epoxy modified silicone oil

[0034] The preparation method of epoxy-terminated silicone oil comprises the following steps in turn: add 500 g of octamethylcyclotetrasiloxane, 18.1 g of epoxy head-sealing agent, and 0.75 g of catalyst in the reaction flask, heat and stir at a speed of 45 rpm, Then raise the temperature to 70-75°C, vacuumize (-0.06-0.08MPa) for 15 minutes while raising the temperature, then continue to raise the temperature to 100-110°C for 6 hours, then raise the temperature to 140°C for 1 hour, and then vacuumize for 30 minutes (-0.08- 0.1MPa), the temperature is lowered to obtain epoxy-modified silicone oil.

[0035] 2. Preparation process of block silicone oil

[0036] Add 500g of epoxy-modified silicone oil into a four-necked flask equipped with a reflux device, and at a stirring speed of 45r / min, add 30.0g of ED900, 2.6...

Embodiment 2

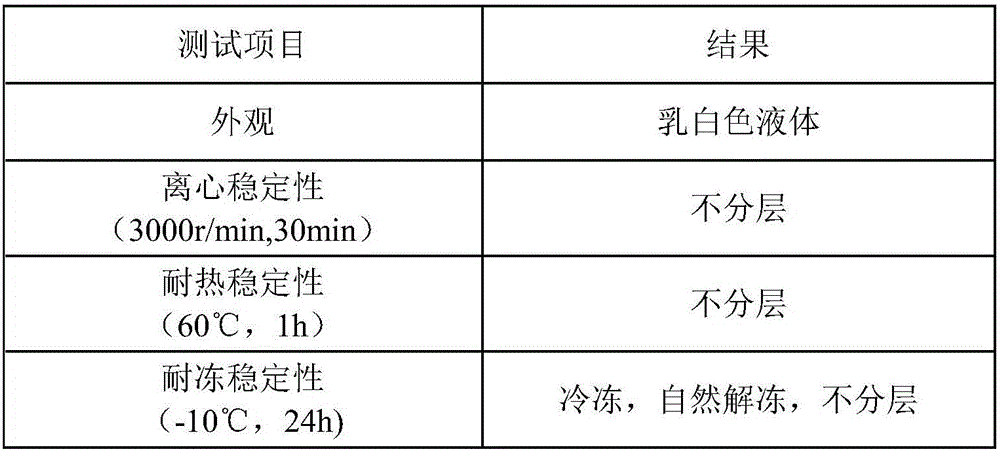

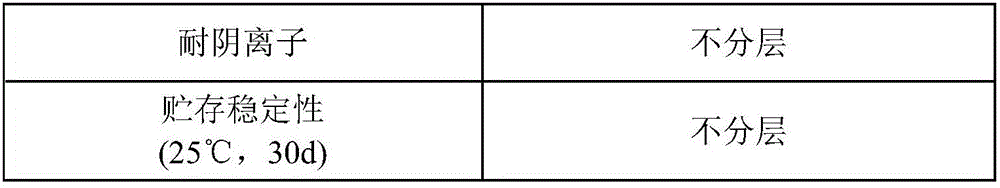

[0038] Add 350g of modified ternary copolymerized block silicone oil into the emulsification kettle, start stirring at 500 rpm, add emulsifier 53g TO5 and 114g TO7, and stir for 30 minutes; add 645g of water, add in 5 times, each time Stir for 5 minutes, with an interval of 5 minutes each time, to prepare the initial block silicone oil softener; add 5.8g of glacial acetic acid to the above reactant in 3 times, stir for 3-5min each time, add the remaining water 10 times, and let it sit and filter A slippery finishing agent for brocade cotton fabrics was obtained, the pH value of the slippery finishing agent was 5.8, and the solid content was 27.5%. Embodiment 2: the preparation of nylon-cotton fabric slippery finishing agent

[0039] 1. Preparation process of double-ended epoxy modified silicone oil

[0040] The preparation method of epoxy-terminated silicone oil comprises the following steps in turn: add 500 g of octamethylcyclotetrasiloxane, 13.9 g of epoxy head sealing agen...

Embodiment 3

[0045] Embodiment 3: the preparation of nylon-cotton fabric slippery finishing agent

[0046] 1. Preparation process of double-ended epoxy modified silicone oil

[0047] The preparation method of epoxy-terminated silicone oil comprises the following steps in turn: add 500 g of octamethylcyclotetrasiloxane, 11.31 g of epoxy head-sealing agent, and 0.75 g of catalyst in the reaction flask, heat and stir at a speed of 45 rpm, Then raise the temperature to 70-75°C, vacuumize (-0.06-0.08MPa) for 15 minutes while raising the temperature, then continue to raise the temperature to 100-110°C for 6 hours, then raise the temperature to 140°C for 1 hour, and then vacuumize for 30 minutes (-0.08- 0.1MPa), the temperature is lowered to obtain epoxy-modified silicone oil.

[0048] 2. Preparation process of block silicone oil

[0049] Add 500g of epoxy-terminated silicone oil into a four-necked flask equipped with a reflux device, and add 19.6g of ED900 and 11.25g of ED600 and 530g of ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com