Gradient technology method for wet process phosphoric acid production

A technology of wet-process phosphoric acid and process methods, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of long phosphoric acid leaching time, poor filtration effect, high residual phosphorus content of phosphogypsum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The chemical composition of Hubei Phosphate Rock A is as follows: P 2 o 5 Content 31.26%, CaO content 46.24% (Wt%).

[0036] The specific operation steps of the gradient process of wet-process phosphoric acid production are as follows:

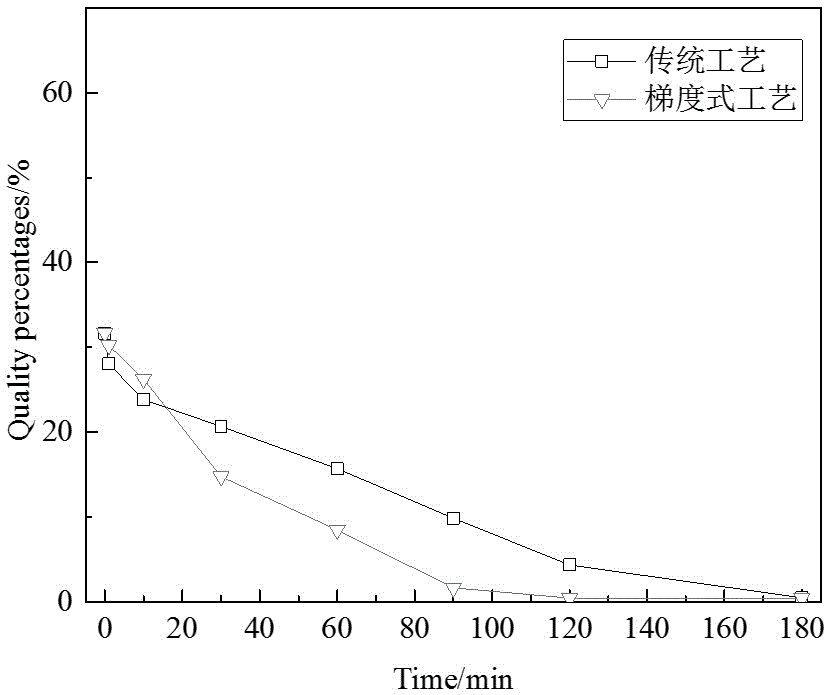

[0037] There are three stages in acid hydrolysis and leaching of phosphate rock. The first stage is the rapid reaction stage, the second stage is the stable reaction stage, and the third stage is the solid crystal growth stage.

[0038] 1. Adjust the formula

[0039] According to the reaction characteristics of phosphate rock A, the ratio (molar ratio) of the phosphate rock and sulfuric acid that needs to be added twice is preferred, specifically as follows:

[0040] the first time the second time h 3 PO 4 :H 2 SO 4

1:0.7 0.2:1

[0041] 2. Rapid response stage

[0042] Add 40g of phosphate rock and 33g of high phosphorus mixed acid (phosphoric acid 19.41g, sulfuric acid 13.59g, the molar ratio of ...

Embodiment 2

[0053] The chemical composition of Hubei phosphate rock B is as follows: P 2 o 5 Content 30.18%, CaO content 44.51% (Wt%).

[0054] The specific operation steps of the gradient process of wet-process phosphoric acid production are as follows:

[0055] There are three stages in acid hydrolysis and leaching of phosphate rock. The first stage is the rapid reaction stage, the second stage is the stable reaction stage, and the third stage is the solid crystal growth stage.

[0056] 1. Adjust the formula

[0057] According to the reaction characteristics of phosphate rock B, the ratio (molar ratio) of the phosphate rock and sulfuric acid that needs to be added twice is optimized, specifically as follows:

[0058] the first time the second time h 3 PO 4 :H 2 SO 4

1:0.6 0.3:1

[0059] 2. Rapid response stage

[0060] Add 40g of phosphate rock and 31.91g of high phosphorus mixed acid (19.94g of phosphoric acid, 11.17g of sulfuric acid, the molar ...

Embodiment 3

[0071] The chemical composition of Hubei phosphate rock C is as follows: P 2 o 5 Content 30.02%, CaO content 43.90% (Wt%).

[0072] The specific operation steps of the gradient process of wet-process phosphoric acid production are as follows:

[0073] There are three stages in acid hydrolysis and leaching of phosphate rock. The first stage is the rapid reaction stage, the second stage is the stable reaction stage, and the third stage is the solid crystal growth stage.

[0074] 1. Adjust the formula

[0075] According to the reaction characteristics of phosphate rock C, the ratio (molar ratio) of the phosphate rock and sulfuric acid that needs to be added twice is preferred, specifically as follows:

[0076] the first time the second time h 3 PO 4 :H 2 SO 4

1:0.6 0.3:1

[0077] 2. Rapid response stage

[0078] Add 40g of phosphate rock and 31.33g of high phosphorus mixed acid (19.58g of phosphoric acid, 11.75g of sulfuric acid, the mola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com