A kind of activated carbon particle electrode modified by quinone compound and its preparation method and application

A particle electrode and activated carbon technology, applied in the field of environmental engineering, can solve the problems of poor applicability, many factors affecting the load, and complicated preparation methods, so as to be suitable for industrial production and popularization and application, improve valence conversion efficiency, and biocompatibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

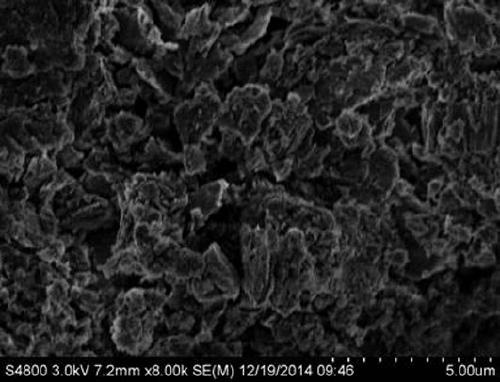

[0032] Preparation Example 1 Preparation of Activated Carbon Particle Electrode Modified by Quinone Compounds

[0033]Weigh 30g of activated carbon powder and 2.5g of 1,4-dihydroxyanthraquinone powder and mix them, and mix the activated carbon powder and 1,4-dihydroxyanthraquinone with ultrasonic vibration to obtain a mixed powder; dilute 10g with 10mL of absolute ethanol E-44 type epoxy resin, stir evenly to obtain diluted adhesive, add the diluted adhesive to the mixed powder, then add 10g of polyamide resin as curing agent, stir to form a mixed paste, mix Put the paste into a household noodle press and press out uniform strips, then break it into particles of the same size, and dry it at room temperature to obtain an activated carbon particle electrode modified by quinone compounds. Further, wash the dried particle electrode with distilled water, Then put it into a vacuum drying oven, solidify and dry at 105° C. for 24 hours to obtain a pure cured quinone compound-modified ...

preparation Embodiment 2

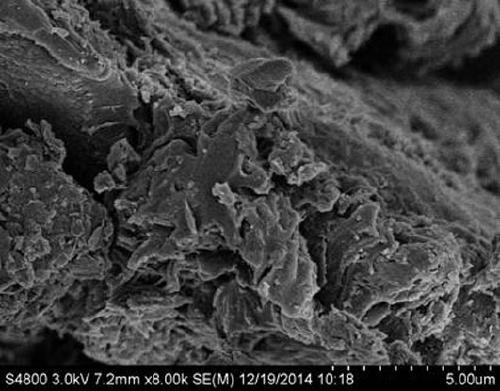

[0034] Preparation Example 2 Preparation of Activated Carbon Particle Electrode Modified by Quinone Compounds

[0035] Weigh 20g of activated carbon powder and 2g of 1,4-dihydroxyanthraquinone powder and mix them, and mix the activated carbon powder and 1,4-dihydroxyanthraquinone with ultrasonic vibration to obtain a mixed powder; dilute 8g of Ethanol with 7mL of absolute ethanol -44 type epoxy resin, stir evenly to obtain diluted adhesive, add the diluted adhesive to the mixed powder, then add 7g of polyamide resin as curing agent, stir evenly to form a mixed paste, mix the mixed paste Put the body into a household noodle press to press out uniform strips, then break it into particles of the same size, and dry it at room temperature to obtain an activated carbon particle electrode modified by quinone compounds. Further, wash the dried particle electrode with distilled water, and then Put it into a vacuum drying oven, cure and dry at 105° C. for 24 hours to obtain a pure cured...

preparation Embodiment 3

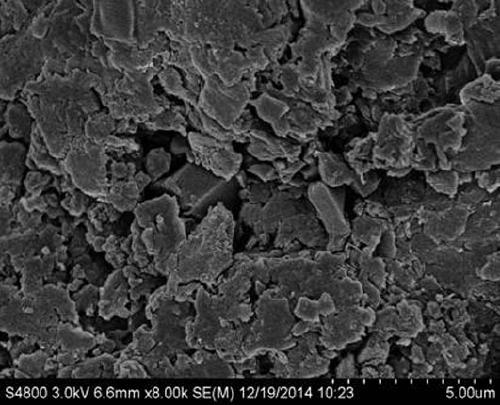

[0036] Preparation Example 3 Preparation of Activated Carbon Particle Electrode

[0037] Dilute 10g of E-44 type epoxy resin with 10mL of absolute ethanol, stir evenly to obtain the diluted adhesive, add the diluted adhesive to 30g of activated carbon powder, then add 10g of polyamide resin as a curing agent, and stir evenly After becoming a paste, put the paste into a household noodle press and press out uniform strips, then break it into particles of the same size, dry it at room temperature to obtain an activated carbon particle electrode, and further, wash the dried activated carbon particle electrode with distilled water After washing, put it into a vacuum drying oven, solidify and dry at 105°C for 24 hours to obtain a pure solidified activated carbon particle electrode.

[0038] With the commercially available activated carbon particle electrode purchased as a negative control, the activated carbon particle electrode prepared in Example 3 was used as a blank control, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com