An automatic box sealing machine

A carton sealing machine, automatic technology, applied in packaging sealing/fastening, transportation packaging, thin material handling, etc., can solve the problems affecting the stability and reliability of equipment, complicated control systems, and high manufacturing costs, and achieve stable working process. Reliable, scientific and reasonable structural design, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

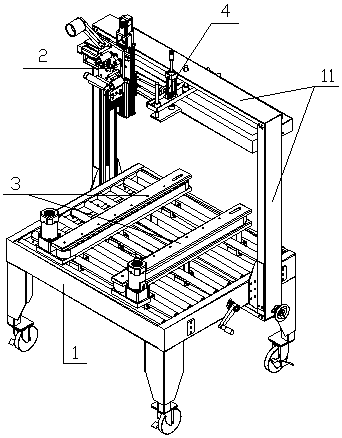

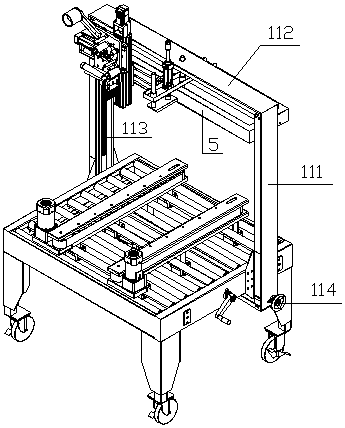

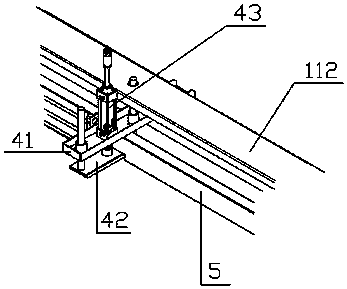

[0047] Embodiment: a kind of automatic box sealing machine, as Figure 1-9 As shown, it includes a frame 1, a box sealing mechanism 2, a box guiding mechanism 3, a pressing mechanism 4, sensors and a control system. The sealing mechanism 2, the box guiding mechanism 3 and the pressing mechanism 4 are all arranged on the frame 1, and the position information of the material is sensed by the sensor, and the operation of the entire automatic sealing machine is controlled by the control system. The working platform of frame 1 is a roller platform, which is convenient for the transmission of the box body. The box guiding mechanism 3 is arranged on the roller platform, and the top of the frame 1 is provided with a mechanism supporting frame 11 . The mechanism support frame 11 includes two columns 111 vertically fixed on both sides of the frame (in the case that it is inconvenient to mark in multiple places, only one place is marked in the same member figure as a representative, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com