Nylon composite powder material for selective laser sintering

A composite powder and laser sintering technology, applied in the field of selective laser sintering technology, can solve the problems of yellowing and easy oxidation of the workpiece surface, and achieve the effects of high sintering accuracy, enhancing the appearance and avoiding oxidation and yellowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

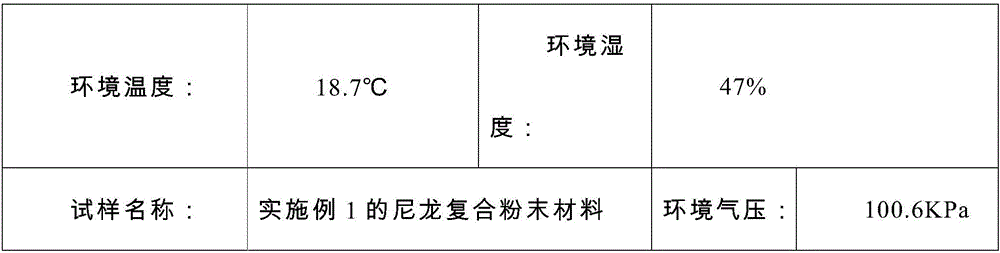

Embodiment 1

[0019] Weigh 80kg of nylon, 19.5kg of glass fiber, and 0.5kg of silver-white pearl powder and mix them evenly. The particle size of the nylon is 60 μm, the particle size of the glass fiber is 20 μm, and the particle size of the titanium dioxide is 60 μm; Laser sintering is carried out under the conditions of 40W, scanning speed of 12.7m / s, powder coating thickness of 0.1mm, and scanning distance of 0.3mm. The surface of the workpiece after sintering is white and bright, with high precision and no sintering warpage.

Embodiment 2

[0021] Weigh 70kg of nylon, 29kg of glass fiber, and 1kg of titanium dioxide and mix them uniformly. The particle size of the nylon is 50 μm, the particle size of the glass fiber is 40 μm, and the particle size of the titanium dioxide is 30 μm; Laser sintering was carried out under the conditions of scanning speed of 12.7m / s, powder coating thickness of 0.1mm, and scanning distance of 0.3mm. The surface of the workpiece after sintering is white and bright, with high precision and no sintering warpage.

Embodiment 3

[0023] Weigh 80kg of nylon, 19.5kg of glass fiber, and 0.5kg of white talc powder and mix them evenly. The particle size of the nylon is 55 μm, the particle size of the glass fiber is 30 μm, and the particle size of titanium dioxide is 40 μm; Laser sintering is carried out under the conditions of 42W, scanning speed of 12.7m / s, powder coating thickness of 0.1mm, and scanning distance of 0.3mm. The surface of the workpiece after sintering is white and bright, with high precision and no sintering warpage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com