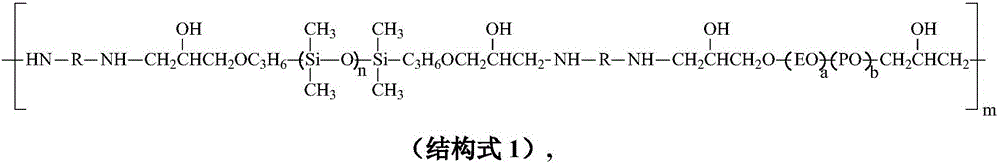

Double amino type block polyether amino silicone oil and preparation method thereof

A technology of diamino silicone oil and block polyether, which is applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve the problems of limiting the hand feeling of block polyether amino silicone oil, and solve the problems of hydrophilicity, hand feeling and better hand feeling. , improve the effect of polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

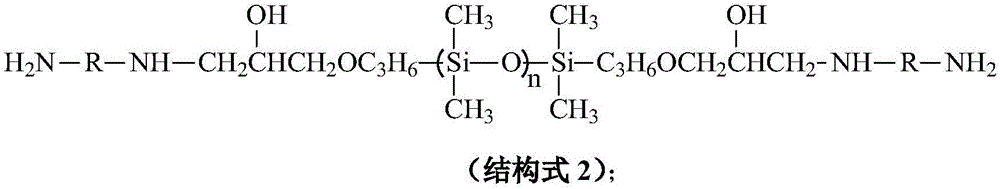

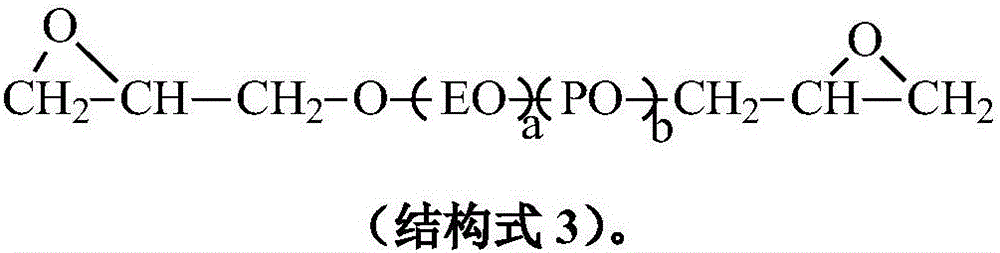

[0033] Add 45g of 1,3-propanediamine at one time to the reactor protected by nitrogen, and slowly add 36g of epoxy double-capped head under the condition of stirring, the addition is completed within 2h, stir at room temperature for 6h, then raise the temperature to 80°C, and continue to keep warm 8h; the excess diamine is extracted by vacuum distillation, and the amino double-head is obtained; the amino double-head and 700g organosiloxane ring body (DMC) prepared in the previous step are mixed evenly, and 0.7g (CH 3 ) 4 NOH (added in the form of alkali gel), raised the temperature to 100°C, and reacted for 15 hours; then raised the temperature to 140-150°C and reacted for 2 hours to decompose the catalyst, and distilled under reduced pressure to remove the low boilers to obtain α,ω-diamino Silicone oil: Add 92g epoxy-terminated polyether (molecular weight 920) and 560g isopropanol to the reaction system, react at 80°C for 20h, neutralize with organic acid to pH=7, and obtain ...

Embodiment 2

[0035] Add 53g of 1,4-butanediamine at one time into the nitrogen-protected reactor, slowly add 36g of epoxy double-capped head under stirring condition, complete the addition within 2h, stir at room temperature for 6h, then raise the temperature to 80°C, and continue to keep warm 8h; the excess diamine is extracted by vacuum distillation, and the amino double-head is obtained; the amino double-head and 955g organosiloxane ring body (DMC) prepared in the previous step are mixed uniformly, and 0.9g (CH 3 ) 4 NOH (added in the form of alkali gel), raised the temperature to 80°C, and reacted for 18 hours; then raised the temperature to 150°C, and reacted for 1 hour to decompose the catalyst, and distilled under reduced pressure to remove the low boilers to obtain α,ω-diaminosilicone oil; Add 185g epoxy-terminated polyether (molecular weight 1850), 500g isopropanol and 300g ethylene glycol monobutyl ether to the reaction system, react at 60°C for 20h, neutralize with organic acid ...

Embodiment 3

[0037] Add 50g of 1,3-propanediamine at one time into the nitrogen-protected reactor, slowly add 36g of epoxy double-capped head under the condition of stirring, complete the addition within 2h, stir at room temperature for 6h, then raise the temperature to 80°C, and continue to keep warm 8h; the excess diamine is extracted by vacuum distillation, and the amino double head is obtained; the amino double head prepared in the previous step and 1160g organosiloxane ring body (DMC) are mixed evenly, and 1g (CH 3 ) 4 NOH (added in the form of alkali gel), heated up to 110°C, and reacted for 16 hours; then heated up to 140-150°C, reacted for 1 hour to decompose the catalyst, and distilled under reduced pressure to remove low boilers to obtain α,ω-diaminosilicone oil; Add 92g epoxy-terminated polyether (molecular weight 920) and 1500g isopropanol to the reaction system, react at 60°C for 15h, neutralize with organic acid to pH=6~7, and obtain diamino type block polyether amino silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com