Flood discharge gate and flood discharge system

A flood discharge gate and flood discharge technology, which is applied in sea area engineering, construction, barrage/weir, etc., can solve the problems of unsatisfactory mechanical properties of flat gates and arc gates, reduce thickness, meet sealing requirements, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

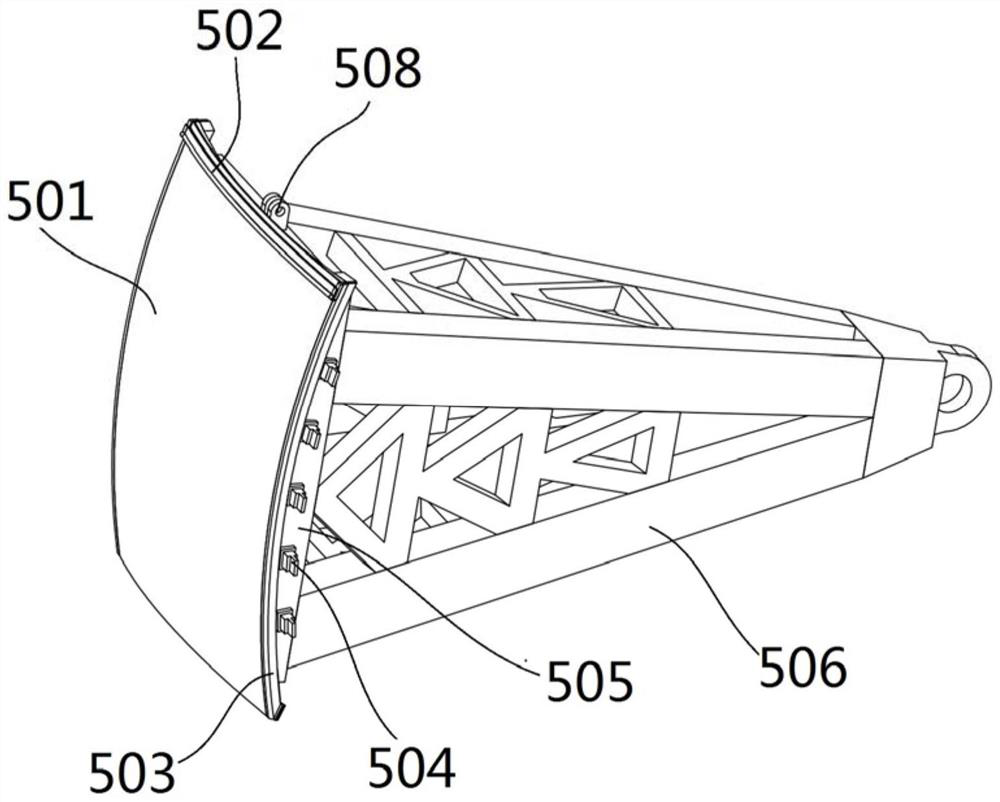

[0060] This embodiment provides a flood gate 500, such as figure 1 , 2 As shown, it includes a panel structure that is rotatably blocked on the flood discharge hole 402, the panel structure has a panel body 501, the direction of the panel body 501 facing the water flow is the water-facing surface, and the water-facing surface of the panel body 501 is at least two It is arc-shaped in different directions; at the same time, a support structure is arranged on the side of the panel body away from the water-facing surface, one end of the support structure is connected with the side of the panel body away from the water-facing surface, and the other end is connected to the side wall of the flood discharge hole. The support blocks are connected in rotation, and the setting of the support structure can increase the bearing capacity of the panel body 501;

[0061] When a surface is under pressure, in theory, the more severe the bending, the greater the pressure it can withstand; when ...

