Composite reaction medium for removing nitrogen and phosphorus from underground water permeable reactive barriers and method for preparing composite reaction medium

A technology of reaction medium and reaction grid, applied in the field of water treatment, can solve unknown problems, achieve high compressive strength, solve the effect of loose surface structure and abundant reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Nitrogen and phosphorus removal composite reaction medium

[0054] I. Four kinds of raw materials of zeolite, bentonite, attapulgite and slag are obtained through crushing (4 meshes of particle size after sieving)-crushing (60 meshes of particle size after sieving)-ultrafine grinding (300 meshes of particle size after sieving) respectively to obtain raw material powder body.

[0055] II. According to claim zeolite: bentonite: attapulgite: coal cinder = 2: 1: 1: 2 by weighing the raw material powder and stirring.

[0056] III. Put the mixture obtained in step II into a granulator to make 3-30 mesh granules.

[0057] IV. Dry at 60°C for 10 hours.

[0058] V. Baking at 600°C for 4h.

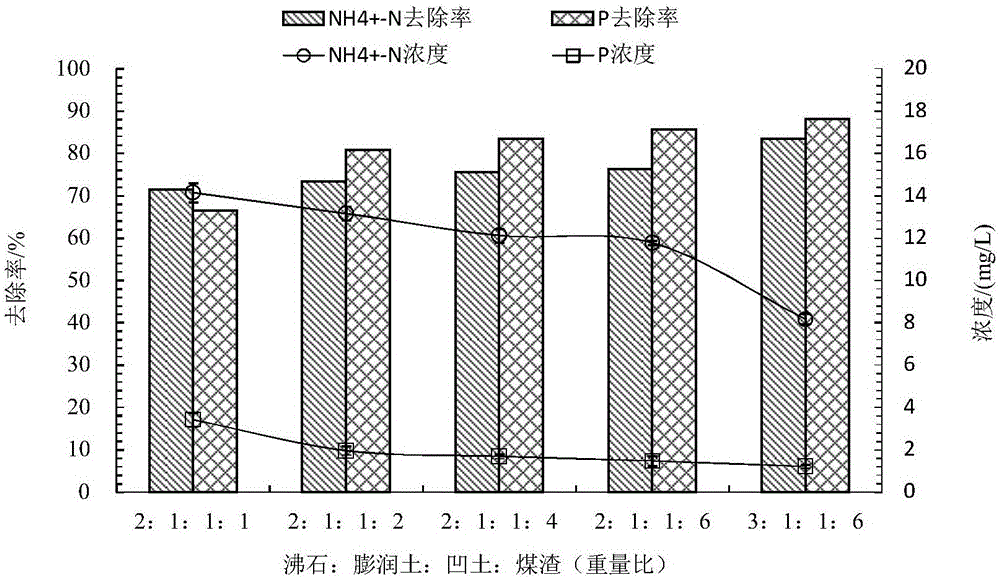

[0059] products such as figure 1 As shown, the composite reaction medium in the initial NH 4 + -Under the conditions of N concentration 46.44±3.83mg / L and P concentration 11.76±0.44mg / L, it can remove ≥80.2% NH 4 + -N (t ≥ 0.5h) and ≥ 93.2% of P (t ≥ 0.5h), and caused an inc...

Embodiment 2

[0061] I. Four kinds of raw materials of zeolite, bentonite, attapulgite and slag are obtained through crushing (4 meshes of particle size after sieving)-crushing (60 meshes of particle size after sieving)-ultrafine grinding (300 meshes of particle size after sieving) respectively to obtain raw material powder body.

[0062] II. According to claim zeolite: bentonite: attapulgite: coal cinder=2:1:1:1 weight ratio takes raw material powder and stirs and mixes.

[0063] III. Put the mixture obtained in step II into a granulator to make 3-30 mesh granules.

[0064] IV. Dry at 60°C for 8 hours.

[0065] V. Baking at 600°C for 3h.

Embodiment 3

[0067] I. Four kinds of raw materials of zeolite, bentonite, attapulgite and slag are obtained through crushing (4 meshes of particle size after sieving)-crushing (60 meshes of particle size after sieving)-ultrafine grinding (300 meshes of particle size after sieving) respectively to obtain raw material powder body.

[0068] II. According to claim zeolite: bentonite: attapulgite: cinder = 2: 1: 1: 4 weight ratio to take raw material powder and stir.

[0069] III. Put the mixture obtained in step II into a granulator to make 3-30 mesh granules.

[0070] IV. Dry at 55°C for 10h.

[0071] V. Baking at 700°C for 3h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com