Embodiment 2

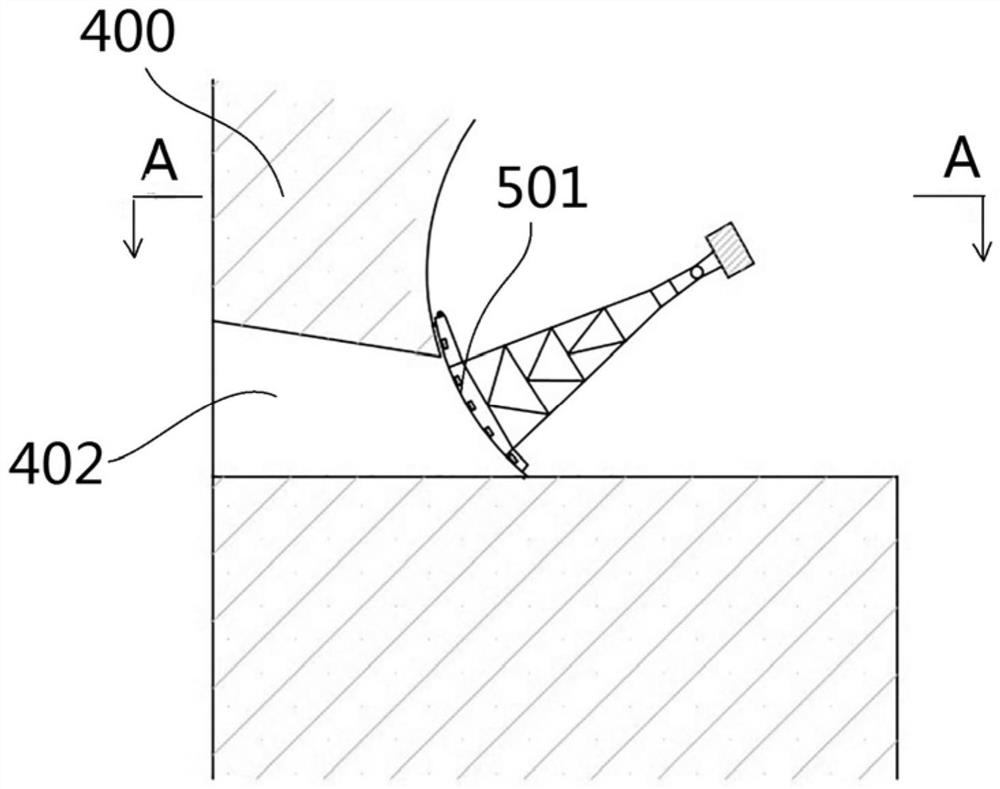

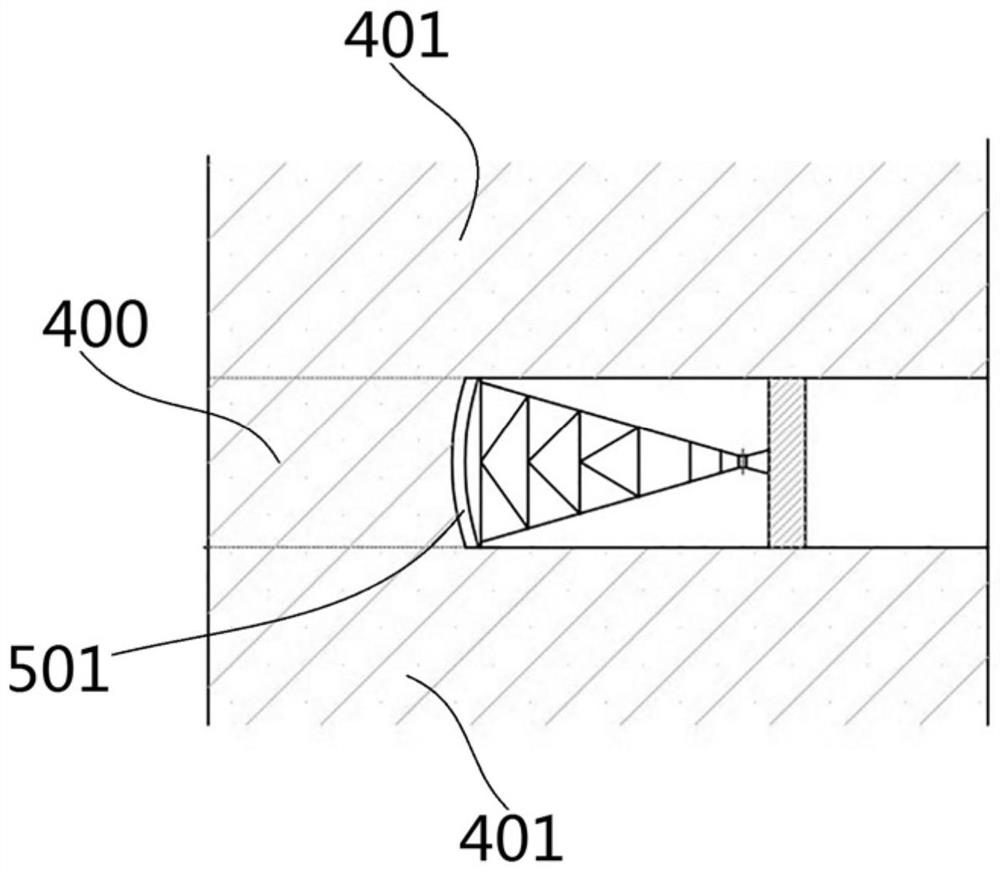

[0069] This embodiment provides a flood discharge system, such as Figure 4 , 5 As shown in the figure, it includes a lock chamber, and a flood discharge hole is opened on the lock chamber; the flood discharge gate 500 described in the embodiment is rotated and arranged in the lock chamber; There is a second state that avoids the opening of the spill hole.

[0070] The upper end of the flood discharge hole is the lintel 400 of the flood discharge hole. The matching surface of the flood discharge hole lintel 400 and the panel body is an arc surface, and the matching surface of the flood discharge hole lintel 400 is matched with the upstream surface of the panel body. Lintel 400 turn setting.

[0071] A sealing plate 403 protruding toward the panel body is provided on the flood discharge hole lintel 400, and cooperates with the top water stop 502. When the panel body is blocked in the flood discharge hole, the flood discharge hole lintel 400 and the panel body are sealed again...

Embodiment 3

[0074] This embodiment provides a water jet prevention device, which is applied in the flood discharge system in the second embodiment. This embodiment provides a water jet-proof sealing device, which is suitable for sealing the hyperboloid gate 500, such as Image 6 , 7 As shown, it includes: a movable water seal assembly 100, a fixed water seal assembly 200 and a drive assembly 300; one end of the fixed water seal assembly 200 is connected to the lintel 400 of the flood discharge hole, and the other end is provided with a movable water seal assembly 100. The movable water seal assembly 100 is driven by the drive assembly 300 to move the fixed water seal assembly 200; the movable water seal assembly 100 has a main seal 102, and the shape of the main seal 102 matches the shape of the panel of the gate 500, which can achieve tightness Sealing; the drive assembly 300 has multiple groups, which are arranged at intervals along the extending direction of the fixed water seal assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com